Unlike Fabless customers, which focus on designing products, and foundries, which focus on the production line, IDMs are large-scale semiconductor companies that have the means to do everything from designing to producing products.

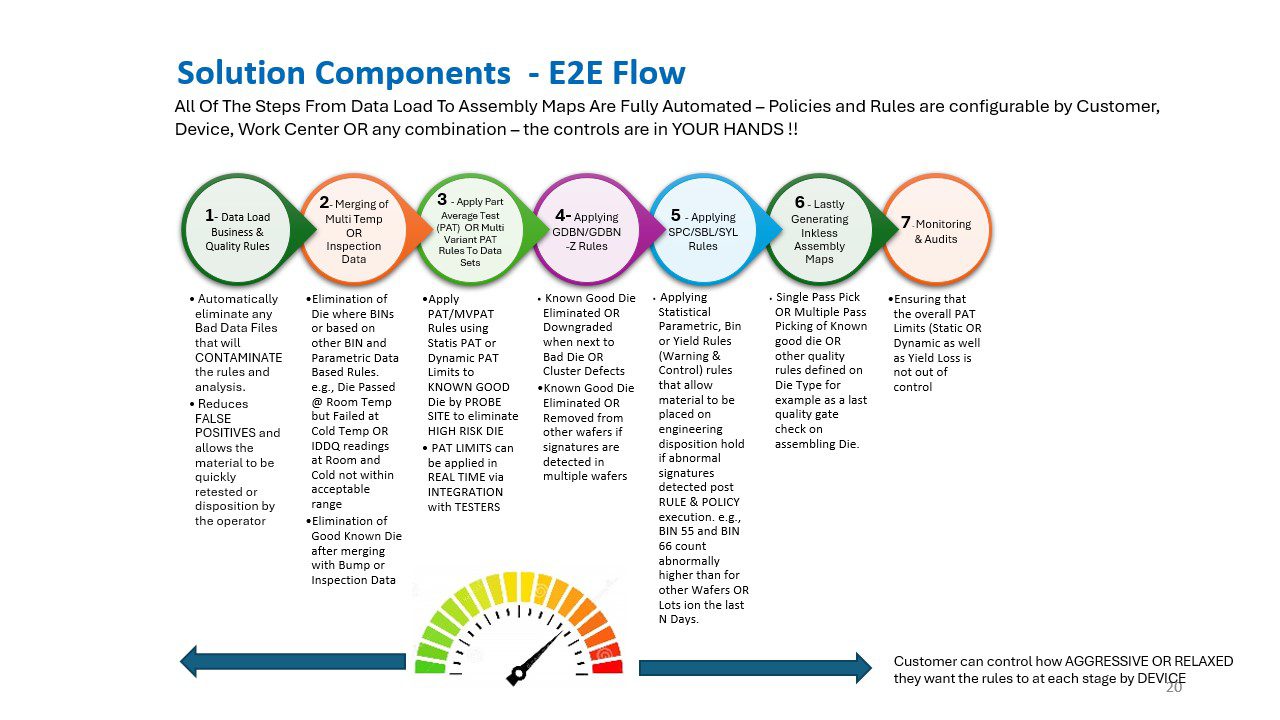

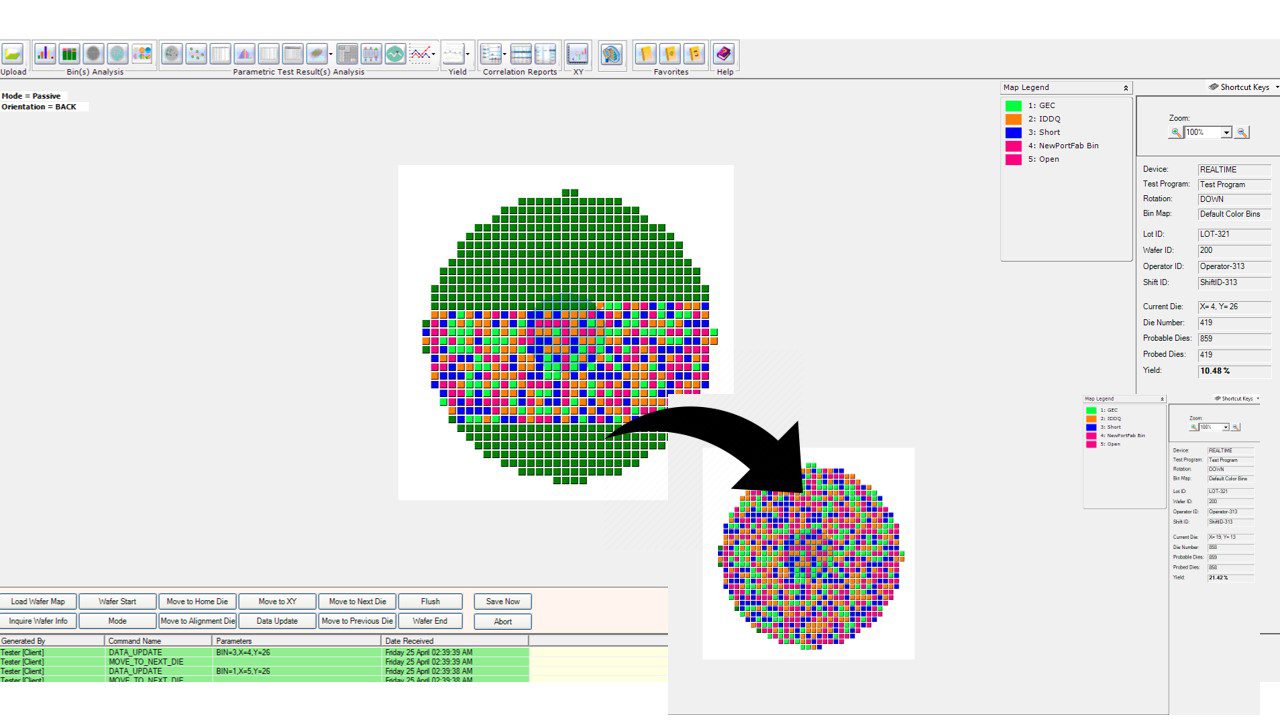

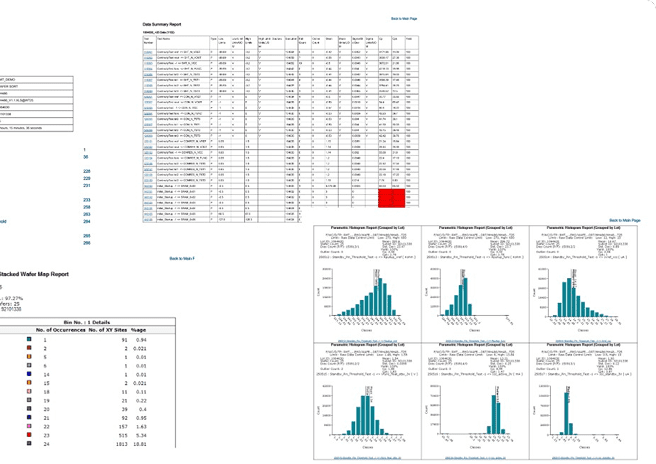

Make sense of the billions of data points collected across your entire design flow and maintain a pulse on your product’s yield in real-time. Discover how our powerful product suite can streamline your production process, alleviate engineering inefficiencies and drive quality at scale, helping you stay ahead of the competitive market.

