What is OEE

OEE (Overall Equipment Effectiveness) in the Semiconductor industry is a TPM (Total Productive Maintenance) metric that measures how well a piece of equipment is performing compared to its maximum potential by combining availability, performance, and quality into a single measurement. As renowned industrial engineer, Shigeo Shingo, once said:

“The most dangerous kind of waste is the waste we do not recognize.”

Factories operate under immense pressure to produce high-quality wafers, dies, and packages at scale, while minimizing downtime, defects, and wasted resources. For decades, Overall Equipment Effectiveness (OEE) has been the go-to metric in manufacturing for measuring production efficiency. It tells how effectively equipment is being utilized and has been widely adopted across many industries.

However, traditional OEE’s single percentage measurement does not explain why losses happen or predict future issues thus advancements are needed to bring granularity, context, and forward-looking insight to fabs and OSATS.

What is Advanced OEE?

Advanced OEE (sometimes referred to as OEE 4.0) is an upgraded framework that incorporates AI analytics and automation to deliver real-time, predictive, and flexible optimizations in a semiconductor manufacturing process.

In this article, we’ll break down:

- What traditional OEE is and why it matters.

- The gaps and limitations of OEE in today’s fabs and OSATs.

- How advancements in OEE are building on top of traditional OEE processes with AI analytics, predictive modeling, and flexibility.

- Actionable ways fabs and OSATs can use Advanced OEE to reduce downtime, improve yield, and maximize ROI.

- How yieldWerx Real-Time Machine Control & Monitoring OEE product module makes Advanced OEE possible in practice.

The Basics: What OEE Measures

At its core, OEE is a composite metric that evaluates manufacturing efficiency based on three factors:

- Availability – the percentage of scheduled production time when equipment is actually running.

- Performance – the speed at which the equipment runs as compared to its ideal capacity.

- Quality – the proportion of good units produced versus total units manufactured.

The formula is straightforward:

OEE = Availability × Performance × Quality

A perfect score of 100% means your tools are running without downtime, at full speed, and producing only good parts. In reality, world-class manufacturers often operate closer to 75–80%.

OEE has been a trusted tool for decades because it gives managers a single score that highlights how much productive capacity is being realized versus lost. However the metric alone is not enough for modern complex production.

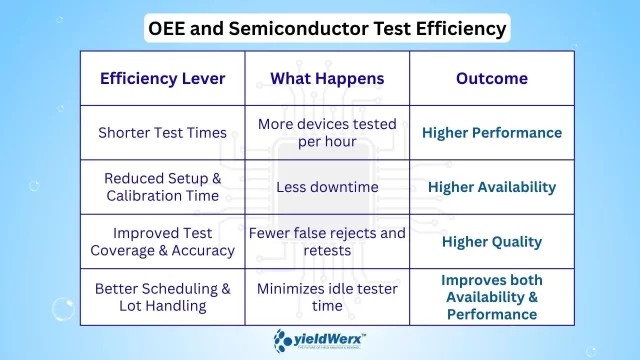

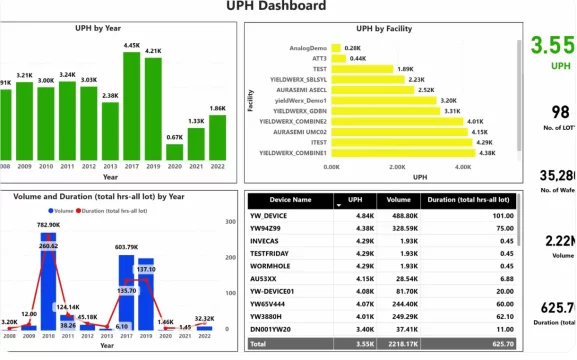

How Semiconductor Test Efficiency Drives OEE

In semiconductor test operations efficiency directly shapes Overall Equipment Effectiveness (OEE). Because OEE measures how well equipment is utilized, any improvement in test processes has a measurable impact on cost per die and time-to-market.

