yieldWerx allows foundries to analyze test data for their own Test Vehicles and Test Chips, enabling them to qualify their TDKs. Additionally, we partner with all major foundries to

interpret and load the WAT/PCM and any other data types they provide to their customers.

Our powerful data analytics solution enables full integration between foundries, their partners, and their customers, providing complete traceability that reduces waste and minimizes retests.

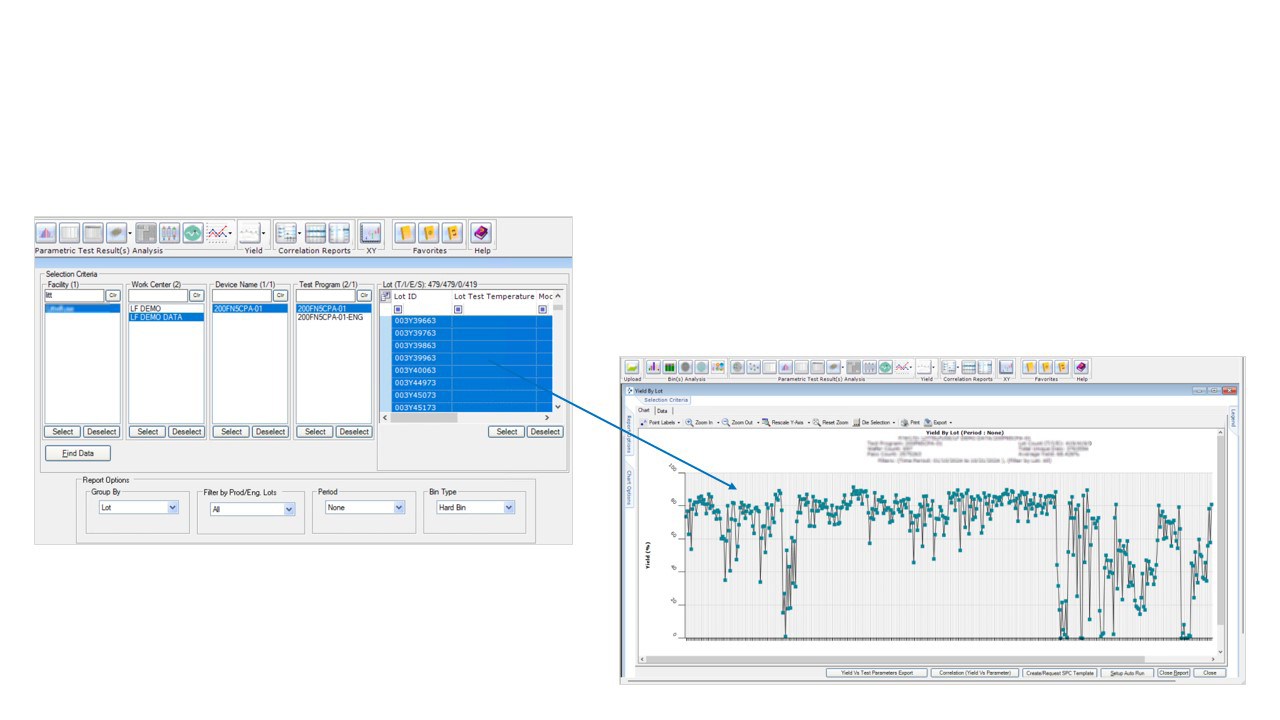

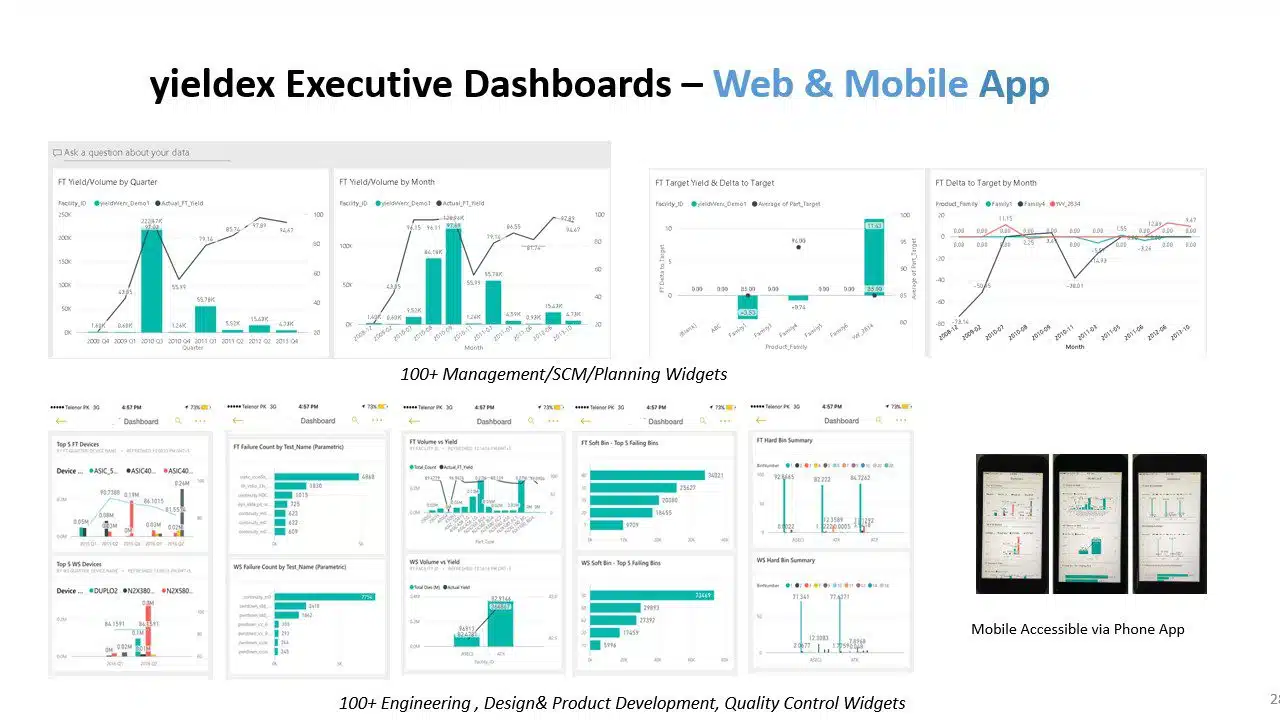

Foundries can access real-time process and yield test data, as well as health monitoring for quick feedback loops and timely interventions. This includes