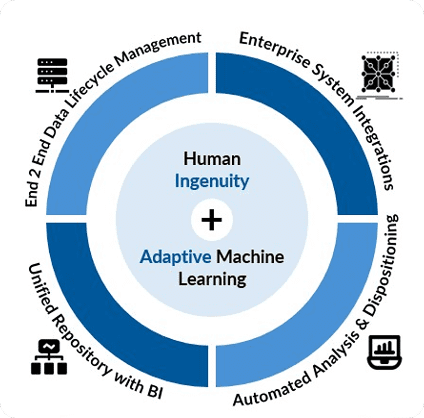

Our customizable product suite consists of 10 modules, some with their individual sub-modules, providing the ultimate flexible and scalable data analytics solution.

Holistic end-to-end data visualizations and insight

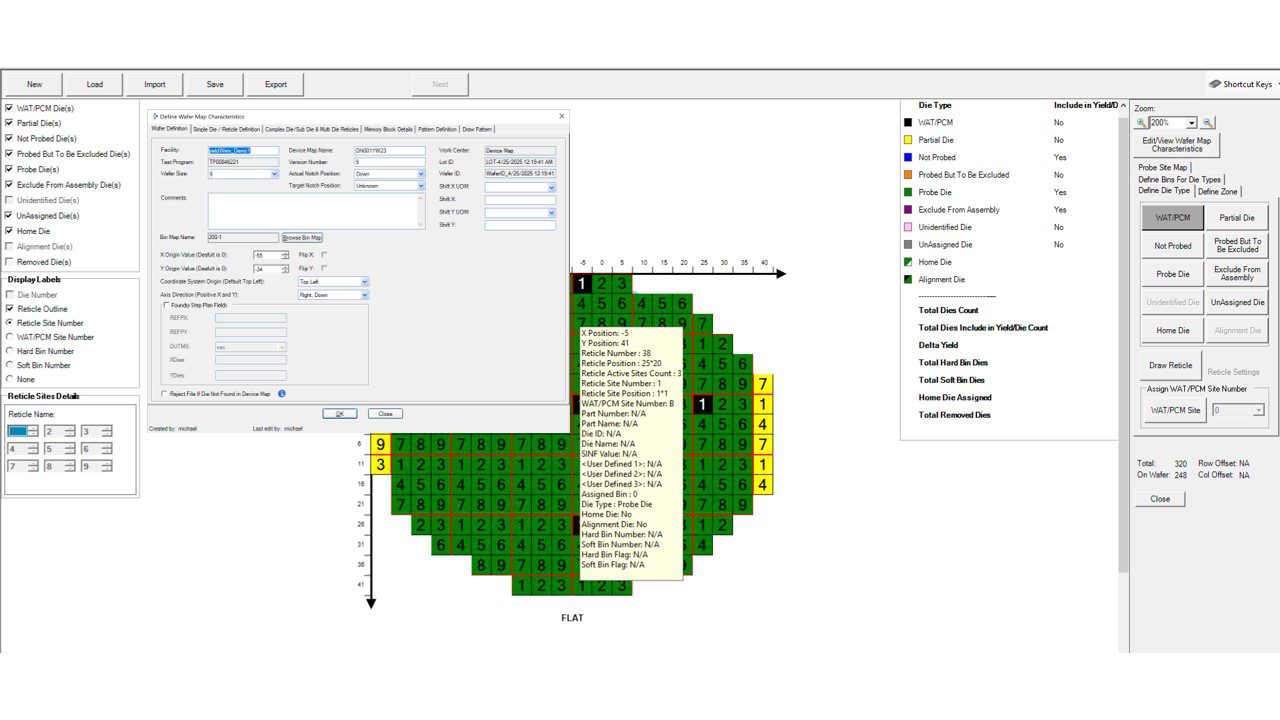

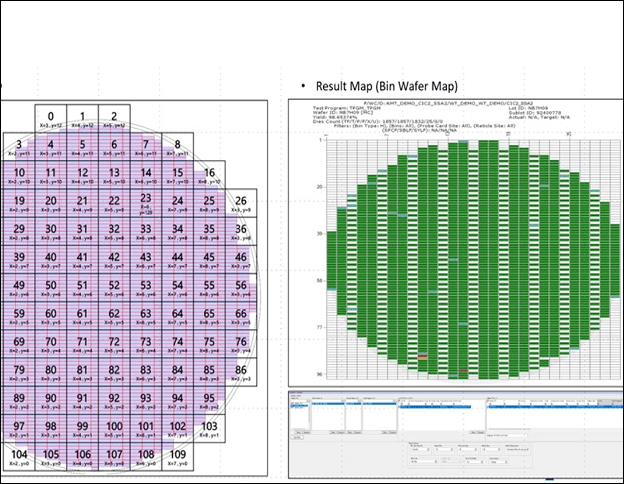

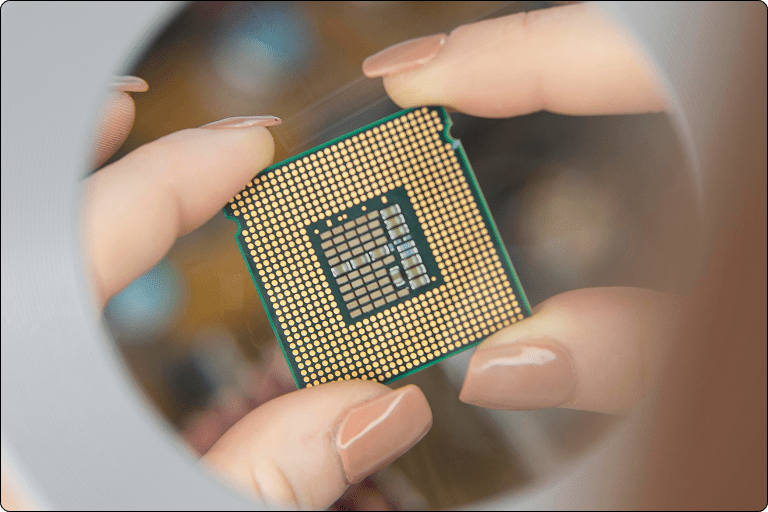

Advanced Product customizations for wafer, reticle, and die

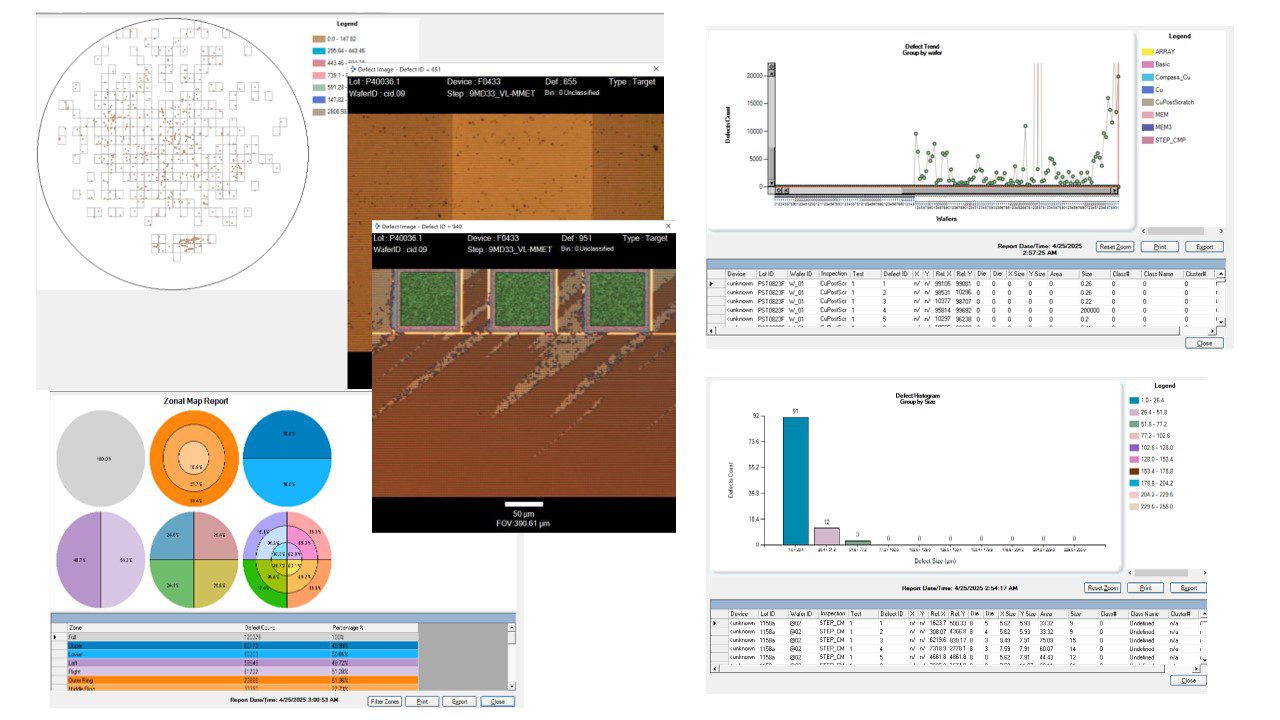

Management of the metrology, critical dimension, images, and defect data

