wafer and die

wafer and die

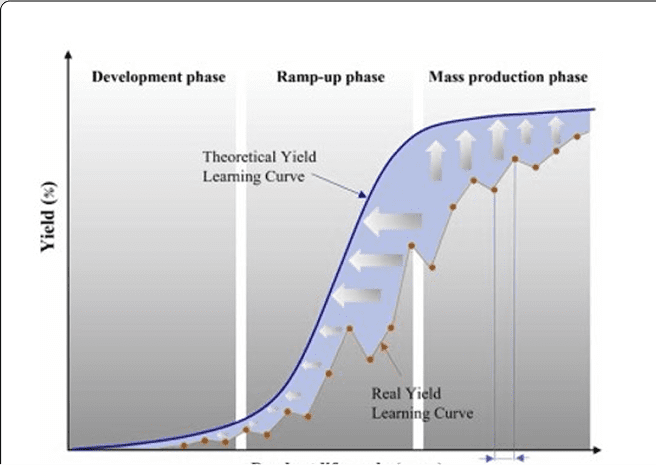

yieldWerx helps maximize high-volume manufacturing performance for stability and consistency in advanced production stages.

The full-scale, high-volume production stage of a product requires intense focus on maximizing production efficiency, maintaining high-yields, meeting customer demands for volume and quality, while also reducing costs.

yieldWerx ensures products that are in Mass or Advanced Production maintain high yields despite high-volumes with advanced statistical controls, outlier protection, and AI-assisted commonality assessments that can send real-time alerts to prompt for corrective action. This ensures process stability and enables active yield-monitoring across global supply chains.

Discover the yieldwWerx difference and revolutionize your semiconductor operations. Schedule a demo today!