the ability to monitor lots and equipment on Engineering or Manufacturing Holds. yieldWerx enables interaction with Process and Test/Assembly equipment—allowing for passive monitoring, intervention, or full control of the equipment. It also integrates with enterprise-wide systems like MES (Manufacturing Execution Systems), QMS (Quality Management Systems), and AMS (Asset Management Systems), offering deeply integrated solutions and functionality.

Real time test data and OEE Reports for quick feedback loops

Enables real-time test monitoring and timely interventions

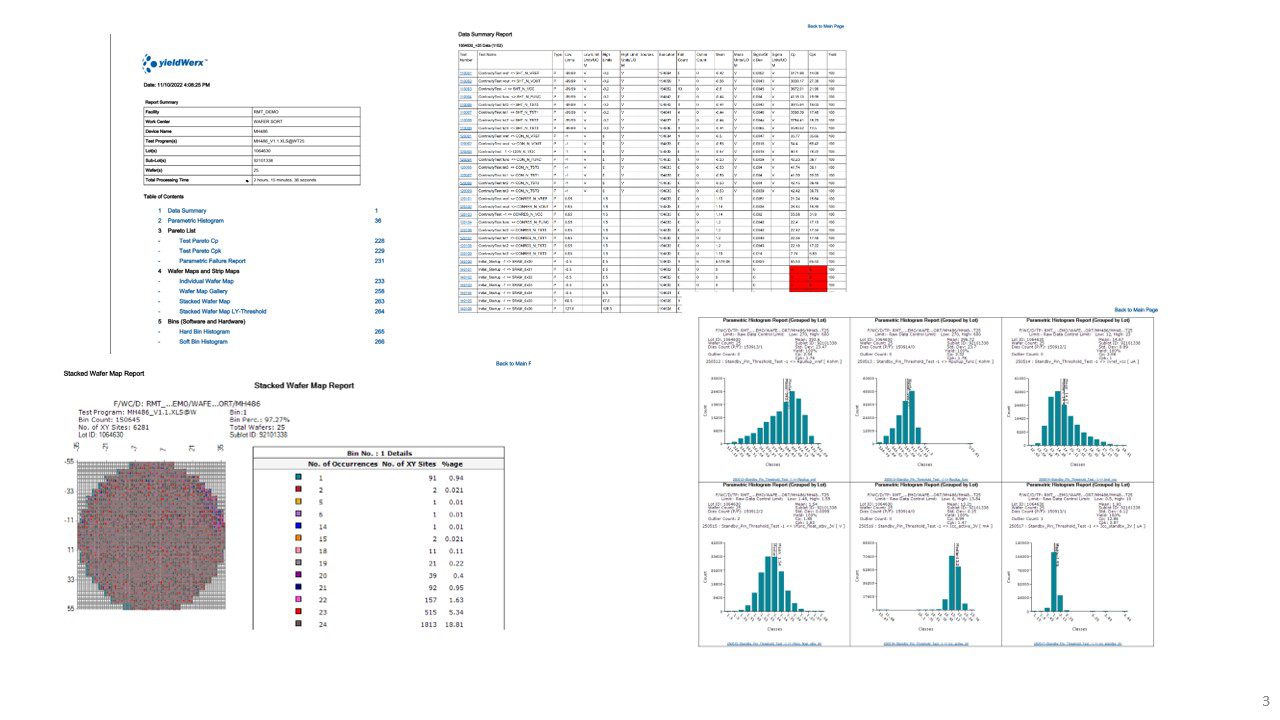

Over 300 predefined reports or create self-service reporting for your end customer