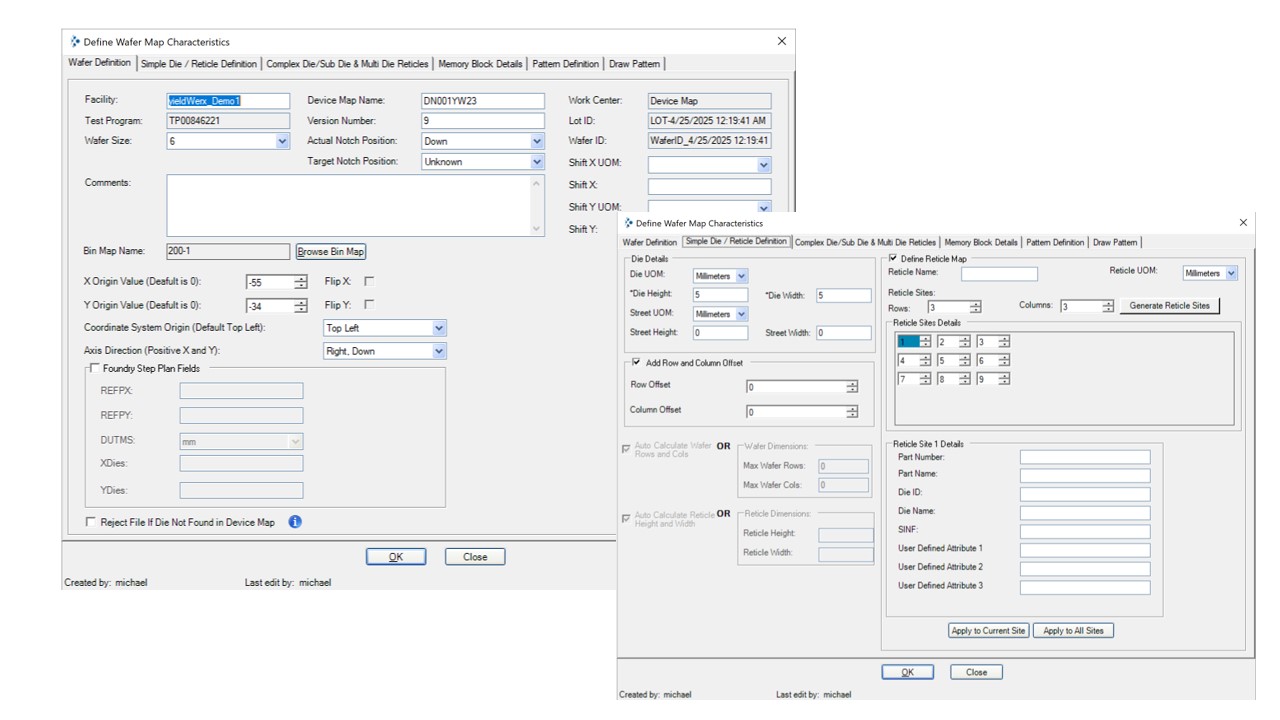

Our Unified Data Repository serves as the single source

of truth, consolidating data as and when necessary throughout the design, manufacturing, assembly, and test processes. This includes the ability to handle Process, Defect, Metrology/Critical Dimension data, images, and much more, extending to System Level Test, Board Assembly, and End Application data. This data can then be analyzed by Production Planners, Process Engineers, and others to determine the location of material, yield losses, planning for new lot starts, production capacity needs, and more.

Single source of truth encompassing data across the entire supply chain and product lifecycle

Unified Data Repository serving as the definite source of truth that is robust and scalable

3rd Party Integration allows bi-directional integration with MES, SAP, QMS, AMS and other applications

Process/Yield Analytics & Reporting - Over 300 ready-to-use reports, powerful BI

Automated Alerts and 24/7 health monitor

Securely accessible from any smart device anywhere around the world

Manage large volumes (up to petabytes) of data securely through a scalable infrastructure

Architecture that supports multiple databases to handle Engineering, Characterization, and Production data

