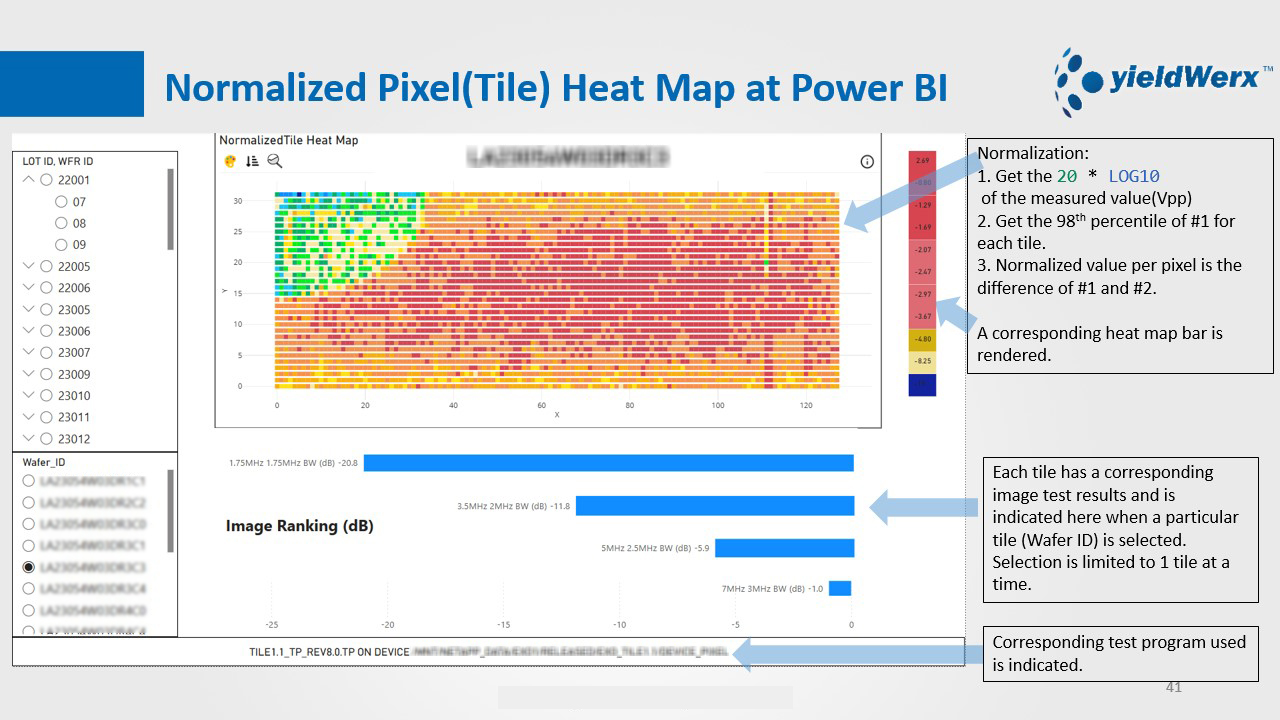

yieldWerx is an end-to-end data and yield-analytics platform purpose-built to manage extreme-scale semiconductor data with full lifecycle traceability. The platform ingests electrical and optical wafer acceptance data, pixel-level parametrics, coupon die measurements, ASIC parameters, assembly & module results, and final test outcomes.

yieldWerx enables combined analysis of ASIC + LED + image-sensor devices, including bonded wafers, in a single environment—delivering true system-level intelligence from discrete wafers to final modules.

The challenge is no longer collecting data — it is turning it into trusted intelligence that feeds AI, design, manufacturing, and field performance analytics. AI models rely on clean, trusted, high-granularity manufacturing data to unlock performance advantages such as:

Detecting depth, range, and gesture with absolute precision

As devices become smaller and more densely integrated, managing heat while minimizing power draw becomes increasingly critical

Discover the yieldWerx difference and revolutionize your semiconductor operations. Schedule a demo today!