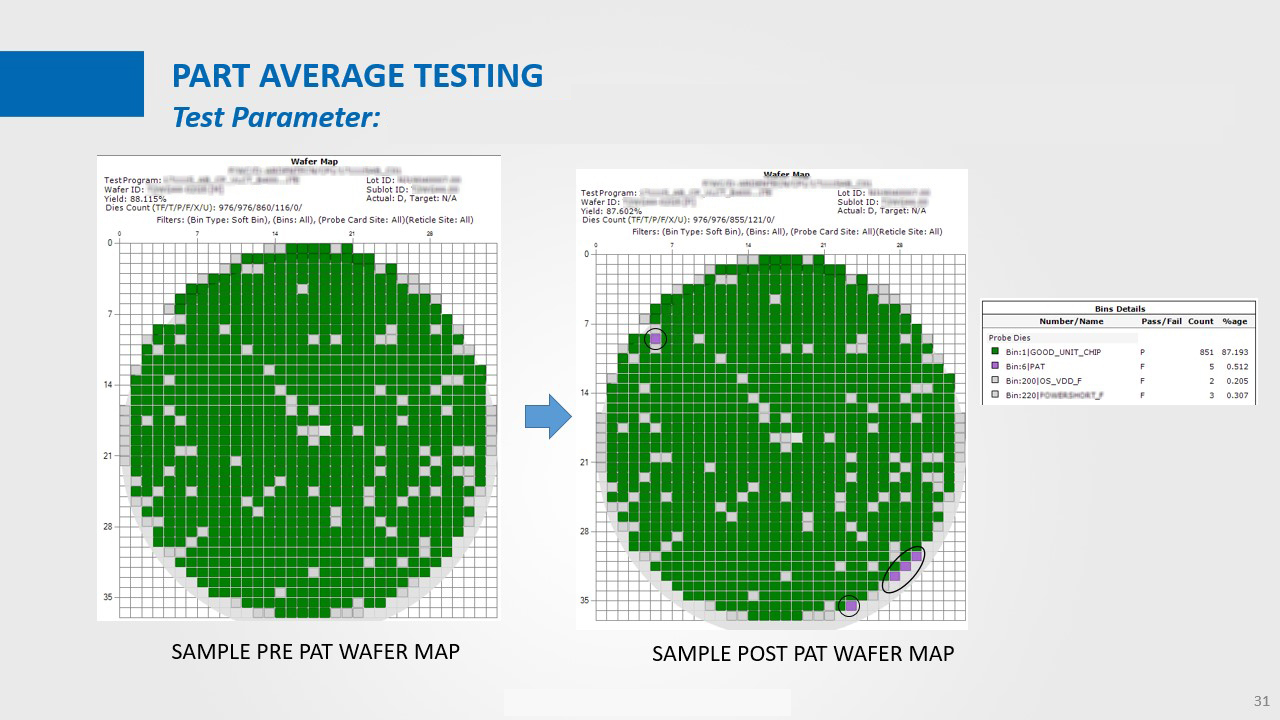

Robust outlier detection algorithms including PAT++, Zonal Pat, Nearest neighbor residual

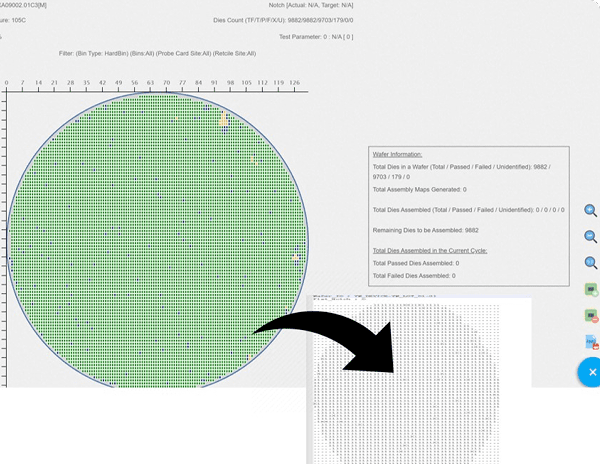

Ink and inkless wafer and reticle mapping allowing full control and seamless integration

