yieldWerx provides the ability to ingest data from any process, equipment, or signal- generating process in real time or at summarized/sample data into yieldWerx and then apply statistical rules to the data, allowing for immediate analysis and response to any deviations from established parameters. With options for real-time or passive real-time data collection from manufacturing equipment, this module collects Device Under Test (DUT) data, live wafer maps, and monitors full parameters. The module can also create adaptive prober wafer maps that can isolate test locations that require further testing, adjust testers to only retest defective areas instead of full wafers, hence minimizing retest times and unnecessary touchdowns.

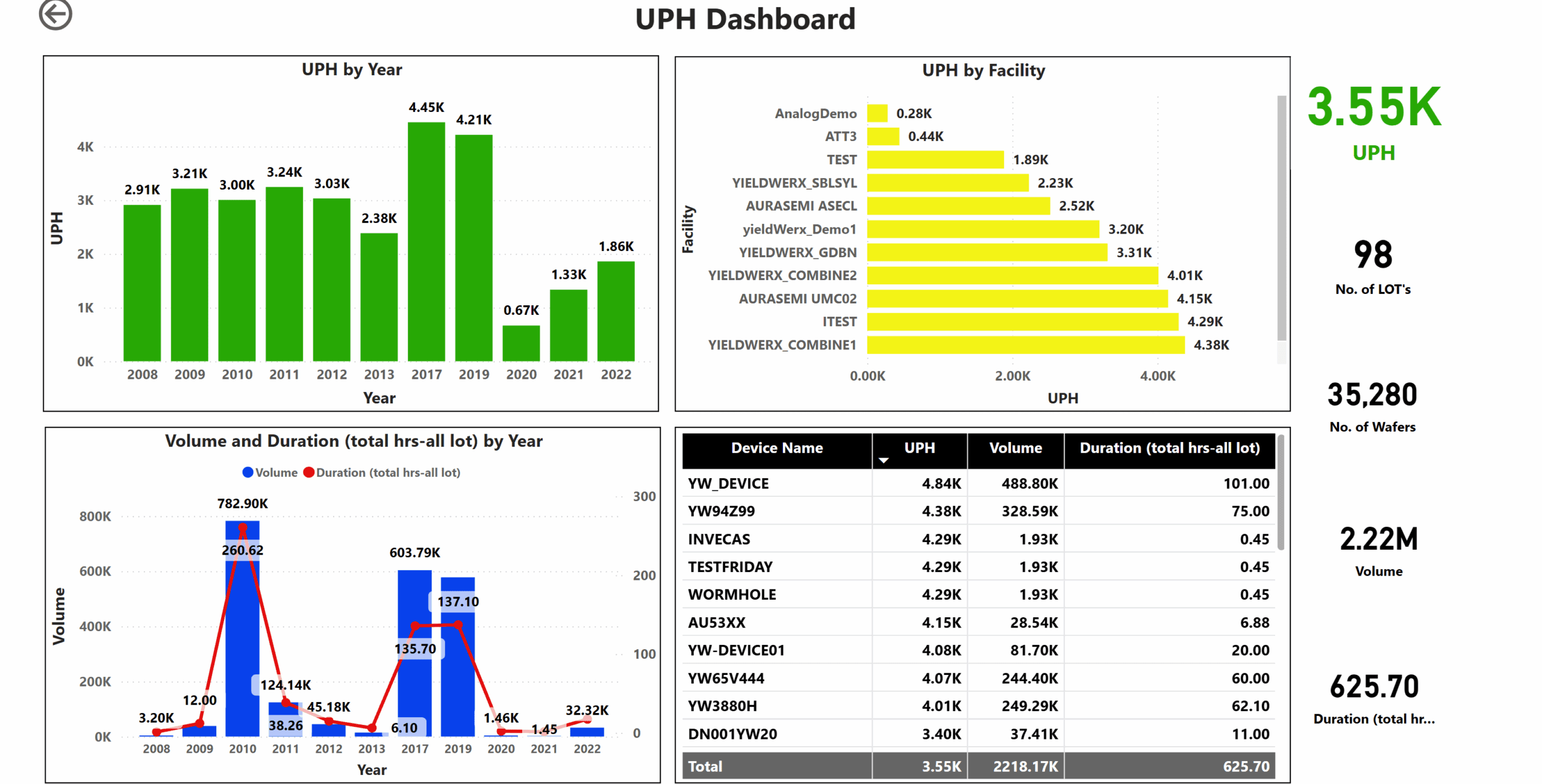

Overall Equipment Effectiveness (OEE) is a key metric in manufacturing that assesses the efficiency of machinery by evaluating its performance against its full potential. In environments with numerous testers, probers, handlers, and associated components like probe cards and load boards, managing operations can be complicated. yieldWerx ensures accurate testing of wafers and parts, maintaining equipment health, and meeting operational targets becomes a significant challenge in such complex setups.

yieldWerx streamlines the Return Material Authorization (RMA) analysis process for users by utilizing the Lot Genealogy Module alongside AI and Machine Learning (ML) for Commonality Analysis. This combination helps identify the reasons for undetected escapes, ascertain the impact on other lots or materials, and enhance the AI/ML models to detect additional anomalies, thereby preventing recurrence of similar issues. The Root Cause Analysis (RCA) is subsequently supported by the AI/ML module, facilitating the generation of comprehensive RMA analysis.

The yield prediction analysis module enables users to assess data from the entire product test supply chain to forecast potential yield losses. This functionality supports supply chain planning while also guiding Root Cause Analysis (RCA) and yield enhancement efforts. The yield prediction analysis utilizes AI and Machine Learning (ML) techniques, incorporating data from testing as well as accessible manufacturing process data for more accurate yield predictions.