Memory technologies such as DRAM and NAND Flash are critical components in digital devices, shaping the functionality and performance of everything from smartphones to servers. Manufacturing these technologies is highly complex, making yield management an essential aspect. Yield management involves carefully monitoring and optimizing each step of the chip production process to maximize the output of functional units.

Advanced yield management takes this concept further by employing strategies and technologies to address the unique challenges of memory chip production. It integrates process control, quality assurance, fault diagnosis, and data analysis to improve yield rates significantly.

The Significance of Yield Optimization in Memory Technologies

Yield optimization is essential in manufacturing memory technologies, significantly impacting the production of DRAM and NAND Flash chips. This process aims to maximize the number of functional units from each silicon wafer, directly affecting the economics of memory chip production. By improving yield rates, manufacturers can lower the cost per unit, making the production more economically viable and allowing for competitive pricing in the memory market.

Implementing Yield Management for Quality and Efficiency

Implementing advanced yield management strategies, such as process control, quality assurance, and fault diagnosis, is essential for achieving high yield rates. These strategies guarantee that manufacturing processes are optimized, defects are minimized, and the overall quality of memory chips is improved. The result is a more reliable product that meets the high standards expected by consumers and industries, improving the manufacturer’s reputation and product demand.

Moreover, yield optimization grants manufacturers a competitive edge by enabling them to operate more efficiently. Efficient production processes mean companies can respond quickly to market demands while introducing new products faster and at a lower cost.

Focusing on yield optimization supports the stability of the supply chain through a consistent output of memory chips, which is vital for meeting the technology sector’s ongoing demands. It also promotes environmental sustainability by reducing waste generated in the production process, aligning with global efforts toward more responsible manufacturing practices.

Challenges in Memory Chip Manufacturing

The production of memory chips faces significant challenges due to the inherent complexities of semiconductor manufacturing.

These challenges stem from the precision required in fabricating devices at the nanometer scale, where even minor anomalies can significantly impact the final product’s functionality and reliability. The need for flawless execution in memory chip production is paramount, as these components are critical for a wide range of electronic devices.

Addressing Defects and Process Variations

One of the primary hurdles in manufacturing memory chips is the occurrence of defects and process variations. Defects can arise from many sources, including material impurities, photolithography inaccuracies, and inconsistencies in etching and deposition processes.

Similarly, process fluctuations in manufacturing conditions may lead to significant chip performance and yield deviations. These issues reduce the output of functional chips and increase the cost of production, affecting the economic viability of manufacturing operations.

The Need for Advanced Yield Management Solutions

The challenges posed by defects and process variations highlight the necessity for advanced yield management solutions in the production of memory technologies. Advanced yield management encompasses a suite of techniques and technologies designed to monitor, analyze, and optimize the manufacturing process.

These improvements are critical for maintaining competitiveness in the fast-paced memory market, guaranteeing the production of high-quality memory chips while mitigating the financial risks associated with low yields.

Improving Production Through Yield Optimization

Yield optimization plays a crucial role in addressing the challenges faced in memory technology manufacturing. Manufacturers can achieve higher efficiency and better product quality by focusing on continuously improving production processes and reducing defects.

This supports the economic viability of memory chip production, supply chain stability, and technological innovation in the industry. As the demand for more advanced and reliable memory solutions continues to grow, implementing advanced yield management and optimization strategies will be vital in overcoming the complexities of semiconductor manufacturing.

Advanced Yield Management Techniques

Yield management in the context of semiconductor manufacturing, particularly for memory technologies such as DRAM and NAND Flash, employs advanced techniques to address production challenges. These methodologies are designed to improve the efficiency and output of memory chip production, focusing on boosting the precision of manufacturing processes and the quality of the final product.

Process Control in Memory Manufacturing

Process control in memory manufacturing is a key aspect of yield management. This strategy involves the detailed observation and adjustment of manufacturing processes to reduce variability and defects. Through real-time data collection and analysis, manufacturers can detect and correct deviations quickly, guaranteeing that production meets stringent specifications. This rigorous control is vital for securing high yields and guaranteeing the quality of memory chips.

Quality Assurance in Memory Chips

Quality assurance in memory chips focuses on confirming that the final products meet high standards of performance and longevity.

This is achieved through during-production inspections, testing, and evaluations after production. Implementing thorough quality assurance protocols allows manufacturers to identify and resolve issues before the products are distributed, significantly lowering the chance of product failures.