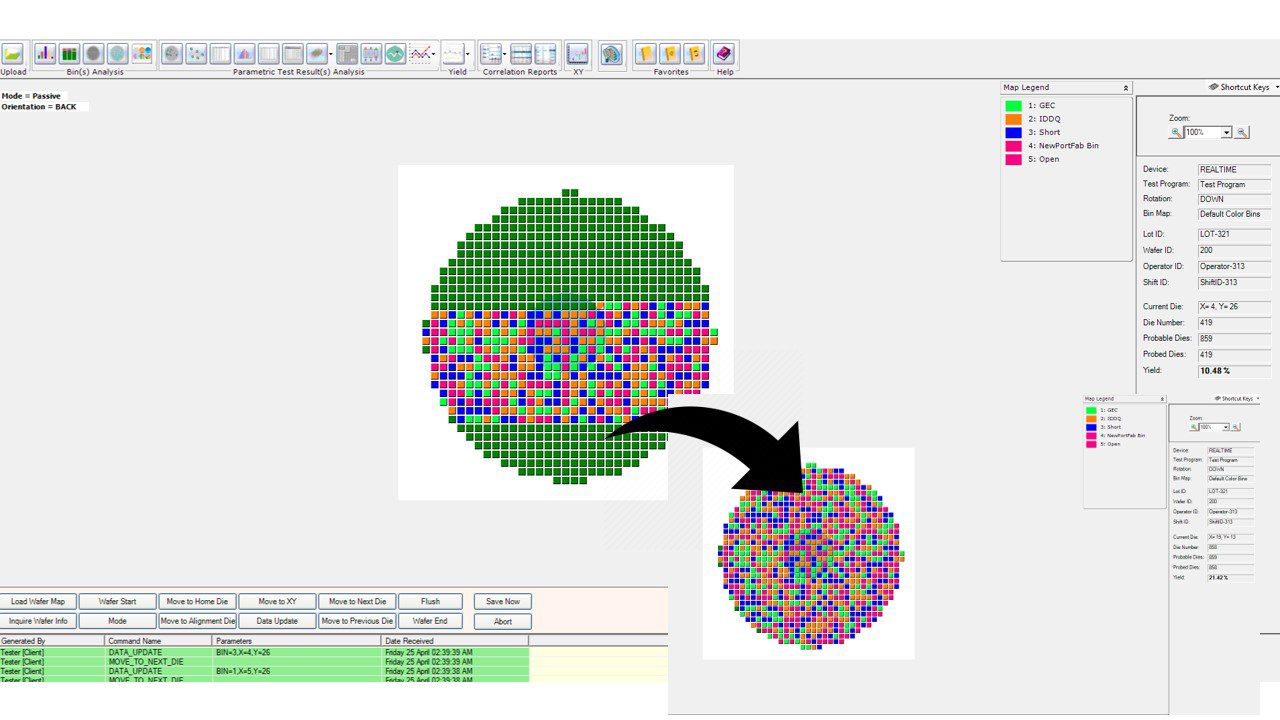

Real-time or passive data collection from equipment

Merges and redefines unique wafer and data sets, automating the merging process

Proactive real-time lot and wafer/screen management equipped with advanced AI

IP and Test parameter traceability that can track IP blocks and their specifications

Stringent test program release controls with version control of test program files

