In recent years, the semiconductor industry has faced unprecedented disruptions. From the COVID-19 pandemic and geopolitical tensions to natural disasters and raw material shortages, these challenges have illuminated fundamental vulnerabilities within the semiconductor supply chain. The importance of supply chain resilience is unmistakably clear. But resilience doesn’t just come from having backup suppliers or stockpiling inventory—it comes from leveraging data integration to make more informed, agile decisions that can withstand any disruption.

A collapsed building, following the earthquake in Hualien, Taiwan on April 3rd, 2024

As industry professionals, we need to shift our mindset from reactive to proactive. Data integration is the key enabler of this transformation. In this blog post, we’ll explain how semiconductor companies can strengthen their supply chain resilience by embracing advanced data integration strategies and technologies.

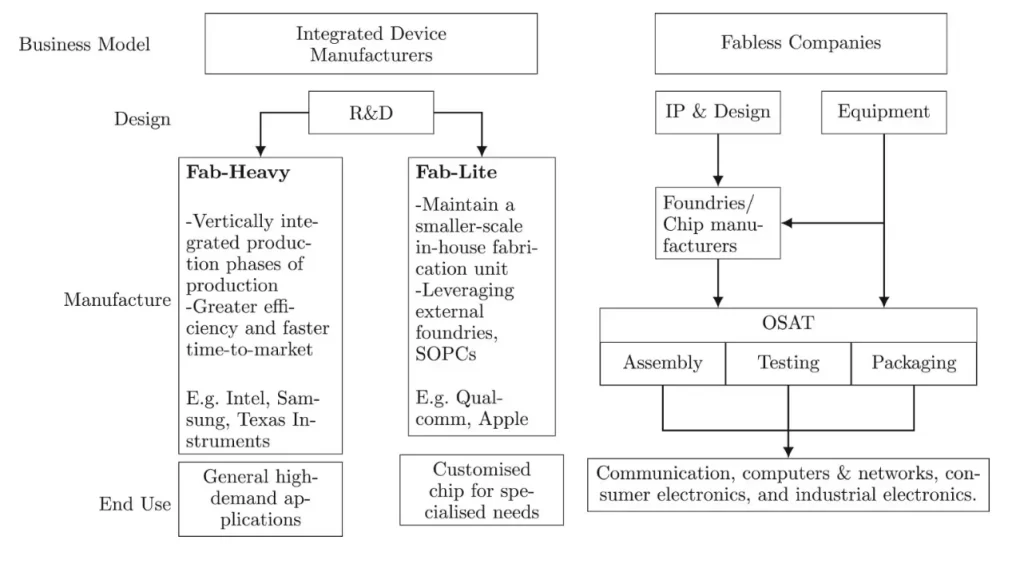

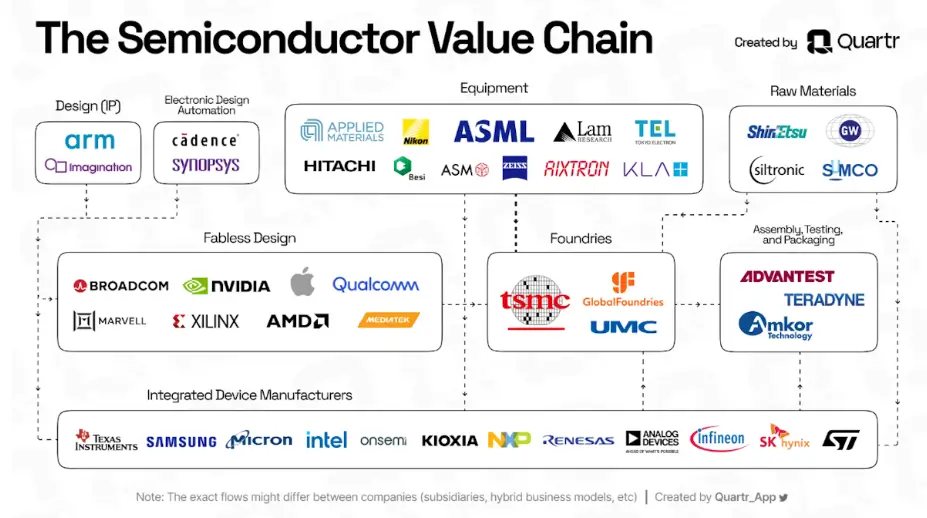

The Growing Complexity of Semiconductor Supply Chains

The semiconductor supply chain is notoriously complex. It involves numerous stages—research and development (R&D), fabrication, assembly, testing, packaging, and distribution. Each stage relies on a network of suppliers, many of which are located in different parts of the world.

This globalized network has been indispensable in driving innovation, but it has also created a system prone to risk. The COVID-19 pandemic revealed how fragile global supply chains can be. As a result, industries reliant on semiconductors, such as automotive, consumer electronics, and telecommunications, experienced significant setbacks. The automotive sector alone absorbed $200 billion USD in losses due to chip shortages, while the broader impact extended across multiple industries, with some disruptions lasting for years.

