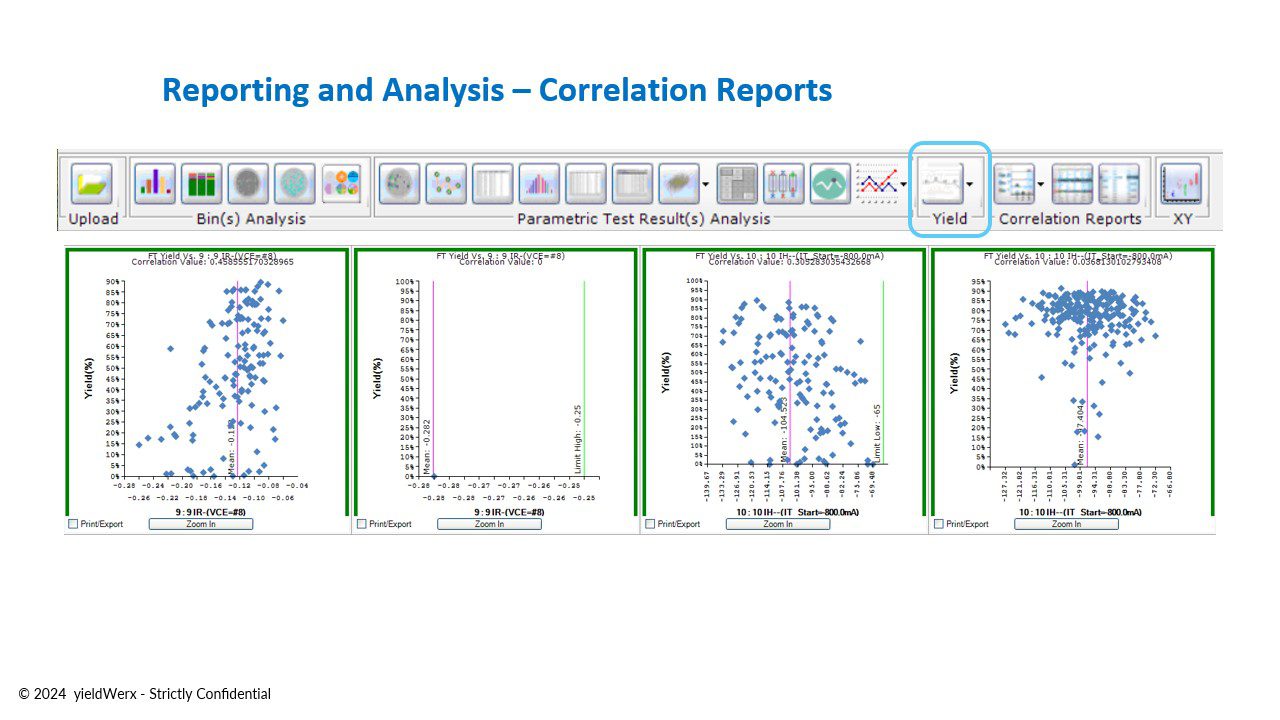

This powerful module is designed to eliminate the manual intervention and analysis typically required by engineers. Equipped with advanced AI and ML algorithms, it enables rapid data analysis within minutes, allowing for the examination of significantly larger data sets than standard practices permit. The module aids in predicting commonality correlations and provides comprehensive manufacturing control. It features real-time alerts to hold or redirect lots, identifies complex lot commonalities by analyzing historical trends, and automates lot categorization through an extensive reporting module. Furthermore, this functionality seamlessly integrates with various enterprise systems, including MES, enhancing overall operational efficiency.