Aggregates data across product manufacturing lifecycle

Simple drag and drop features

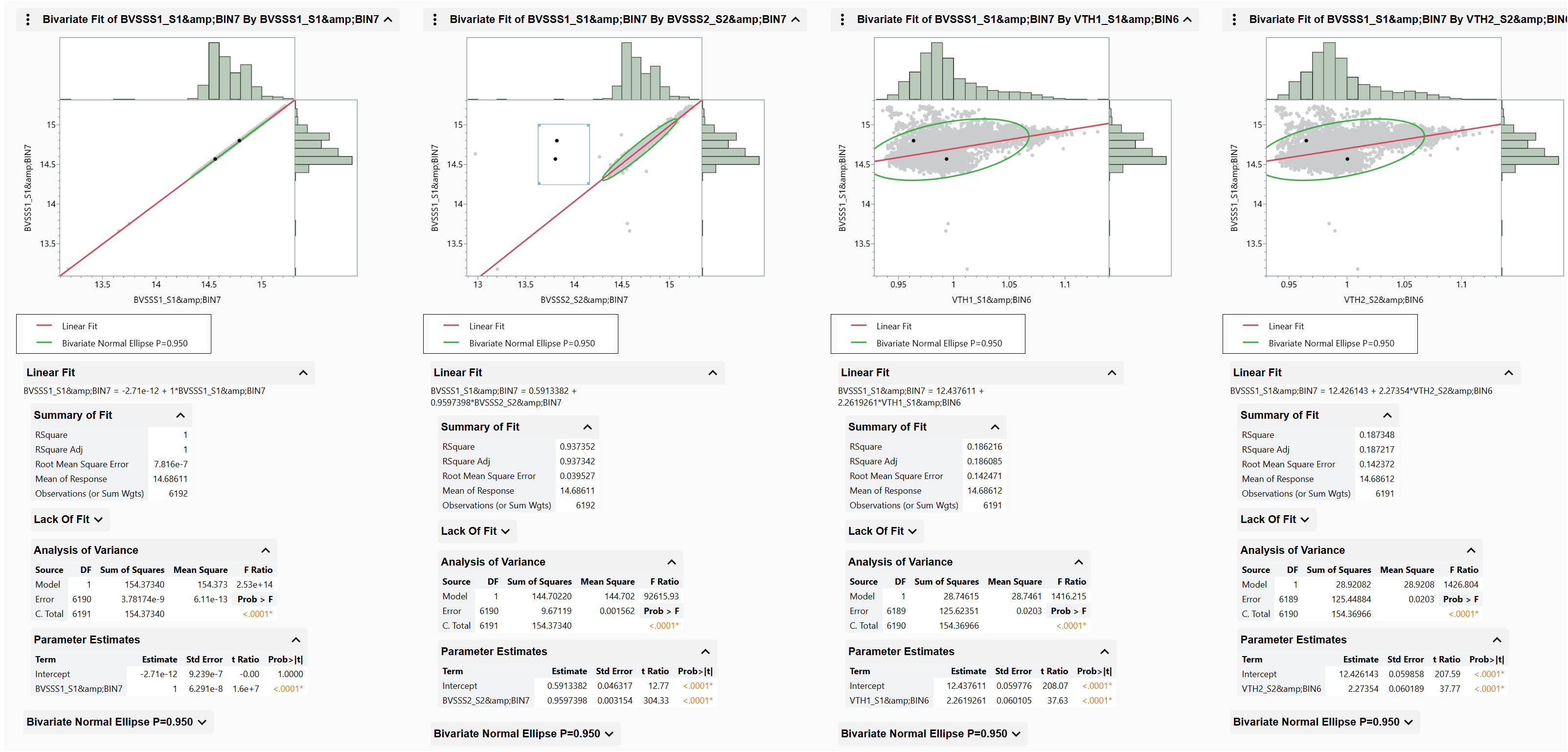

Extensive modeling and real-time analytics

Automatically set alerts and share reports

Allows for unique wafer probing edge and sequence definitions for characteristics, reticle, and device

Associates custom data to any data source and used in conjunction with realtime reports

Optimizes probing and inspection sequence/pattersns i.e. CCA

Maximize yield and attain zero defect certification

Dynamic and Static (SPAT and DPAT), Good Die in Bad Neighborhood (GDBN), GDBN-Z, Multivariant PAT, Non-Gaussian Data Distribution detection

Supports both ZPAT and NNR

Statistical process control (SPC), Statistical Bin Limit (SBL), Statistical Yield Limit (SYL)

Allows seamless application of unique policies and chracteristics to aggregated data

Enables comprehensive what-if analysis and generation of detailed assembly maps

Incorporate custom test points and defect information such as differing temperatures into aggregated data sets to predict issues before they occur

Real-time or passive data collection from equipment supporting parameter monitoring, DUT and generates adaptive probe wafer maps to minimize retest and touchdowns

Immediate insight into machine performance allows machine operators to quickly address downtimes and inefficiencies, reducing unnecessary downtimes and increasing throughput

Streamline Return Material Authorizations (RMA) for users utilizing Lot Genealogy alongside AI and ML learning for commonality analysis to identify undetected escapes and ascertain the impact on other lots