A Quick Example

Consider a wafer prober/tester that:

- Achieves 90% uptime (Availability)

- Operates at 85% of theoretical throughput (Performance)

- Delivers 98% good test results without false failures (Quality)

OEE = 0.90 × 0.85 × 0.98 ≈ 75%

By optimizing test times or reducing handler downtime, OEE can climb into the 80–90% range. This directly lowers the cost per tested die.

The Limits of Traditional OEE

OEE tells you how effective your equipment was over a given period—but it doesn’t tell you why performance dropped or how to prevent future losses. In today’s semiconductor environment, those blind spots come at a steep cost.

- It’s reactive, not predictive.

OEE measures past performance but doesn’t forecast failures or proactively suggest interventions. If a tool breaks down mid-shift, OEE will record the downtime—but by then, wafers and throughput have already been lost. - It penalizes flexibility.

In modern fabs and OSATs, frequent product changes are common due to customer-specific requirements, smaller lots, or shifting demand. Traditional OEE often penalizes these setups with lower availability and performance scores, even though flexibility is a strategic necessity. It isn’t well-suited for the age of mass customization. - It overlooks hidden losses.

Micro-stoppages, gradual wear, and operator variability can degrade output without being fully captured by traditional OEE metrics. These “invisible” inefficiencies add up to substantial lost capacity. Moreover, OEE numbers can be easily fudged. - It ignores system-wide context.

OEE is usually calculated at the machine level. In practice, bottlenecks arise from how tools, lines, and operators interact across the factory. Without a broader, data-driven view, optimization remains fragmented.

In short, OEE is excellent at measuring productivity losses, but it falls short of diagnosing, predicting, and adapting to the realities of next-generation semiconductor manufacturing.

Introducing Advanced OEE

Advanced OEE (OEE 4.0) takes OEE to the next level by embedding analytics, automation, AI/ML, and flexibility factors into the framework. It doesn’t just measure what happened—it predicts, explains, and optimizes what will happen next.

How does Advanced OEE Work?

Predictive Availability:

Instead of simply logging downtime, advanced OEE uses predictive analytics to forecast failures based on historical downtime patterns including vibration, temperature, pressure, and power data from tool sensors. Predicting possible failures can shift maintenance from reactive to proactive.

Performance Optimization:

AI-driven analytics continuously compare actual tool speeds against historical and ideal benchmarks, recommending fine-tuned settings, operator workflows, or process conditions to maximize throughput.

Quality Assurance in Real Time:

By analyzing multivariate data streams (e.g., chamber pressure, gas flow, or probe resistance), advanced OEE identifies quality drift early, adjusts parameters automatically, and reduces rework/scrap.

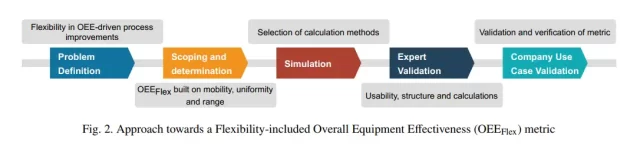

Flexibility Dimension:

Advanced OEE acknowledges the realities of mass customization. Instead of penalizing frequent product changes, it incorporates mobility, uniformity, and range to recognize equipment’s ability to adapt quickly across multiple products without compromising yield.

Actionable Benefits of Advanced OEE for Fabs and OSATs

1. Reduce Downtime with Predictive Maintenance

A 300mm fab can cost up to $10 billion, and unplanned downtime can cost millions of USD per hour. Advanced OEE reduces unplanned maintenance by shifting to predictive and prescriptive maintenance.

Tools are serviced based on actual health indicators, not just time intervals. This means measurable gains in fab productivity, while OSATs benefit from improved semiconductor test efficiency across diverse equipment fleets.

Action: Start by instrumenting critical tools with IoT sensors that monitor vibration, temperature, and current draw. Use analytics platforms to trigger predictive maintenance alerts before catastrophic failure.

