yieldWerx allows Equipment Manufacturers to tightly integrate with their equipment, providing deeper control, real-time monitoring, and interdiction. By monitoring operational aspects such as OEE, calibration and qualification data, setup data, etc., yieldWerx helps improve product quality and enhance equipment uptime and reliability.

Post-Moore’s Law, innovation no longer hinges on shrinking transistors; instead, semiconductor equipment manufacturers must stay competitive through advanced analytics and AI-driven insights. Our solution enables them to stay ahead of the curve by focusing on real-time process management, clean yield, and advanced automation.

yieldWerx’s modular solutions provide equipment manufacturers with the ability to tailor their process flows and operational aspects more precisely and deeply within yieldWerx. Additionally, yieldWerx can monitor fleets of equipment, both onsite and in remote deployments.

Manage large volumes (up to petabytes) of data securely through a scalable infrastructure

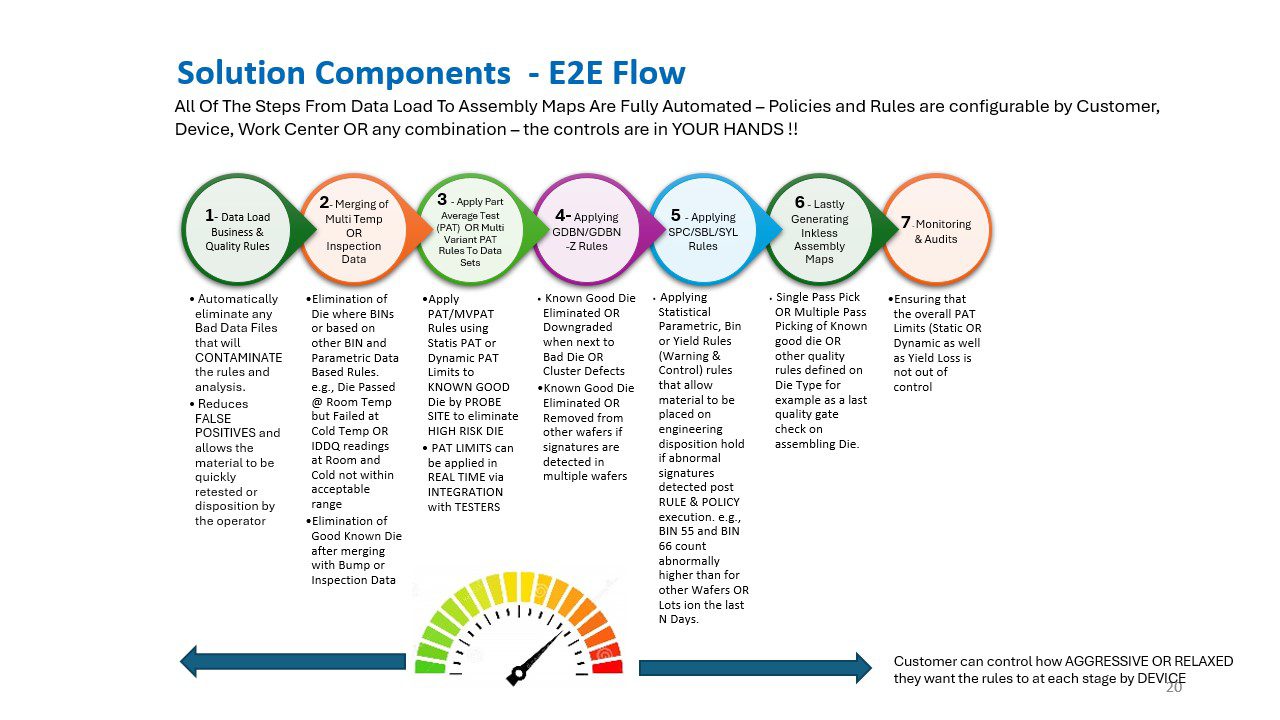

Tailor process flows and operational aspects more precisely

Monitor fleets of equipment onsite or remotely

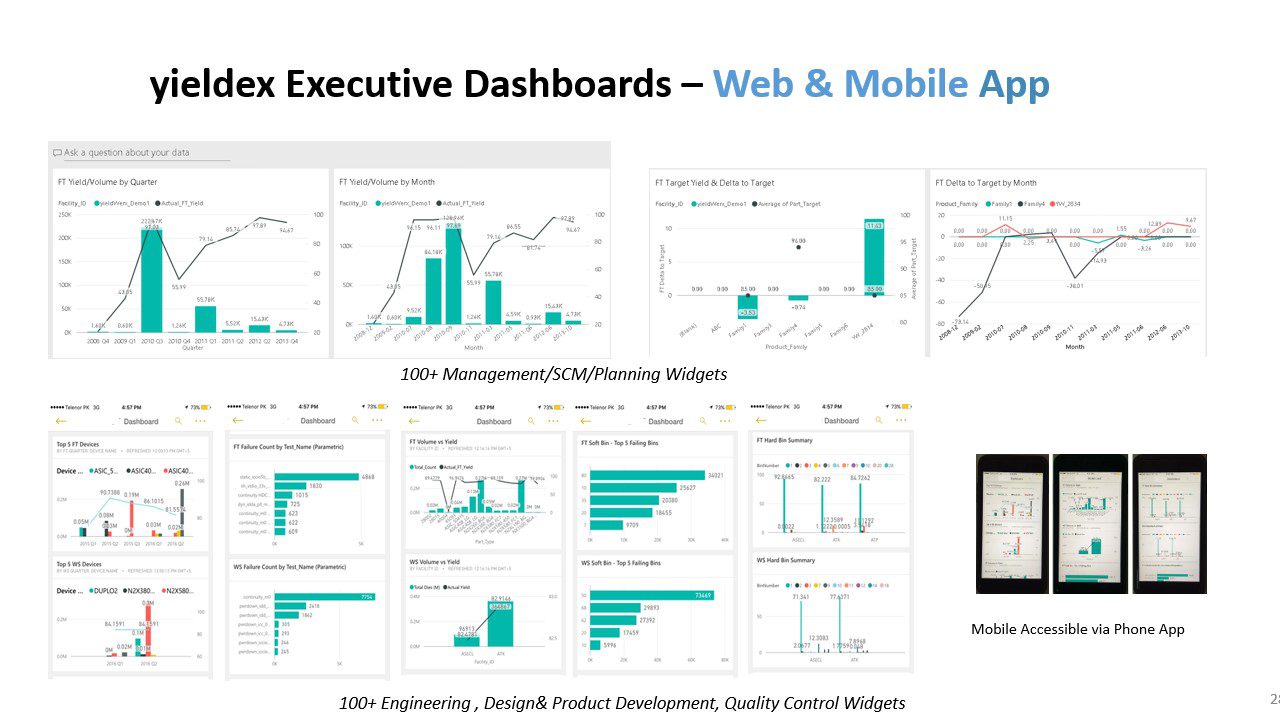

Equipment manufacturers can access hundreds of ready-to-use widgets through our powerful BI interface, build data marts with external sources using simple drag-and-drop, and perform extensive modeling and real-time analytics.