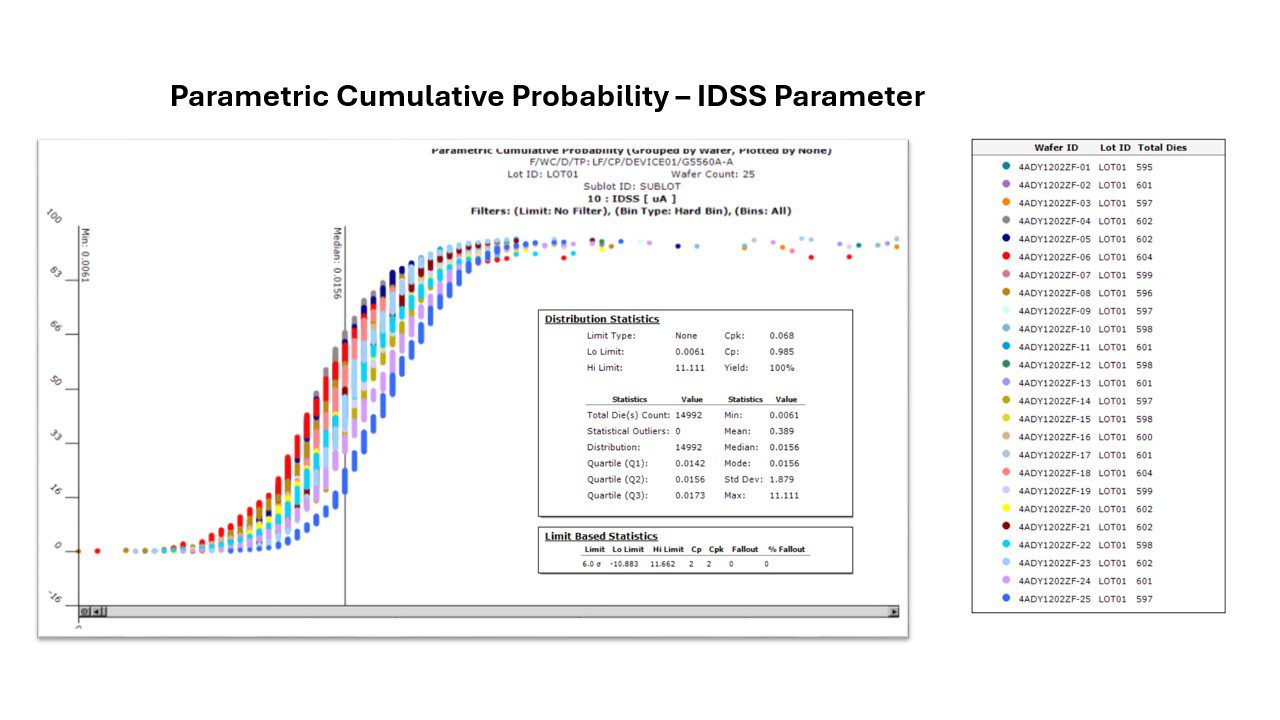

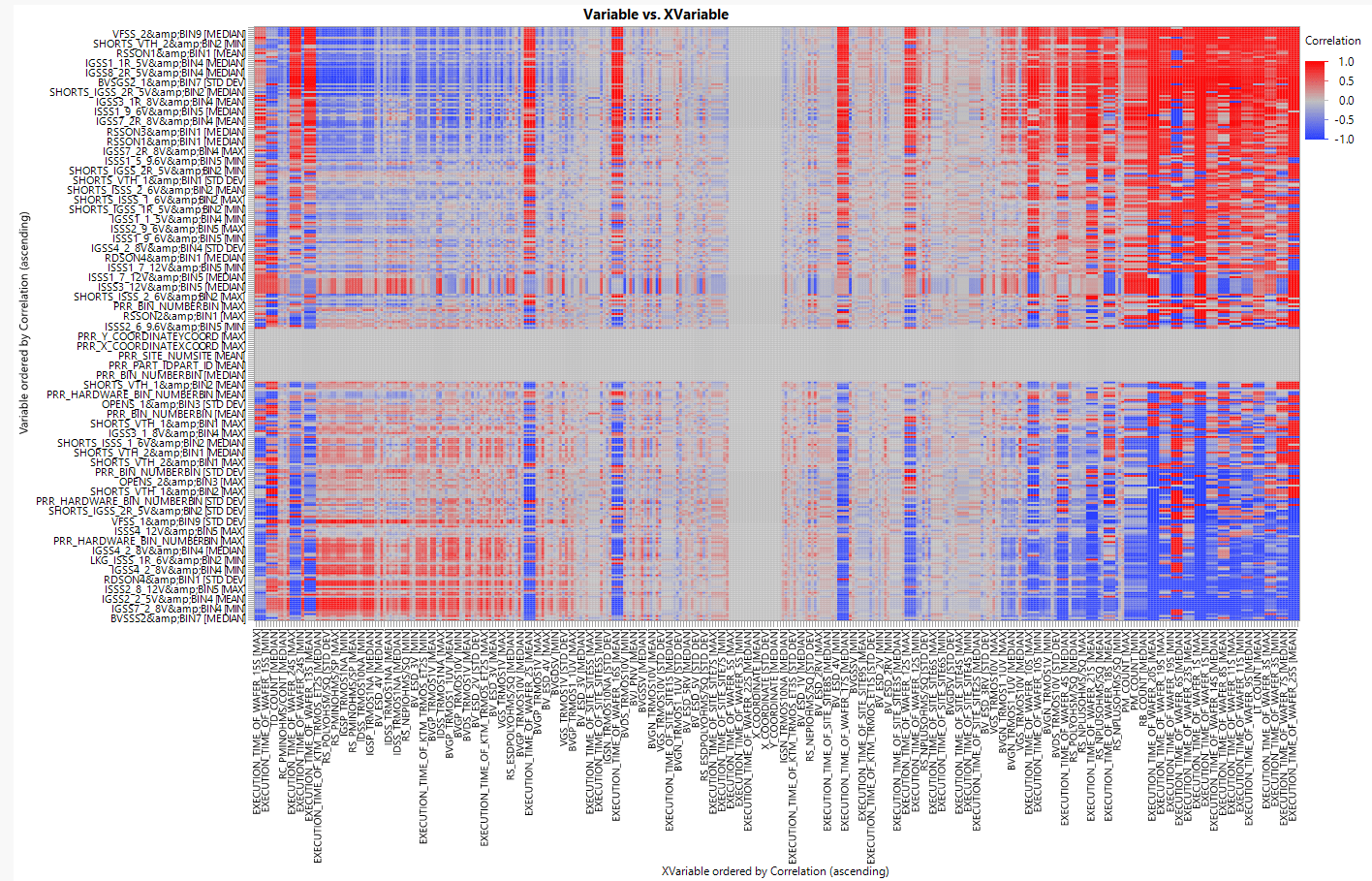

Utilizes the power of AI/ML to perform in-depth cross-center correlation analysis through geospatial pattern recognition to identify systemic causes of yield loss. These causes may originate from association rules, analysis of variance (ANOVA), contingency tables, and commonalities occurring at specific manufacturing and test stages throughout the product lifecycle. This enables Feed Forward (FF) rules and analysis to be activated.

Root Cause Analysis (RCA) for low-yielding lots, wafers, customer returns, and other lot disposition scenarios. AI/ML-powered knowledge graphs visually guide users through various weighted paths to help identify root causes, simplifying model updates and reducing the time-consuming manual analysis of complex tables and data.

