Outsourced Semiconductor Assembly & Test (OSAT) providers support Fabless companies, IDMs, and foundries. Their challenges grow as they manage a diverse portfolio of products for various customers, all while maximizing the return on their CapEx investments in facilities, manufacturing, assembly, and test equipment. Overall Equipment Efficiency (OEE) and maximizing operational efficiency are key objectives for OSAT management.

Become an industry leader by maximizing yield and quality with yieldWerx’s advanced analytics. Our solution enables you to be flexible and adaptable to your customers, allowing clean, real-time data to flow seamlessly and securely throughout your manufacturing supply chain.

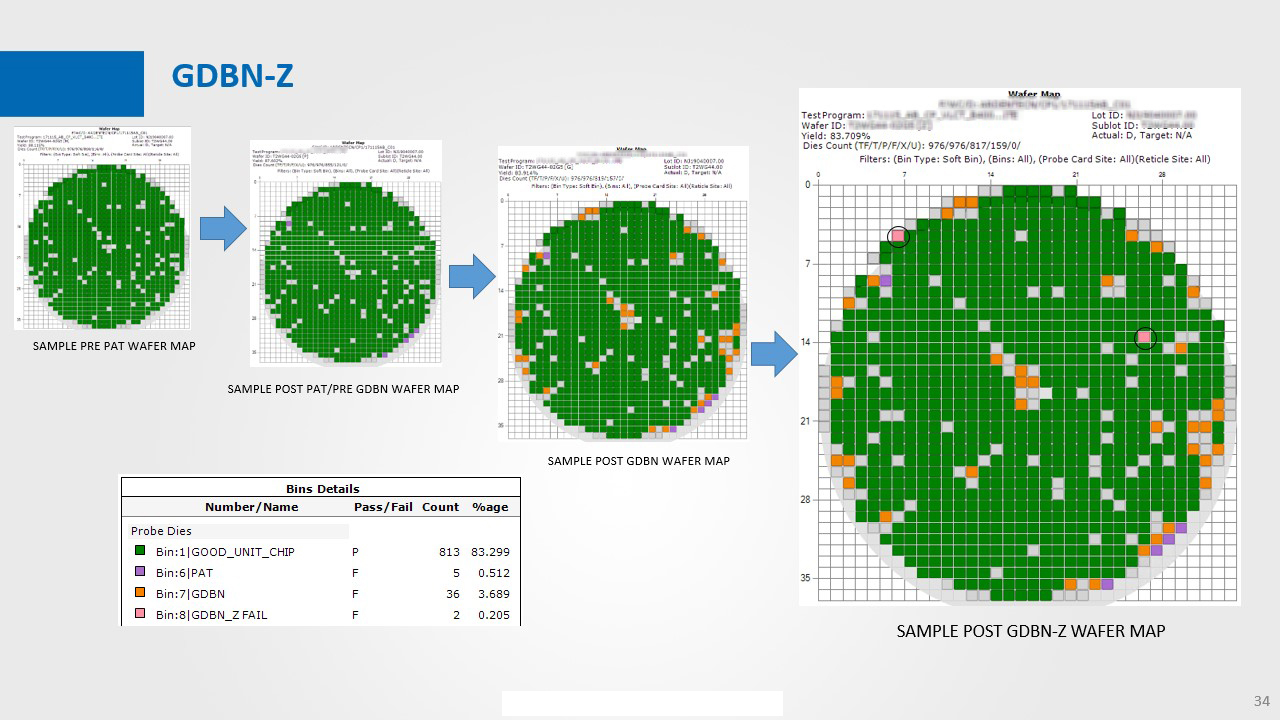

Access real-time metrics for yield performance and utilize advanced parameter customizations to address quality issues, providing OSAT customers with the ability to access near-real-time yield and test-related reports and analysis. This enables customers to make adjustments in test program releases, limits management, and more. yieldWerx also helps OSAT’s customers enter the automotive sector by offering quality modules such as Part Average Test (SPAT, DPAT) in real time, as well as post-test, Good Die in a Bad Neighborhood (GDBN), and many others.

