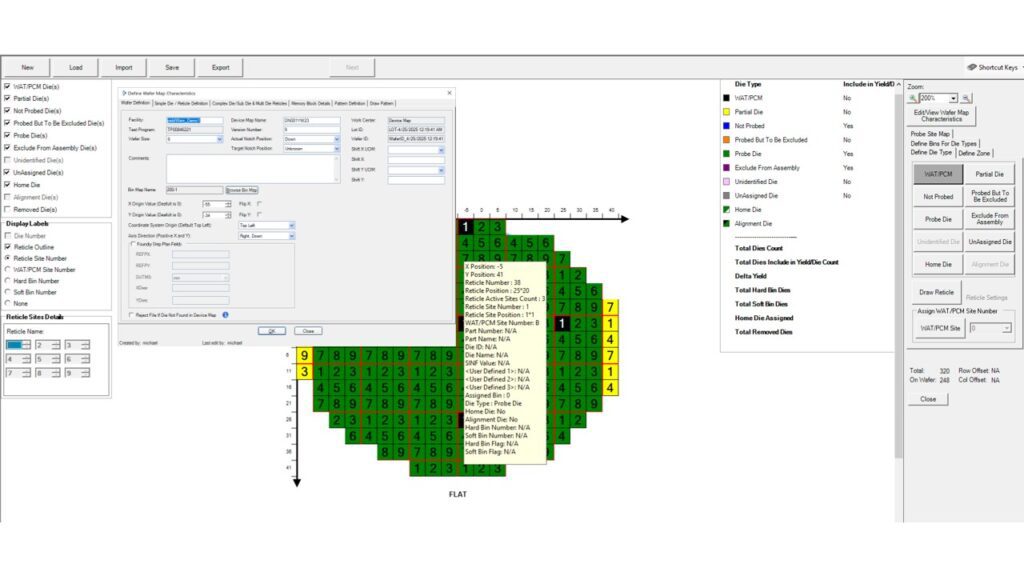

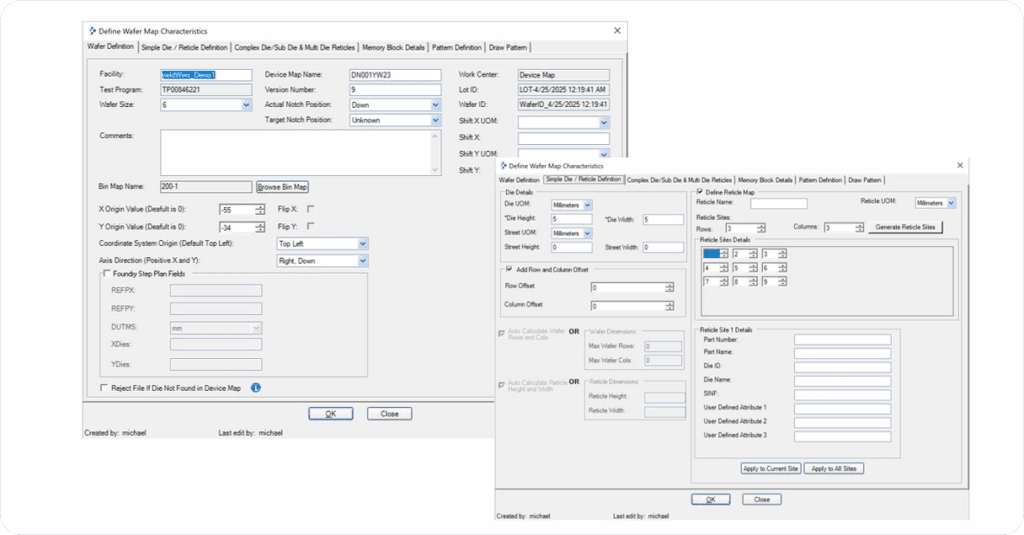

yieldWerx provides engineers with the ability to define wafer map setup, determining which dies to probe, not probe, assemble vs. unassemble, and many more. It allows engineers to mark edge dies, edge exclusion rings, probe sites, and reticle site information. yieldWerx supports multi-Project Wafers, where dies of different dimensions within a reticle shot can be defined. Advanced parameters, including Zones, can be defined and logic applied. This information can then be used to drive and control test equipment, such as optimized probing or inspection sequences/patterns (i.e., CCA – Critical Care Areas). This functionality becomes a more powerful quality improvement tool, allowing engineers to minimize the number of touchdowns made on dies. The Product/Device Setup information can be used in real-time reports and analysis, for data enrichment, or a combination of the two. The yieldWerx Product/Device Setup module also provides a unique capability for Design and Product Engineers to collaborate – GDSII to Test & Yield Management (The GDSII format supports hierarchical designs, enabling designers to create complex layouts efficiently by reusing smaller blocks.)