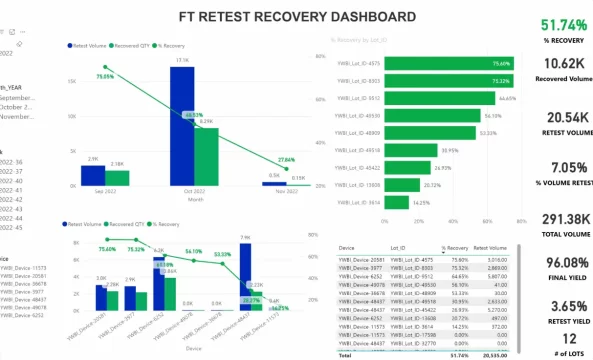

2. Improve Yield with Real-Time Quality Monitoring

Even a 1% yield loss can translate into millions in lost revenue. Advanced OEE leverages AI to analyze process drift and catch subtle defect drivers early.

Action: Deploy real-time anomaly detection on metrology and test data. Feed insights back into tool settings to correct drifts before they create scrap or rework.

3. Optimize Asset Utilization

Traditional OEE focuses on uptime, but advanced OEE looks at asset utilization in context—whether downtime can be postponed, sped up, or avoided. This helps maximize ROI on capital-intensive equipment.

Action: Use advanced OEE dashboards to identify bottleneck tools and simulate “what-if” maintenance scenarios (e.g., postponing PM to run high-priority lots without affecting quality).

4. Enable Flexible Manufacturing

Mass customization is becoming the norm. Advanced OEE incorporates flexibility metrics (mobility, uniformity, range) to measure not just productivity, but adaptability.

Action: Track how setup times, product mix variability, and start-up rejects affect OEE. Use these insights to justify investments in automation, operator training, or equipment upgrades that boost flexibility.

5. Drive Continuous Improvement with Analytics Feedback Loops

Unlike static OEE, advanced OEE integrates feedback loops where predictive models improve over time. This continuous learning creates more accurate forecasts and smarter optimization.

Action: Establish a data pipeline that feeds tool performance data into analytics models, validates predictions against outcomes, and updates thresholds automatically.

Why Moving Beyond OEE Is Critical Now

Semiconductor fabs and OSATs can no longer rely on retrospective metrics alone. With billions of dollars tied up in advanced equipment and demand for faster, cheaper, more customized products, the cost of inefficiency is too high.

- Predictive > Reactive: Manufacturers that embrace predictive maintenance see 20–25% higher throughput and 30–40% lower maintenance costs.

- Flexibility as a Differentiator: In high-mix, low-volume environments, the ability to adapt quickly is as valuable as raw productivity.

- Data Explosion: With millions of sensors in a fab generating terabytes of data per minute, advanced OEE provides the analytics layer needed to turn raw data into actionable insights.

According to McKinsey, improving equipment reliability in fabs can raise tool availability by over 15%. When focused on bottleneck tools, 70–80% of that gain translates into higher overall OEE. This unlocks more than 10% additional fab capacity without needing new tools or facilities.

Traditional OEE gives you a report card. Advanced OEE gives you a playbook for action.

yieldWerx Real-Time Machine Control & Monitoring: Enabling Advanced OEE

OEE software dashboards stop at reporting availability, performance, and quality. yieldWerx takes this much further with its Real-Time Machine Control & Monitoring module, which ingests data from any process, tester, handler/prober in real-time and applies statistical rules to detect deviations immediately. This creates an environment where engineers can analyze and respond to issues as they happen, rather than reacting after production losses occur. yieldWerx provides simple user interfaces to use Western Electric (WECO) rules and conduct ‘What-If‘ analysis.

Real-Time and Passive Control

Our advanced OEE software offers both passive monitoring and active real-time control, allowing manufacturers to view wafer maps, Device Under Test (DUT) data, and full parameter monitoring directly as equipment operates. This dual capability ensures that fabs and OSATs have the flexibility to either track trends silently or intervene instantly when equipment begins to drift from expected performance.

Adaptive Wafer Maps

One of the most powerful features of the module is the creation of adaptive wafer maps. Instead of forcing engineers to retest entire wafers, the system isolates only the defective test locations that require further verification. This targeted approach minimizes retest times and eliminates unnecessary touchdowns, directly improving semiconductor test efficiency while preserving throughput.

