Rapid Characterization and R&R

Robust Characterization and Gage R&R reports

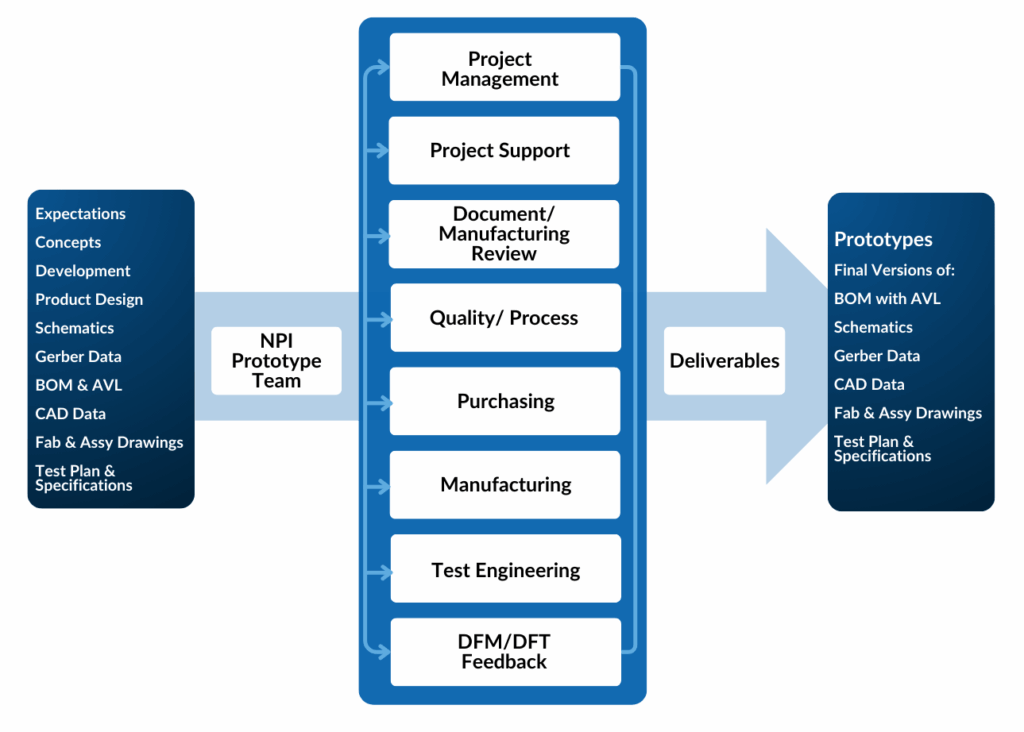

Accelerate your time to market for New Product Introduction with rapid characterization reports, Gage R&R, split lot analysis, drift analysis and identify design sensitivities early and prevent costly re-spins.

During the New Product Introduction stage of a product, time is paramount. Designs need to be quickly and thoroughly validated to prevent yield loss and inconsistencies.

From collecting data across a broad range of systems and sources to cross correlation analytics and making sense of the data points via reports visualizations, yieldWerx provides an unparalleled advantage.

Discover the yieldwWerx difference and revolutionize your semiconductor operations. Schedule a demo today!