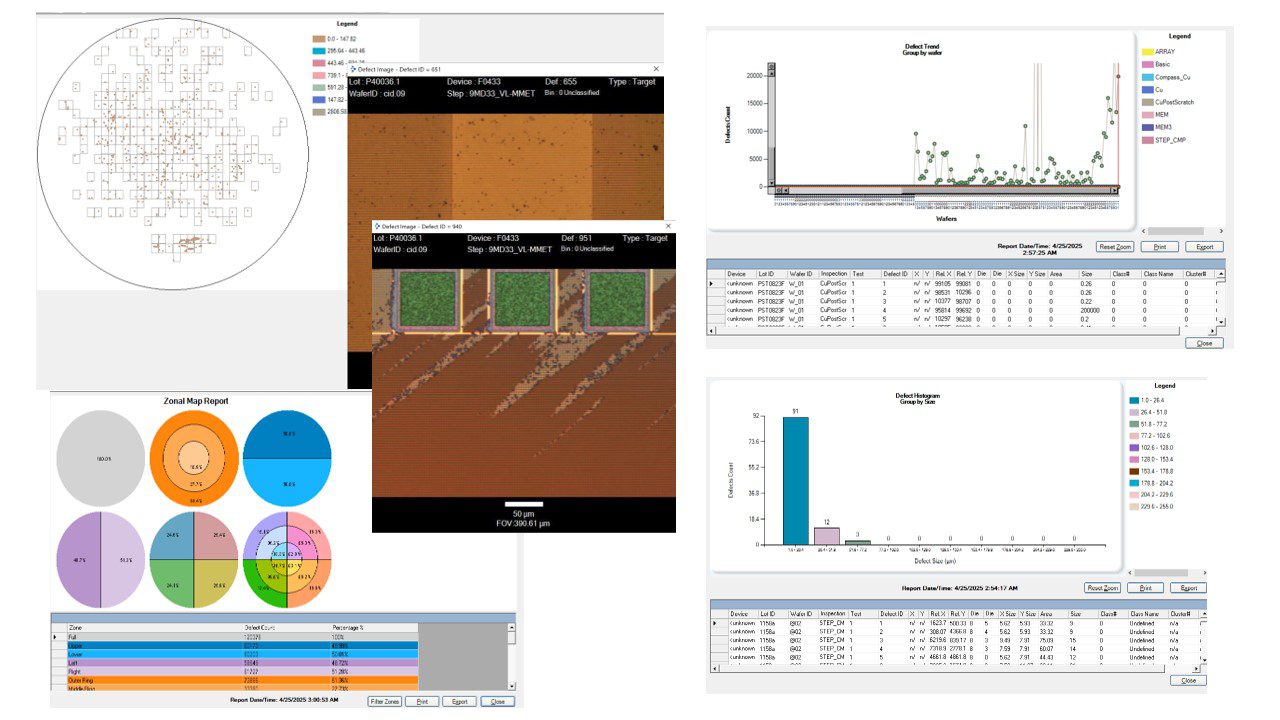

With yieldWerx’s AI/ML-assisted defect detection and rapid drill-down root cause knowledge graphs, Foundries can easily sift through millions or billions of data points to pinpoint root causes quickly and accurately. This enables faster decision-making to interdict manufacturing processes and equipment. yieldWerx also supports Feed Forward and Feedback Closed Loops, which can change manufacturing recipes, probing patterns, test programs, or test limits, to name a few.

Root Cause Knowledge Graphs enable rapid AI-assisted defect analysis

Defect Management uses image guided correlation analysis to find defects quickly and accurately

Supports Feed Forward and Feedback Closed Loops

With yieldWerx’s AI-assisted predictive analytics, foundries can proactively identify process variations through pattern recognition and advanced statistical algorithms, detecting potential yield loss before manufacturing begins and throughout the manufacturing process. This also enables foundries to receive feedback from customers based on their yield test and analysis at either probe or final test, allowing them to adjust process parameters if needed.

Yield Prediction enhances forecasting accuracy for escape prevention

AI Powered Commonality Analysis isolates systemic causes of yield loss

yieldWerx can manage large volumes of production data through our scalable infrastructure. Our data storage and modules are designed to handle gigabytes/terabytes of data daily, with large-scale databases in the order of petabytes. yieldWerx also supports multiple databases to handle Engineering, Characterization, and Production data. Additionally, yieldWerx offers Data Warehousing solutions that ingest data from various sources, providing a one-stop shop for data and yield analysis across a much

richer data set.

Manage large volumes (up to petabytes) of data securely through a scalable infrastructure

Architecture that supports multiple databases to handle Engineering, Characterization, and Production data

Data warehousing solutions that can ingest data from multiple sources

Discover the yieldWerx difference and revolutionize your semiconductor operations. Schedule a demo today!