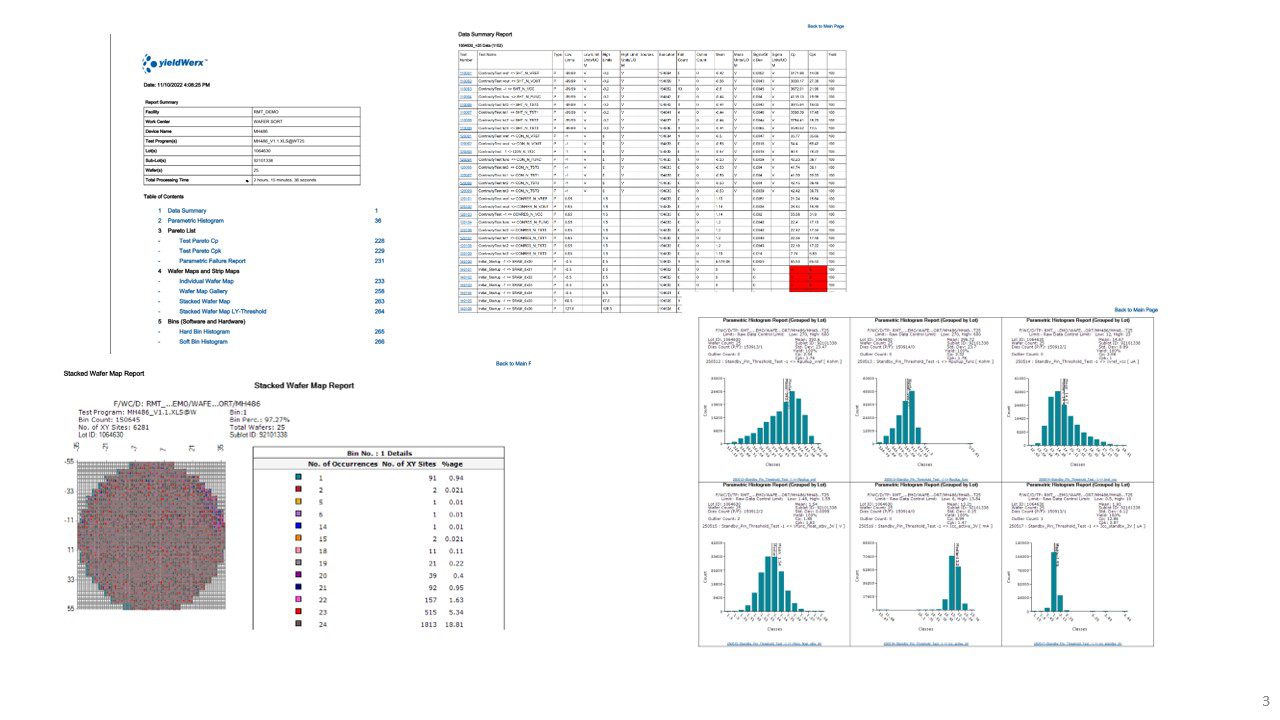

Access yield and test related reports real time to take preventative actions

Quality control modules such as Part Average Tests (SPAT, DPAT) in real time

Comprehensive Limits management including GDBN and more

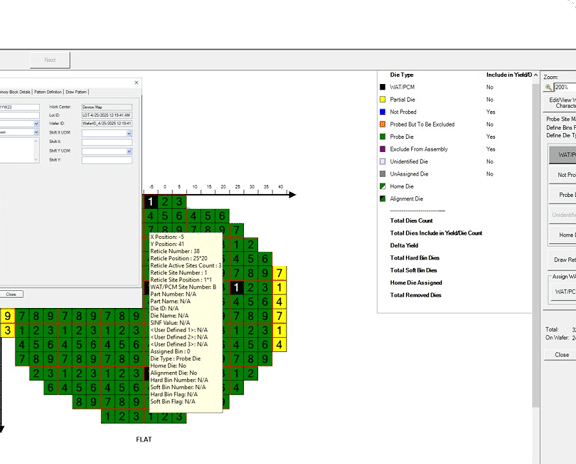

Data consistency and alignment collected from test, assembly, and packaging allow OSATs to easily compare environments and drill down to identify deviations. This also enables OSATs to quickly bring new customers and products into production and helps customers identify yield issues.

Easily compare environments to identify deviations

Test Program/Recipe Management facilitates advanced process controls for continuous yield monitoring