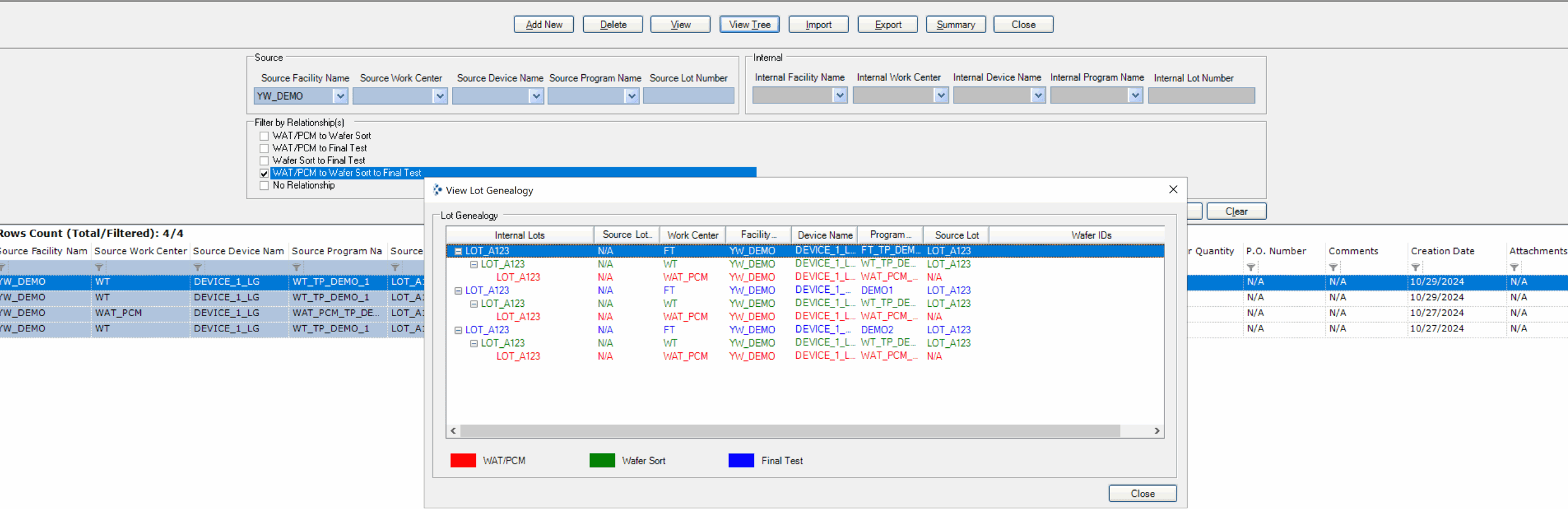

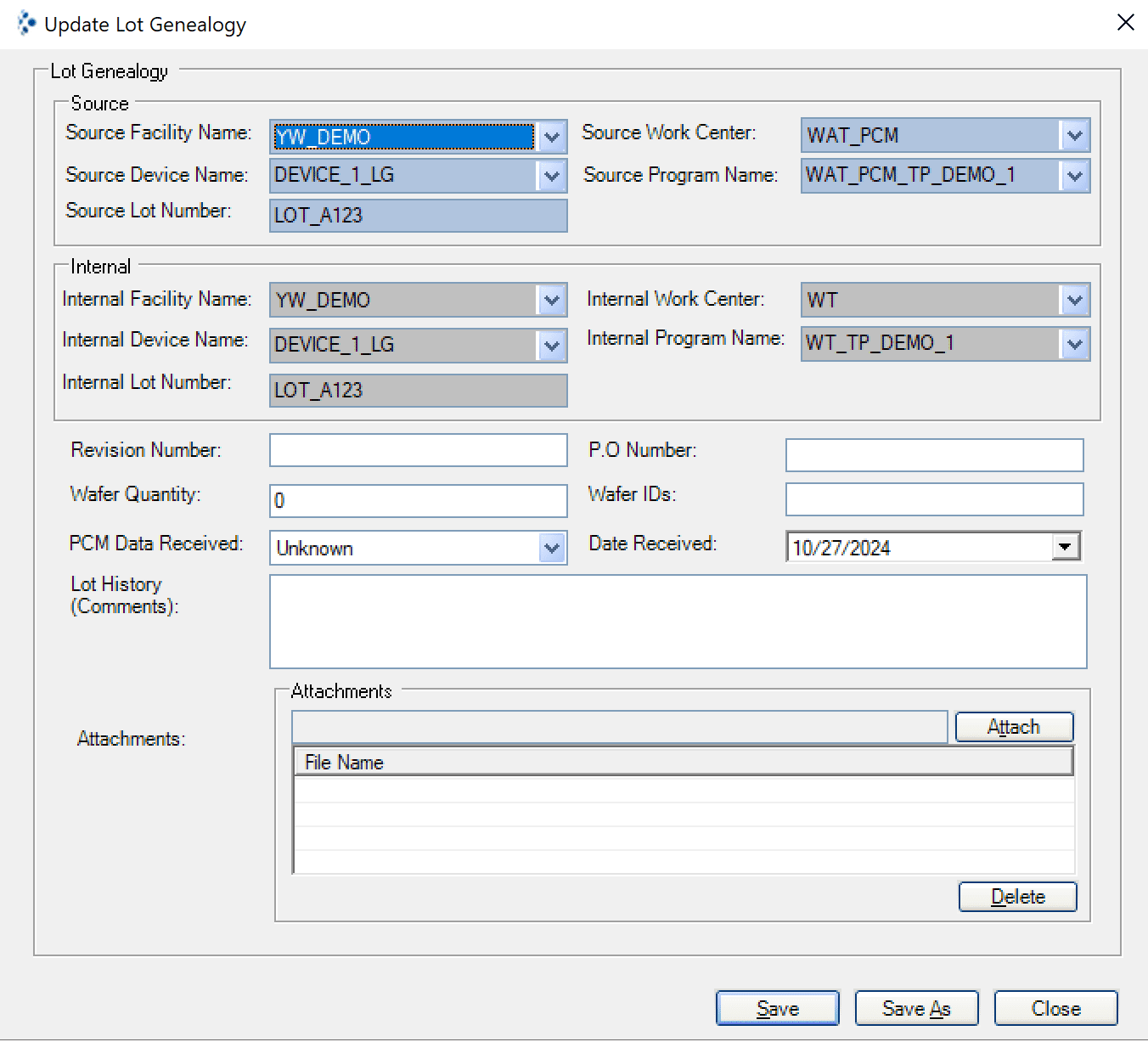

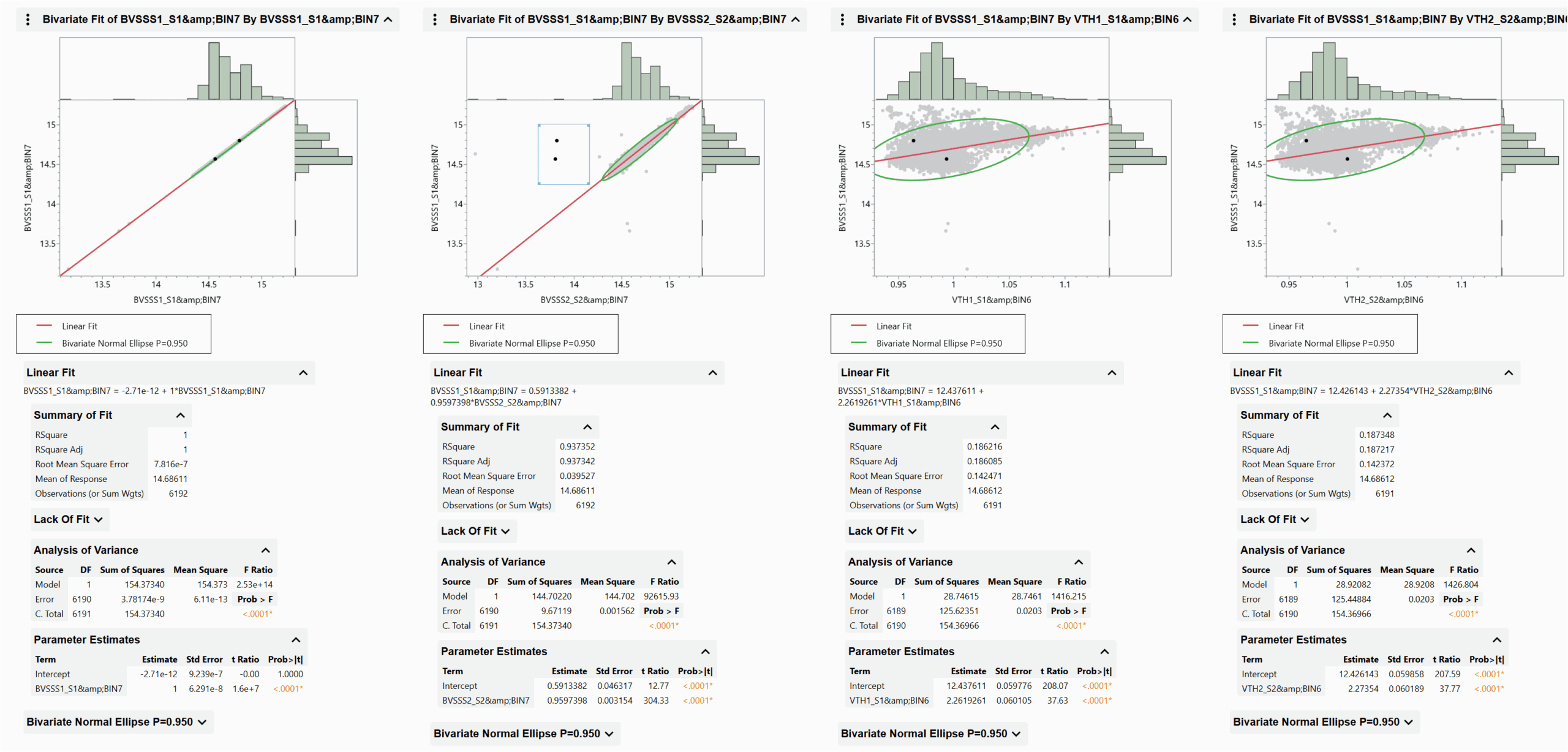

Lot Genealogy enables yieldWerx to provide traceability at the Lot, Wafer, and Die levels, from Manufacturing Processes (Lot Splits, Recipe Splits, Engineering Work, and Special Work Requests) in the Fab to Sort & Final Assembly, Packaging (2.5/3D Stacking), and all the way to System and Board-level traceability. It also supports rapid RMA and Impact analysis, among other capabilities, and enables the AI/ML features of yieldWerx.