Fault Diagnosis in Memory Production

Fault diagnosis in memory production is essential for determining the causes of defects and inefficiencies within the production line. Advanced diagnostic techniques, such as automated optical inspection (AOI) and electrical testing, are employed to locate specific issues. This allows for targeted interventions, minimizing downtime and improving yield effectiveness.

Data Analysis for Yield Improvement

Data analysis for yield improvement is integral to contemporary yield management strategies. Manufacturers can extract valuable insights from large production data volumes by applying data analytics and machine learning technologies. These insights are instrumental in implementing predictive maintenance, refining production processes, and identifying early signs of potential yield disruptions.

Benefits of Advanced Yield Management for Memory Technologies

Utilizing advanced yield management strategies offers multiple advantages for producing memory technologies. It uplifts the economic viability of memory manufacturing by decreasing the costs linked to waste and redoing work.

It also strengthens the competitive advantage in the memory market by enabling faster introductions of new products and technologies. Technological innovation in memory chips benefits from continuous improvements in manufacturing processes, while supply chain stability in the memory industry is improved through more dependable and uniform production outcomes.

Focusing on waste reduction in memory chip production boosts economic efficiency and supports environmental protection efforts. It offers many benefits for producing memory technologies, directly impacting cost, quality, and innovation. Here’s how:

1. Cost Efficiency and Economic Viability

By improving yield rates, advanced yield management significantly reduces the cost per unit of memory chips. This reduction in production costs makes operations more financially viable, allowing manufacturers to offer competitive pricing without compromising profit margins.

2. Better Product Quality and Reliability

The application of precise process controls and quality assurance measures guarantees that memory chips meet high standards of quality and reliability. This reduces the likelihood of product failures and builds consumer trust.

3. Competitive Edge in the Semiconductor Industry

Manufacturers who implement advanced yield management techniques can better respond to market demands and technological shifts, maintaining a competitive edge. This agility is key in the fast-paced semiconductor industry, where staying ahead of technological curves is essential.

4. Supply Chain Stability and Predictability

With improved yield rates and production efficiencies, manufacturers can ensure more stable and predictable supply chains. This reliability is essential for meeting delivery commitments and maintaining customer satisfaction in a volatile market.

5. Environmental Sustainability through Waste Reduction

Advanced yield management contributes to environmental sustainability by minimizing waste produced during the manufacturing process.

6. Rapid Prototyping and Iterative Design

Advanced yield management allows faster prototyping and iterative design processes. This means new concepts can be tested and refined more quickly, speeding up the time from design to market.

7. Continuous Process Improvement

At the core of advanced yield management is the principle of continuous improvement. By constantly analyzing performance data and refining processes, manufacturers can achieve incremental gains in efficiency, quality, and yield for long-term competitiveness and growth.

Future Trends in Memory Technologies Yield Management

The evolution of yield management within data storage technologies is set to undergo transformative changes driven by technological advancements and shifting demands within the industry.

Here’s a focused exploration of upcoming trends and their implications:

Artificial Intelligence and Machine Learning Integration

The adoption of artificial intelligence (AI) and machine learning (ML) in yield management signifies a major shift towards more intelligent data analysis and decision-making. These technologies provide better opportunities for optimizing processes, leading to superior yield rates and diminished production expenses.

Emphasis on Big Data Analytics

The exponential growth of data from memory technology manufacturing necessitates strong big data analytics. This approach is instrumental in deciphering the vast information generated, offering actionable insights for yield enhancement. yieldWerxTM utilizes big data analytics to aid manufacturers in detecting patterns and anomalies, facilitating informed decision-making.

Adoption of Advanced Process Control (APC)

Increased reliance on Advanced Process Control (APC) systems is anticipated, promoting real-time adjustments to manufacturing processes based on analytical data. These systems contribute to maintaining optimal conditions throughout production. yieldWerx supports APC implementation through its comprehensive data analysis tools, enabling effective process adjustments.

Internet of Things (IoT) and Improved Connectivity

Integrating Internet of Things (IoT) technology within manufacturing environments promises to streamline yield management for memory production. This integration allows for more efficient and thorough data collection and precise control over production nuances.

Focus on Sustainability and Waste Minimization

Sustainability remains a focal point, with yield management vital in minimizing waste and promoting environmental responsibility. Techniques that uplift yield also reduce material and energy use per chip, reflecting a commitment to environmental goals. yieldWerx’s approach emphasizes efficiency and reduction of waste, aiding manufacturers in lessening their environmental footprint.