However, the challenges are not limited to pandemics or geopolitical disruptions. Issues such as trade barriers, natural disasters, and raw material shortages continue to plague the industry. The semiconductor sector, especially as demand increases for advanced technologies like AI, EVs, and 5G, can no longer afford to operate reactively.

Data Integration as the Foundation of Resilience

Data integration isn’t just about connecting systems—it’s about creating a unified, transparent view of a business’ supply chain. This enables companies to anticipate disruptions, make real-time decisions, and respond proactively to challenges. With integrated data, a business can:

- Monitor supplier performance in real-time

- Optimize inventory management to avoid stockouts and overstocking

- Track production schedules and shipping delays

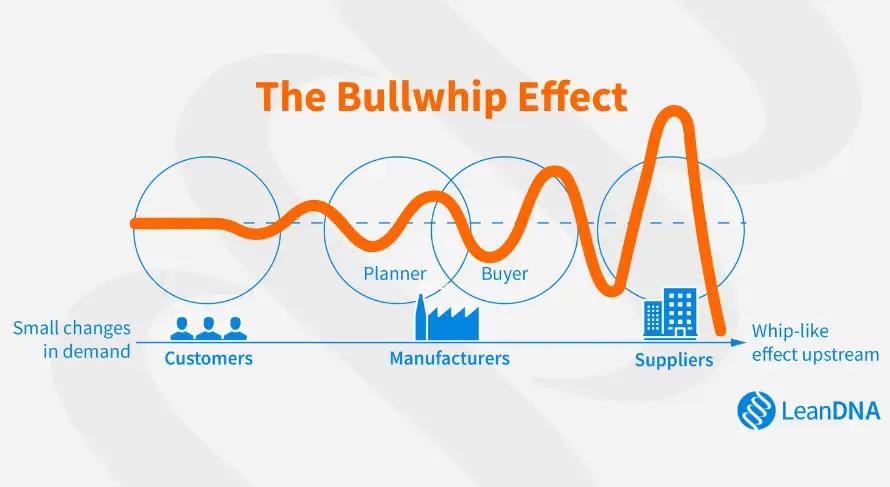

- Leverage predictive analytics to foresee supply chain fluctuations also called the bullwhip effect.

The bullwhip effect is a supply chain phenomenon where minor variations in customer demand at the retail level lead to increasingly larger demand fluctuations as they move upstream—impacting wholesalers, distributors, manufacturers, and raw material suppliers.

The goal is to remove silos and create a comprehensive, connected ecosystem where every player—internally and externally—has access to the right data at the right time. With this level of visibility, decision-makers can make informed decisions to keep production on track and mitigate risks before they materialize.

Mapping and Analyzing Semiconductor Manufacturing Chain

ASML Transports DUV Machines at the Airport, Monitoring Temperature, Vibration Coefficients, and Other Data Throughout the Process. Source: ASML

The first step toward building a resilient supply chain is to map and analyze the entire semiconductor manufacturing chain. This means understanding every link in a business’s supply chain, from raw material suppliers to final product distributors.

Decision-makers must:

- Identify key suppliers and assess their roles in the ecosystem. Who are the critical suppliers? What are their strengths and weaknesses?

- Evaluate dependencies and vulnerabilities—where is the business most reliant on a single supplier or region? A breakdown in one region can ripple through the entire network.

- Assess transportation and logistics routes—what are the critical transit points, and where do delays often occur?

By integrating data at every stage, one can pinpoint risks and vulnerabilities that may have otherwise gone unnoticed. This proactive mapping will not only help analysts anticipate potential problems but also create backup plans for when disruptions occur.

Risk Mitigation Through Data-Driven Insights

Supply chain disruptions can be caused by many factors. The key to minimizing these disruptions is early detection.

Here’s how data integration facilitates risk mitigation:

Predictive Analytics:

By integrating data from suppliers, logistics, and production systems, companies can use AI and machine learning (ML) to predict potential disruptions before they occur. For example, AI algorithms can analyze historical data and identify patterns that signal when a specific supplier or region may face issues.

Automated Alerts:

Real-time data integration ensures businesses are immediately alerted if any critical issue arises. For example, if a shipment from a key supplier is delayed, supply chain experts know about it before it impacts production, allowing them to make prompt adjustments.

Scenario Planning with Digital Twins:

Digital twins are transforming supply chain resilience by enabling both real-time visibility and advanced scenario planning. By creating a virtual replica of physical assets, operations, and logistics flows, companies can continuously monitor their supply chain in real time—identifying inefficiencies, bottlenecks, and disruptions as they emerge.