Using AI and ML learning, this module combines data from across the product test supply chain to forecast potential yield loss while guiding root cause analysis efforts

Automatically generate inkless assembly maps between prober and wafer test sites

Collection and analysis of serialized system and board data for traceability to packaged die across product lifecycle

Allows manual scrap or downgrade of die as well as pick die from wafer rather than complete wafer

Combnies test results from wafers, packaged die, and system boards for holistic view

Management of Critical Dimension (CD), Images and Defect Data

Facilitates rapid and previse root cause identification by linking defects to wafer probes, bin, sort, bitmap, parametric, and final test data

Efficiently identifies root causes and low yield causes

Enables analysis of significantly more and larger data sets quickly with assistance from AI/ML

In depth cross center correlation assisted by AI/ML algorithms through geospatial pattern recognition analysis of ANOVA

AI/ML knowledge graphs visually guide user down weighted paths to identify root causes

Provides Lot, Wafer, and Die level traceability from manufacturing to sort and final assembly

Tracks IP blocks to their specifications

Maintains consistent adherence to IP specs throughout manufacturing to ensure final product quality

Enables closed-loop processes for design to product yield enhancements and test time reduction (TTR)

Manages development and release of test programs, version control as well as files, vectors, and pattern files

Tracks engineering, qualification, and production releases to the relevant directories

Checks sums and enables release/push out releases internally as well as externally