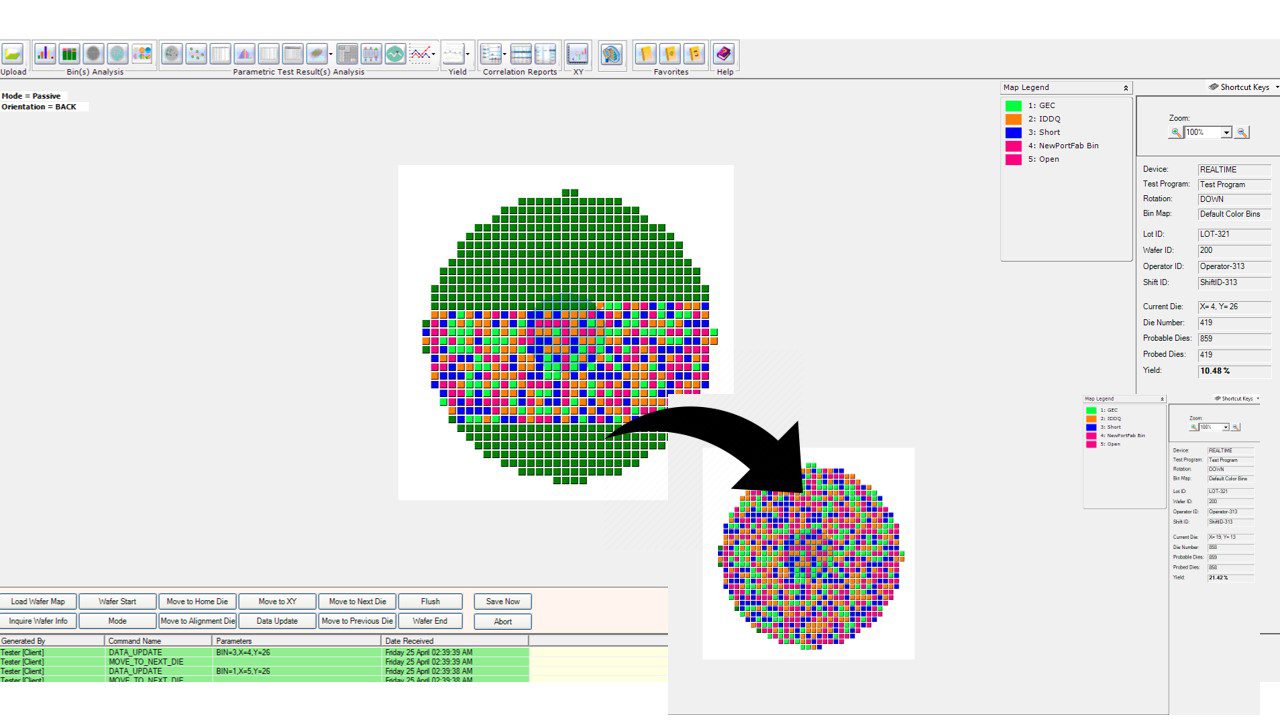

Real Time Machine Control enables real-time monitoring of equipment such as testers, handler, probe cards, and load boards

yieldWerx provides full automation for the OSAT to configure in conjunction with the customer. Materials are assembled and tested following standard SOPs, and data, along with standard reports, are then fed to customers from yieldWerx.

Full automations for OSAT and customers collaborations

Enables materials to flow through different assembly test routes with minimal changes

Allows for HW calibrations and diagnostic data analysis

The OSAT is able to access real-time yield test data and OEE reports for quick feedback loops, health monitoring, and timely interventions. The customer, on the other hand, can access standard reports in real time, conduct their own realtime analysis, and collaborate with the OSAT on test program changes, test limits management, and more.

Real time test data and OEE Reports for quick feedback loops

Enables real-time test monitoring and timely interventions

Over 300 predefined reports or create self-service reporting for your end customer

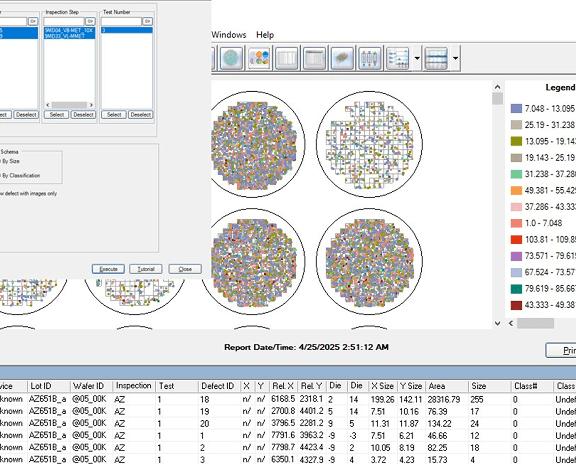

With yieldWerx’s AI/ML-assisted defect detection and rapid

drill-down root cause knowledge graphs, IDMs can easily sift through millions or billions of data points to pinpoint root causes quickly and accurately. This enables faster decision-making to interdict Assembly and Test processes. yieldWerx also supports Feed Forward and Feedback Closed Loops, which can change manufacturing recipes, probing patterns, test programs, or test limits—collaborating with both Foundries/IDMs and Design Houses.

Defect Management uses image guided correlation analysis to find defects quickly and accurately

Easily sift through billions of data points to identify root causes for faster decision-making

Supports Feed Forward and Feedback Closed loops enabling changes to recipes and probing patterns

Discover the yieldWerx difference and revolutionize your semiconductor operations. Schedule a demo today!