Data warehousing solutions that can ingest data from multiple sources

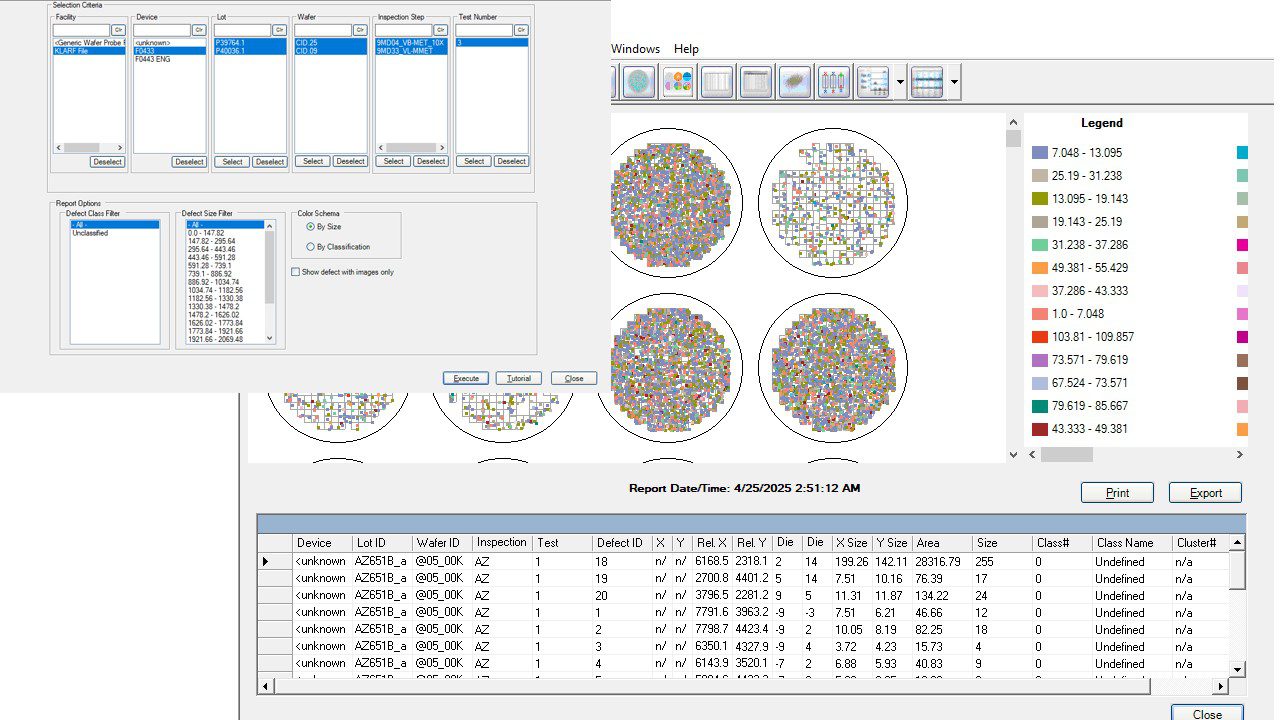

With yieldWerx’s AI/ML-assisted defect detection and rapid drill-down root cause knowledge graphs, IDMs can easily sift through billions of data points to pinpoint root causes quickly and accurately. This enables faster decision-making to interdict manufacturing processes and equipment. yieldWerx also supports Feed Forward and Feedback Closed Loops, which can then modify manufacturing recipes, probing patterns, test programs, or test limits, to name a few.

Root Cause Knowledge Graphs enable rapid AI-assisted defect analysis

Defect Management uses image guided correlation analysis to find defects quickly and accurately

Supports Feed Forward and Feedback Closed Loops

Our solution helps minimize yield loss through clear yield rate analytics, reducing scrap, rework, and retests to reduce test time and other causes of yield loss.

Custom Limits Manager for accurate what-if analysis allowing for flexible rebins without retests

Yield Prediction enhances forecasting accuracy for escape prevention

Wafer Bank Scrapping allows for die level selection for scrap and downgrade

Discover the yieldWerx difference and revolutionize your semiconductor operations. Schedule a demo today!