Real-Time Process Controls

24/7 process monitoring

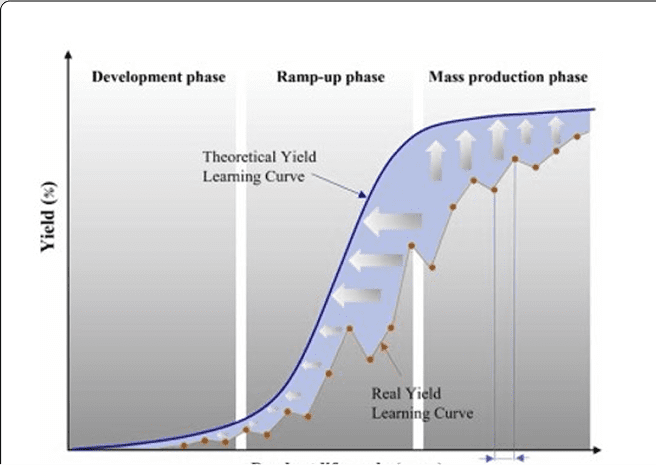

yieldWerx enables a stable transition from NPI to Volume Ramp, fine-tuning production parameters to ensure quality stays consistent as production increases.

As production increases in volume, this critical ramp up requires a dynamic approach to not only maximizing yield but also optimizing manufacturing processes to improve yield and stabilize the supply chain.

yieldWerx enables products in the volume ramp phase to scale efficiently and effectively by enabling real-time monitoring, immediate failure detection, and rapid feedback loops that enable fine-tuning and adjustments.

Discover the yieldwWerx difference and revolutionize your semiconductor operations. Schedule a demo today!