Development of Collaborative Ecosystems

The future will likely see the creation of more collaborative environments, streamlining the exchange of data and best practices among manufacturers, suppliers, and solution providers like yieldWerx. This collective approach is expected to spur innovation and methodologies for yield optimization across the industry.

How yieldWerx can Help with Advanced Yield Management

YieldWerx offers a range of modules that can significantly benefit memory technologies through advanced yield management. These modules fall under basic and advanced categories, designed to cater to various aspects of semiconductor manufacturing, including data management, analysis, and equipment efficiency.

Core and Basic Modules

- Automated Data Loading: Supports automated loading of data, distinguishing between good and bad data.

- Reporting & Analysis: Delivers production yield reports accessible by various internal and external stakeholders.

- Data Archive/Purge Module: Provides a comprehensive set of data archive and purging settings for different product life cycles.

- Standard Data Access For External Tools: Allows tools like SAS, JMP, and Excel to access data from standard or customized data views.

Advanced Modules

- Custom Limits Manager: Facilitates the creation and management of custom sets of limits for analysis, avoiding manual input.

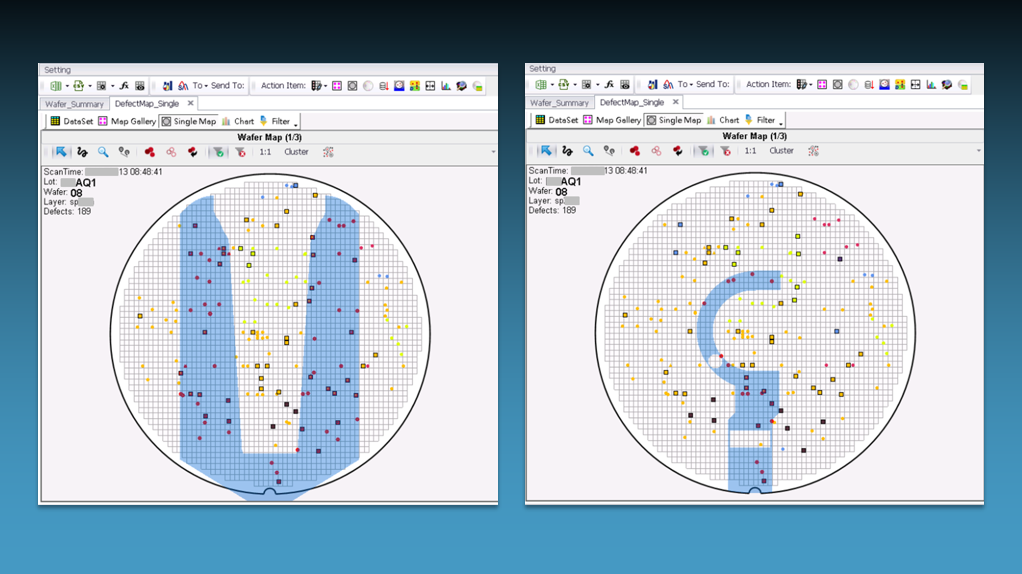

- Defect Data Management: Manages metrology/defect data, performs defect classification, and correlates defect data with test data.

- Inspect Image Management: Collects inspection data automatically, associating it with wafers/die/units and manufacturing equipment.

- Memory/Optical Bitmap: Automatically constructs image maps for memory or optical arrays using failing data for pattern recognition.

- Overall Equipment Efficiency: Monitors equipment utilization and efficiency, integrating with MES platforms to correlate test data.

- Real-Time Handler and Prober Control Module: Controls the prober in real-time, collecting test data and adjusting probing patterns accordingly.

- Returned Material Analysis Containment: Identifies lots, wafers, and variables standard to failed devices for rapid assessment and containment.

- Test Program Management: Manages test program releases, supporting systematic and documented processes.

These modules help improve yield management by offering solutions for data analysis, equipment efficiency, and defect management, among other things. They are designed to improve the manufacturing process of memory technologies by providing detailed insights, automating processes, and improving product quality and reliability.

Conclusion

Advanced yield management is crucial for producing high-quality memory chips, impacting cost, quality, and sustainability. Manufacturers can significantly improve yield rates and product reliability while reducing production costs by implementing process control and data analysis strategies.

These efforts also support environmental goals by minimizing waste. As the demand for advanced memory solutions grows, powerful tools offered by yieldWerx are essential for optimizing manufacturing processes.

Check out how yieldWerx is shaping the future of memory technology!