More importantly, digital twins allow businesses to simulate potential disruption scenarios—whether it’s a pandemic resurgence, geopolitical tension, or a natural disaster—and evaluate how the supply chain would respond.

This level of insight empowers stakeholders to make faster, data-driven decisions and implement proactive strategies to optimize operations, reduce risk, and improve overall supply chain agility. Top companies like Siemens, Microsoft, General Electric and Pfizer are already making use of this technology for optimizing their supply chain operations.

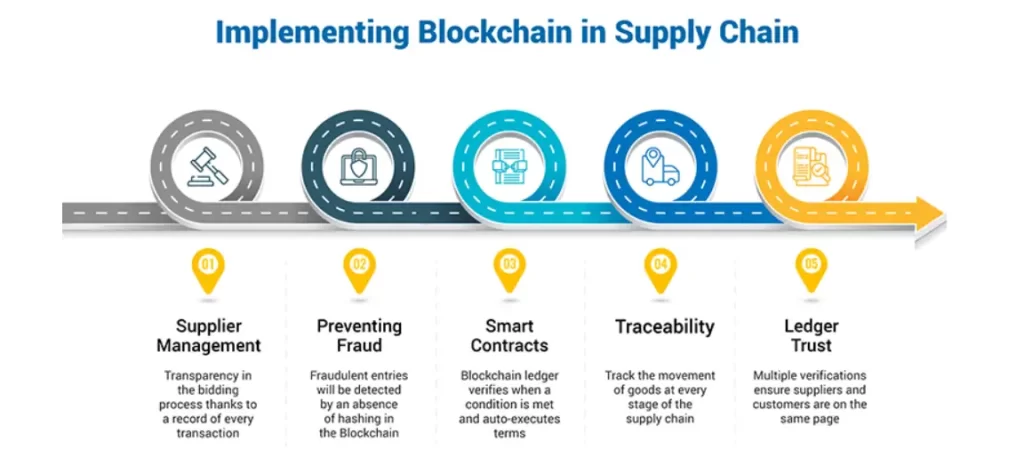

Leveraging Blockchain for Transparency and Security

Source: GEP

In today’s world, transparency is a critical part of building resilience. In the semiconductor industry, there are numerous points in the supply chain where valuable data is at risk of being manipulated, lost, or misplaced—especially when dealing with proprietary intellectual property or sensitive logistical information.

Blockchain technology can secure and validate every step of the semiconductor manufacturing process. By ensuring that all transactions are immutable and traceable, blockchain fosters trust across all supply chain participants—from suppliers to manufacturers to end customers.

Incorporating blockchain into supply chain operations can help:

- Ensure data integrity, especially when dealing with sensitive IP or high-value components

- Enable end-to-end traceability, from raw materials to finished products

- Strengthen supplier relationships, as data integrity and transparency become a standard practice

Connecting Supplier Data with Internal Yield Metrics

Yield performance cannot be fully understood in isolation from upstream inputs. Connecting supplier data with internal yield metrics enables manufacturers to identify hidden patterns and correlations between material quality, process variation, and test outcomes. For example, fluctuations in wafer flatness, resist uniformity, or chemical purity from a specific supplier can subtly degrade yield across multiple lots—yet these issues often go unnoticed when data is siloed.

By integrating external data sources such as supplier lot history, material certifications, and logistics conditions with internal test and parametric data, companies can uncover the true root causes of yield excursions. This proactive alignment not only supports more accurate failure analysis but also empowers strategic supplier engagement, preventive quality controls, and early warning systems.

Ultimately, integrated data ecosystems strengthen visibility, accountability, and collaboration across the supply chain—leading to more resilient operations and improved product quality.

Conclusion: A Future-Proof Semiconductor Supply Chain

The semiconductor industry stands at a crossroads, grappling with mounting pressures from geopolitical instability, rapid technological evolution, and persistent supply chain disruptions. The path forward lies in embracing data integration as a strategic foundation for building resilient, transparent, and agile supply networks. By breaking down data silos and enabling real-time visibility across suppliers, fabs, and test environments, companies can transform reactive operations into predictive, adaptive ecosystems.

This transformation isn’t theoretical—it’s already happening. yieldWerx is leading the charge by helping semiconductor manufacturers connect supplier data, internal yield metrics, and test results into a single source of actionable insight. Our solutions empower engineers to detect issues earlier, trace yield degradation to upstream causes, and implement closed-loop feedback across the value chain.

As we look to 2025 and beyond, organizations that invest in integrated analytics and intelligent yield management will be the ones best prepared to anticipate disruptions, optimize performance, and maintain competitive advantage in an increasingly unpredictable world. Data-driven resilience is no longer optional—it’s the new industry standard.

Start building a smarter, more resilient supply chain today with data-driven yield insights.

👉 Explore how yieldWerx can empower your team to connect the dots between suppliers, test data, and yield performance. Contact Us Today to book a demo.