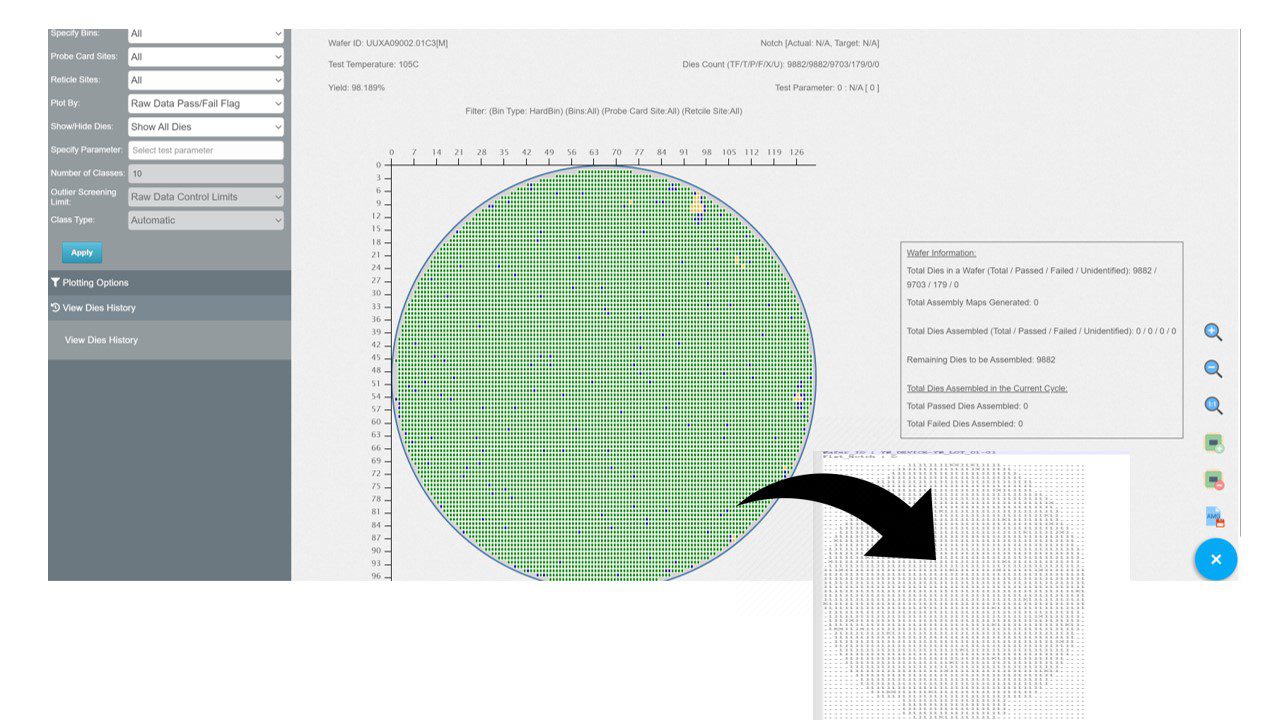

Optimize wafer test efficiency with full control and seamless integration between prober and wafer test sites, enabling testing, inking functions, and the identification of unique probing sequences for wafer and reticle sites. Equipped with AMG capabilities, Package and Board Management features, as well as Wafer bank grading.

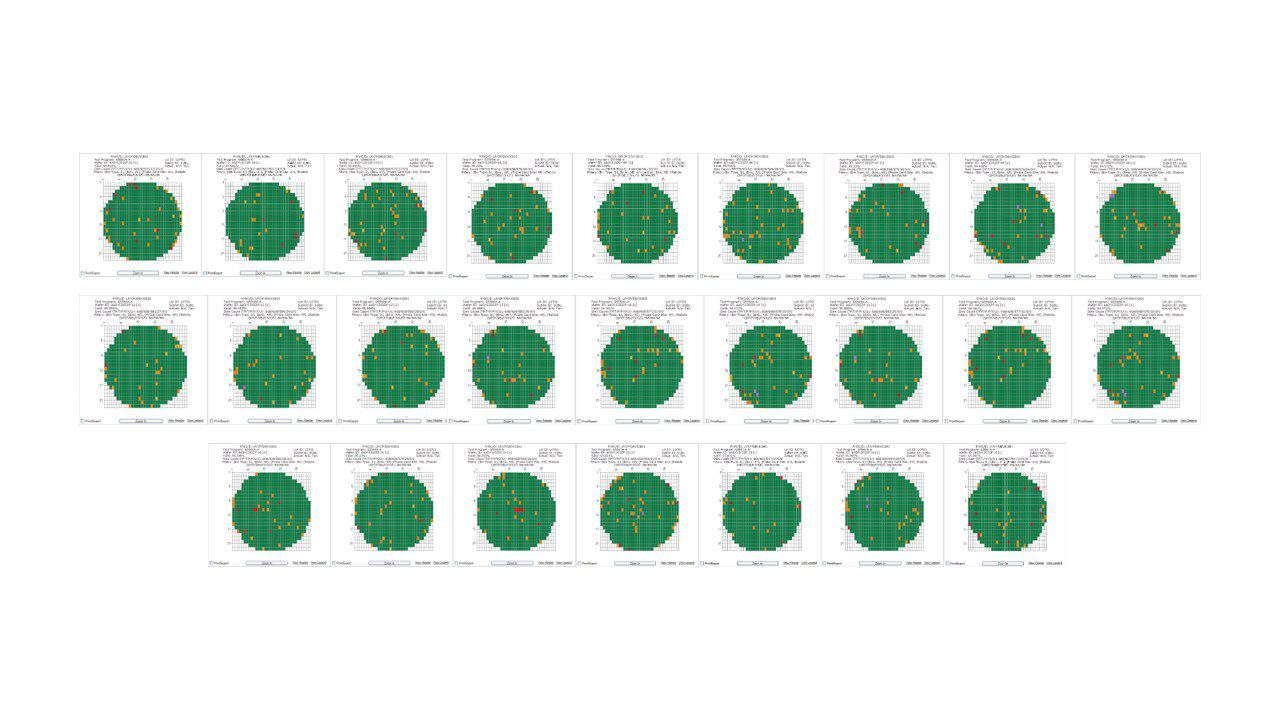

yieldWerx provides the capability to automatically generate Inkless Assembly Maps, also known as Ink Maps, for instances where physical inking may be necessary. The platform allows for the seamless merging of Assembly Maps with additional data, enhancing analysis and enrichment. It also supports the manual generation of assembly maps, die downgrading, and scrapping, as well as managing Die and Wafer Banks, ensuring comprehensive functionality for test and yield analysis.

yieldWerx offers the functionality to manually scrap or downgrade die, as well as selectively pick dies from wafers, enabling tracking to specific assembly lots rather than selecting an entire wafer. This capability is particularly beneficial for low-volume applications in the Aerospace and Defense sectors. Users can ‘Re-bin’ die according to custom limits or other business rules defined based on the data collected throughout the wafer’s genealogy. Each ‘Picked Map’ is systematically saved within yieldWerx to facilitate historical reference and audit compliance.

yieldWerx enables the collection and analysis of Serialized System and Board data, ensuring traceability from the System and Board level to the Packaged Die and throughout the entire product lifecycle. This integrated tool streamlines the testing process by allowing engineers and quality assurance teams to evaluate data across various production stages simultaneously to identify correlations that may impact yield.