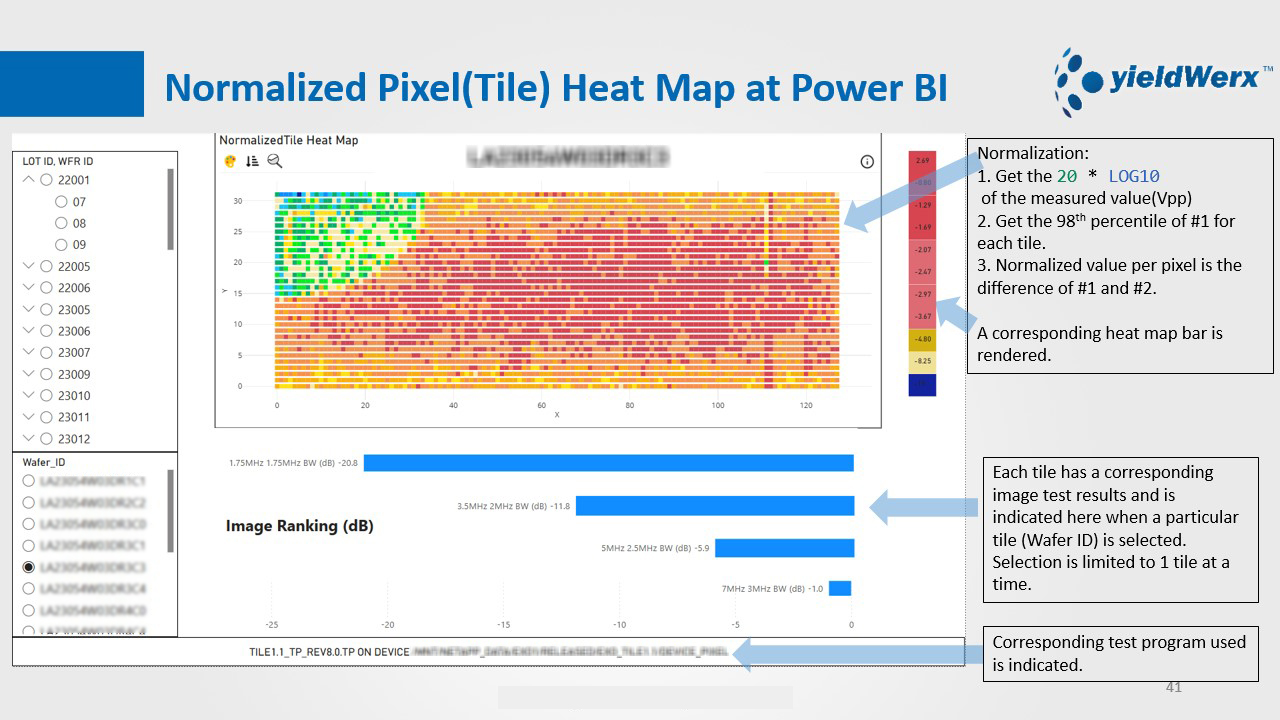

yieldWerx serves as the enterprise platform for high-quality photonics manufacturing data, spanning wafer probe, optical wafer acceptance test (OWAT), electrical wafer acceptance test (EWAT), module and device assembly, burn-in, and final system test. The platform manages raw data and produces enriched, post-processed results including PAT, virtual binning using custom optical/electrical limits, GDBN/GDBN-Z, multisite merging, multi-insertion merging, and automated pick-map generation. These analytics-ready outputs become the foundation for Design of Experiments (DoEs), parametric optimization, and custom analytics pipelines in photonics manufacturing and optical I/O.

As photonics moves from R&D to high-volume manufacturing, the challenge is no longer generating data — it is turning highly heterogeneous photonic, optical, and electrical test data into clean, contextualized information that teams can trust. yieldWerx enables this shift by providing a unified data model, automated enrichment, and analytics that operate across wafers, modules, systems, and field-return data. This is exactly where yieldWerx is helping leading photonics companies today.

Multiple test domains, formats, and vendors create fragmentation that prevents rapid, confident decision making.

Siloed systems obscure traceability from wafer probe through assembly and final verification, slowing yield learning and root-cause analysis.

Manual scripts and one-off analyses cannot keep pace with high-volume photonics manufacturing and evolving device architectures.

A leading U.S. photonics company selected yieldWerx for its ability to rapidly deploy a true end-to-end solution. In just 30 days, yieldWerx ingested heterogeneous photonics data sources, implemented wafer-to-module-to-system traceability, enabled automated PAT/GDBN workflows, and delivered production-ready dashboards and DOE-ready datasets. The decision was driven by our configurable platform, speed-to-value execution model, and deep domain expertise in photonics and optical I/O manufacturing.

YieldWerx offers free webinars and downloadable resources covering functionality, data formats and standards, lessons learned, and best practices to elevate your photonics solutions. Sign up below to access these materials and build the foundation to scale your innovation.