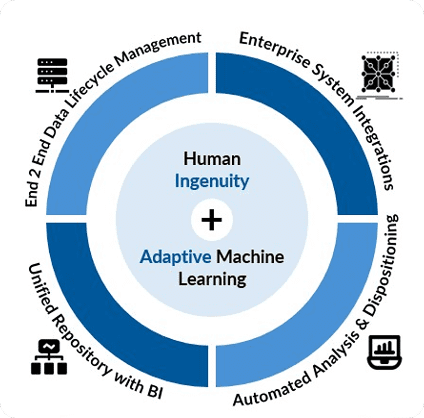

Actionable insight begins with good, clean data. Our four foundational components, which sit at the heart of our architecture, enable just that. We not only facilitate the secure integration of data across the entire semiconductor lifecycle, but we also scrub and augment it with critical information, removing bad data and utilizing automation to ensure easy accessibility.

A robust architecture that supports complex data retention rules.

Facilitates bi-directional data integrations across industry tools and manufacturing engineering systems.

Single source-of-truth database harmonizing data across semiconductor lifecycle. yieldWerx still enables users and companies to create as many databases as they need – practical uses of this feature include the ability to have Engineering, Production, Characterization databases etc.

Automated data acquisition with cleaning and data augmentation.

Customizable and cleverly designed, our product modules are architected to be easily integrated, providing only the solutions you need, on your timeline and within your budget.

Holistic end-to-end data visualizations and insight

Advanced Product customizations for wafer, reticle, and die

Management of the metrology, critical dimension, images, and defect data

Robust outlier detection algorithms including PAT++, Zonal Pat, Nearest neighbor residual

Ink and inkless wafer and reticle mapping allowing full control and seamless integration

Real-time or passive data collection from equipment

Merges and redefines unique wafer and data sets, automating the merging process

Proactive real-time lot and wafer/screen management equipped with advanced AI

IP and Test parameter traceability that can track IP blocks and their specifications

Stringent test program release controls with version control of test program files

| Modul/Customer | Fabless | IDM | OSAT | Foundries | Product Engineering Service |

Test Equipment Manufacturer |

|

|---|---|---|---|---|---|---|---|

| Product Suite | Process/Yield Analytics and Reporting | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Product/Device Setup | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Quality Control and Risk Containment | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Multi-Dimensional Wafer Merge | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Automated Lot Disposition | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Real-time Machine Control and Monitoring | ✓ | ✓ | ✓ | ✓ | |||

| Assembly Map Generation | ✓ | ✓ | ✓ | ✓ | |||

| Parameter Genealogy | ✓ | ✓ | ✓ | ✓ | |||

| Defect Management | ✓ | ✓ | ✓ | ✓ | |||

| Test Program/Recipe Management | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Foundational | Unified Repository with BI | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Automated Analysis & Dispositioning | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| End 2 End Lifecycle Management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Enterprise Systems Integrations | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Modul/Customer | ASIC/ MSP/ Analog |

MEMS | Digital | Automotive | Life Science |

Aerospace and Defence |

Consumer Electronics |

Semi Equipment |

|

|---|---|---|---|---|---|---|---|---|---|

| Product Suite | Process/Yield Analytics and Reporting | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Product/Device Setup | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Quality Control and Risk Containment | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Multi-Dimensional Wafer Merge | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Automated Lot Disposition | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Real-time Machine Control and Monitoring | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Assembly Map Generation | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Parameter Genealogy | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Defect Management | ✓ | ✓ | ✓ | ✓ | ✓ | ||||

| Test Program/Recipe Management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Foundational | Unified Repository with BI | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Automated Analysis & Dispositioning | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| End 2 End Lifecycle Management | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Enterprise Systems Integrations | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Module/Product Stage | NPI | Volume Production | Advanced | |

|---|---|---|---|---|

| Product Suite | Process/Yield Analytics and Reporting |

✓ | ✓ | ✓ |

| Product/Device Setup | ✓ | ✓ | ✓ | |

| Quality Control and Risk Containment |

✓ | ✓ | ||

| Multi-Dimensional Wafer Merge |

✓ | ✓ | ||

| Automated Lot Disposition |

✓ | ✓ | ✓ | |

| Real-time Machine Control and Monitoring |

✓ | ✓ | ||

| Assembly Map Generation |

✓ | ✓ | ||

| Parameter Geneaology | ✓ | ✓ | ||

| Defect Management | ✓ | ✓ | ✓ | |

| Test Program/Recipe Management |

✓ | ✓ | ✓ | |

| Foundational | Unified Repository with BI | ✓ | ✓ | ✓ |

| Automated Analysis & Dispositioning |

✓ | ✓ | ✓ | |

| End 2 End Lifecycle Management |

✓ | ✓ | ||

| Enterprise Systems Integrations |

✓ | ✓ | ✓ |

Discover the yieldwWerx difference and revolutionize your semiconductor operations. Schedule a demo today!