Overall Equipment Efficiency in Complex Environments

In fabs and OSATs, where testers, probers, handlers, and load boards all interact in complex ways, managing equipment health and throughput is a formidable challenge. The yieldWerx module provides immediate insight into machine performance, allowing operators to quickly address inefficiencies, reduce downtime, and maximize throughput. This ensures that equipment operates closer to its full potential, unlocking higher fab productivity and more consistent test equipment utilization.

Yield Prediction and RMA Analysis

The module goes beyond traditional OEE by utilizing AI/ML-assisted algorithms into yield analytics. Its yield prediction capabilities combine data across the product test supply chain to forecast potential yield losses early and guide root cause analysis. At the same time, the integrated RMA analysis function leverages the Lot Genealogy Module and AI-driven commonality analysis to streamline investigations, identify undetected escapes, and prevent recurrence. This combination strengthens confidence in product quality while protecting margins.

Lot Control and Traceability

yieldWerx also ensures comprehensive lot control and traceability by integrating seamlessly with other manufacturing tools. Engineers gain full visibility from wafers to packaged parts, ensuring consistent data flow across work centers. This end-to-end traceability not only supports operational efficiency but also reinforces compliance and quality assurance.

OEE to Advanced OEE Transformation

With these capabilities, yieldWerx provides a powerful platform to support Advanced OEE. Instead of acting as a lagging indicator of past performance, the yieldWerx framework becomes a real-time, predictive, and adaptive system. It predicts failures before they cause unplanned downtime, minimizes retests and wasted tester time, improves yield through advanced analytics, and maximizes the utilization of capital-intensive equipment.

By embedding advanced AI analytics and real-time monitoring into everyday workflows, yieldWerx ensures that fabs and OSATs can move confidently beyond OEE into a new era of equipment effectiveness.

Final Thoughts

Traditional OEE metrics have served manufacturers well for decades—but it’s no longer sufficient in the era of predictive analytics, AI/ML, and mass customization.

By moving beyond measurement to actionable, real-time optimization, Advanced OEE turns data into decisions that directly reduce downtime, improve yield, and maximize the ROI of capital-intensive equipment.

With solutions like yieldWerx’s Real-Time Machine Control & Monitoring module, the future of manufacturing efficiency isn’t just about tracking performance—it’s about predicting, adapting, and continuously improving.

The next generation of manufacturing efficiency is here.

The question is: are you ready to move beyond OEE?

Stop reacting. Start predicting. Advanced OEE with yieldWerx starts here.

Written by M. Rameez Arif, Content & Communication Specialist at yieldWerx.

Edited by Tina Shimizu, Content Strategist at yieldWerx.

FAQs

- What does OEE stand for?

OEE stands for Overall Equipment Effectiveness.

- Can OEE be more than 100%?

In some cases, you might see performance values reported above 100%, but this usually happens when the “ideal cycle time” is set incorrectly or too conservatively, making it appear as if the machine is outperforming expectations. In reality, OEE is always capped at 100%, which represents perfect production with no downtime, no slow cycles, and no defects.

- Who invented OEE?

The concept of Overall Equipment Effectiveness was first introduced in the 1982 Japanese book TPM Tenkai, published by the Japan Institute of Plant Maintenance and edited by Seiichi Nakajima. It later became widely known through its English translation, TPM Development Program – Implementing Total Productive Maintenance, released in 1989.

- What are OEE metrics?

OEE (Overall Equipment Effectiveness) is measured using three metrics:

- Availability – percentage of planned time the equipment is running.

- Performance – how close the equipment runs to its designed speed.

- Quality – percentage of good products out of total produced.

OEE = Availability × Performance × Quality.

- What are OEE systems?

OEE systems are software or digital platforms that track, calculate, and visualize OEE in real time.

- Is OEE a KPI?

Yes, OEE is a Key Performance Indicator (KPI) in manufacturing. It combines Availability, Performance, and Quality into one measure, helping track equipment efficiency, identify losses, and benchmark improvements across lines or plants.