Powerful BI offering hundreds of ready-to-use widgets

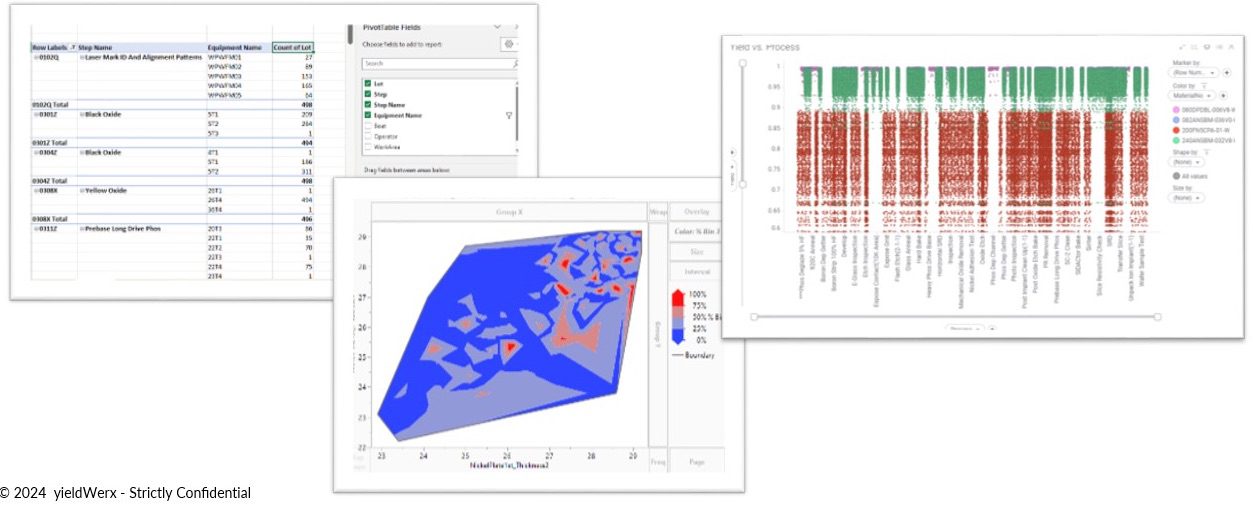

Build data marts with external sources using simple drag-and-drop

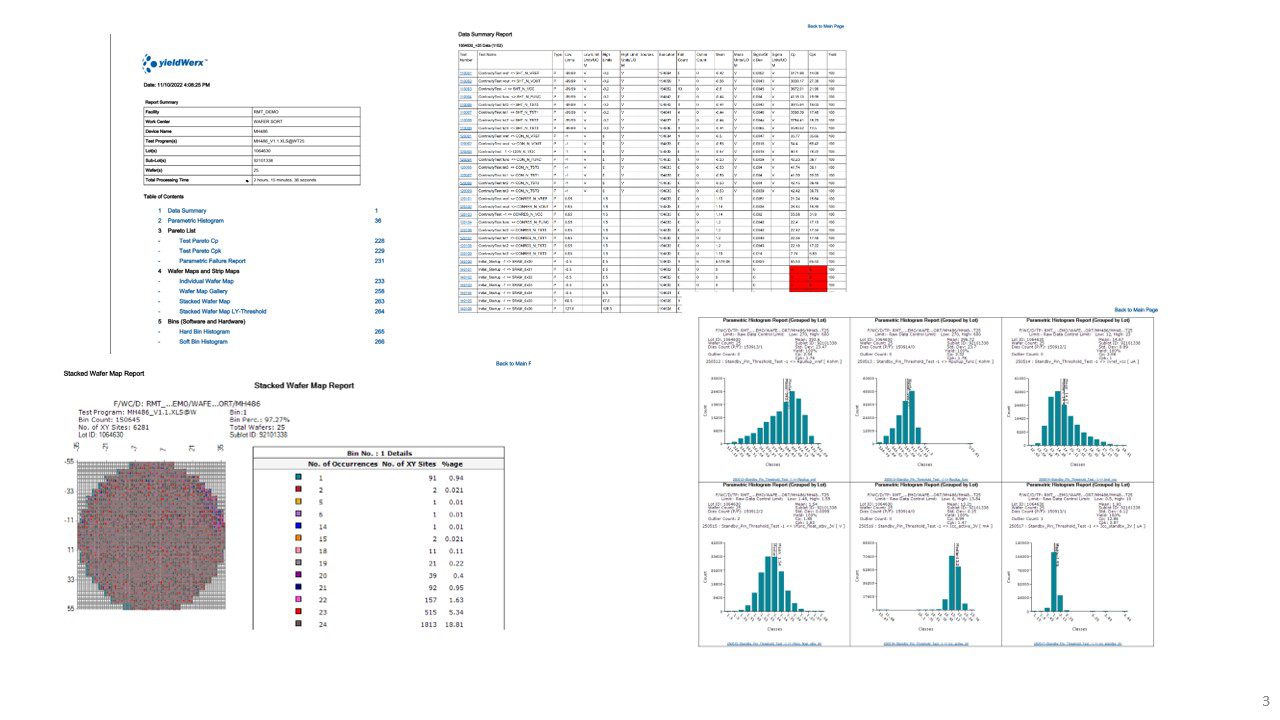

Perform extensive modeling and real-time analytics

Coupled with yieldWerx’s AI/ML capabilities, equipment manufacturers can predict when preventative maintenance will be needed, when failures are likely to occur, and when elements of the equipment or its configuration are causing or contributing to test failures or producing outliers.

Defect Management uses image guided correlation analysis to find defects quickly and accurately

Inspection Image Maps connects inspection data to actual images for data correlation

Root Cause Knowledge Graphs enable rapid AI-assisted defect analysis

Equipment manufacturers can leverage yieldWerx’s process automation to diagnose and alert equipment failures in real time, alleviating the need for manual engineering oversight. yieldWerx can monitor equipment sensor data, OEE, equipment calibration, and diagnostic data.

Diagnose and notify on equipment failures early

Alleviate manual intervention and oversight

Keep a pulse on OEE and calibration and diagnostic data

Discover the yieldWerx difference and revolutionize your semiconductor operations. Schedule a demo today!