Overcome the challenges of complex and high precision product requirements compounded by variations in manufacturing and environmental factors.

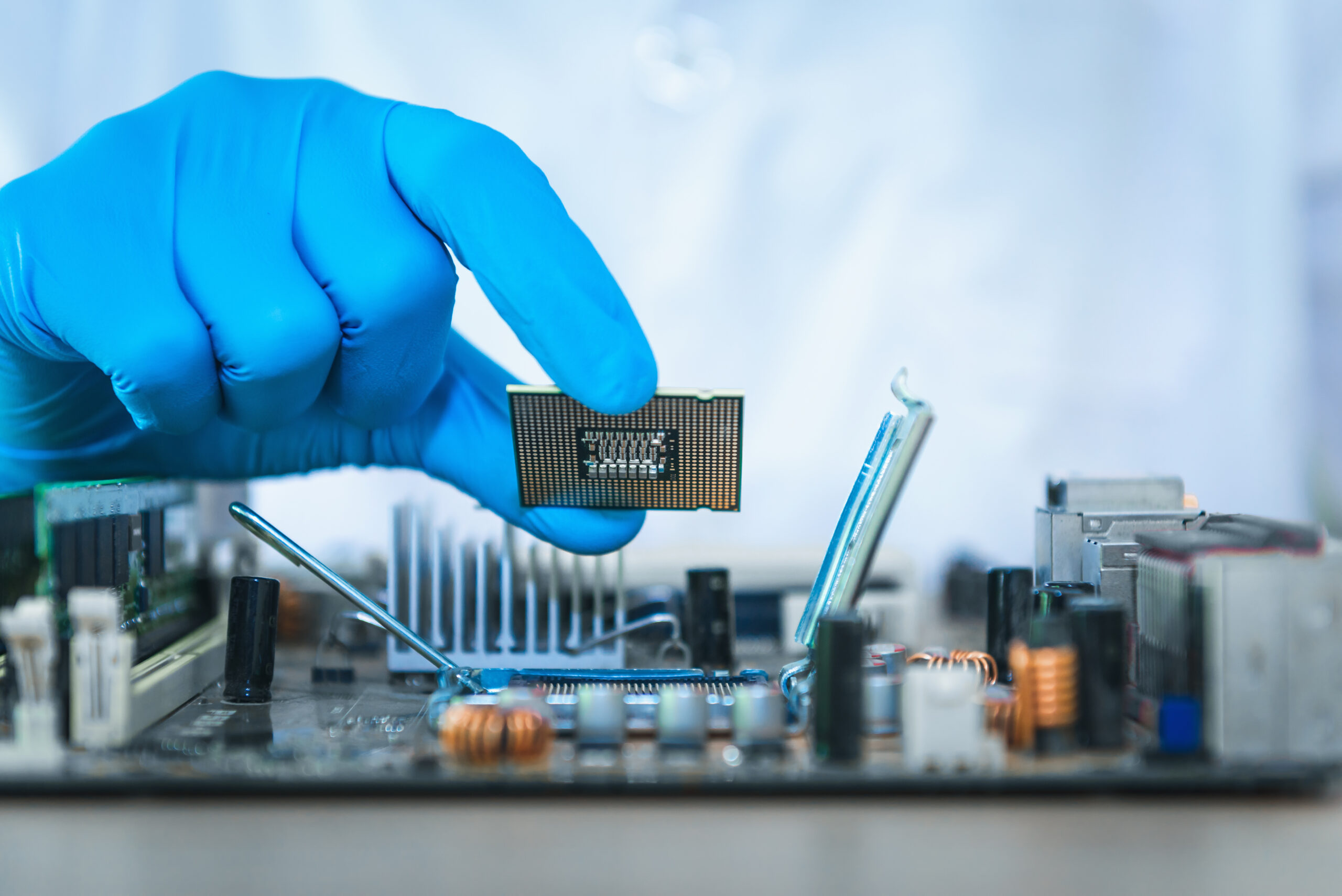

The designs of ASIC, MSP, and Analog devices are inherently complex, due to their high sensitivity to manufacturing variations and custom logic. These industries require precise process control, as even small deviations can significantly impact device performance. Analog devices, in particular, are highly susceptible to process variability such as voltage flunctuations, resistor tolerance, and capacitor variance. Aging and environmental factors can also lead to yield loss and degraded performance. Testing is more complex, as it involves continuous variables and demands high precision validation techniques. The need for customizations for integrating both analog and digital components in mixed-signal systems also adds layers of complexity to yield optimization.

Mixed signal systems and custom logic adds levels of complextiy to yield optimziation

Components used in varied external environments impact performance

Environmental factors such as aging and degradation can lead to yield loss

Discover the yieldwWerx difference and revolutionize your semiconductor operations. Schedule a demo today!