Leverage yieldWerx’s advanced visualizations for complete data flow visibility, early detection, and maximized yield. We enable Fabless companies to spend less time on finding and fixing defects and focus more energy on product design and innovation with our advanced AI-assisted root cause analysis, early fault detection, advanced PAT and SPC capabilities, and 24/7 production monitoring.

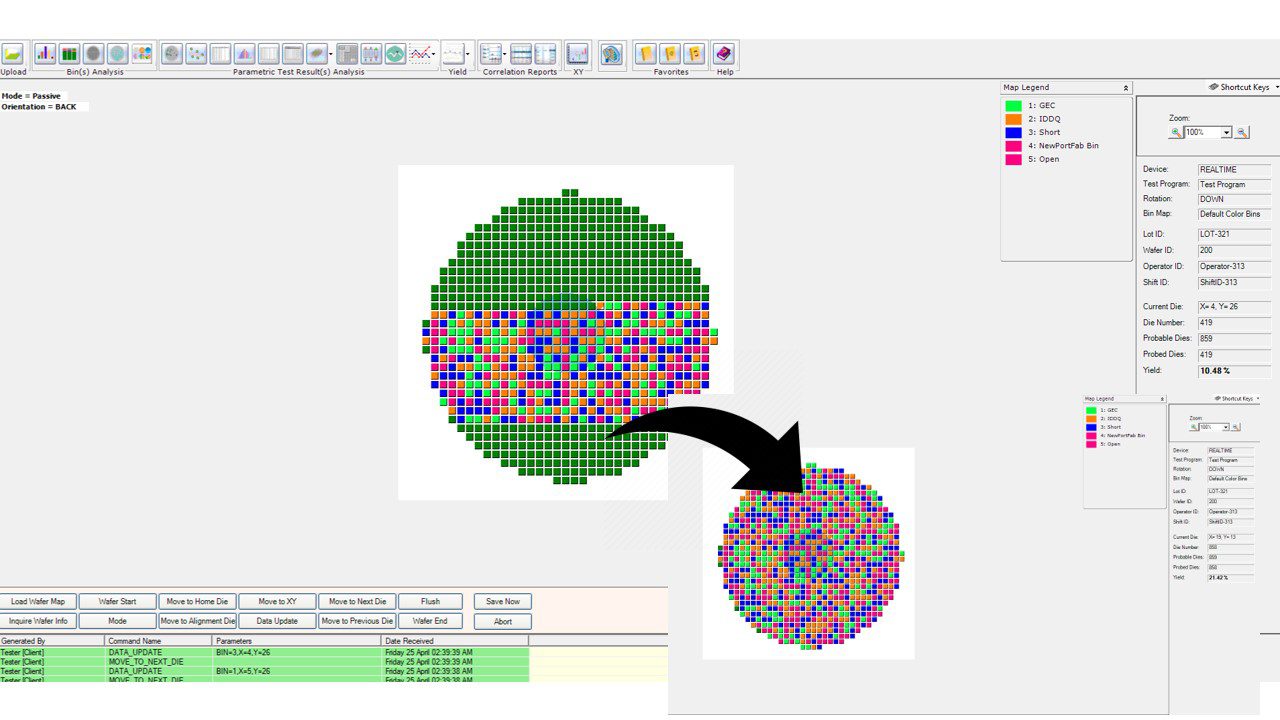

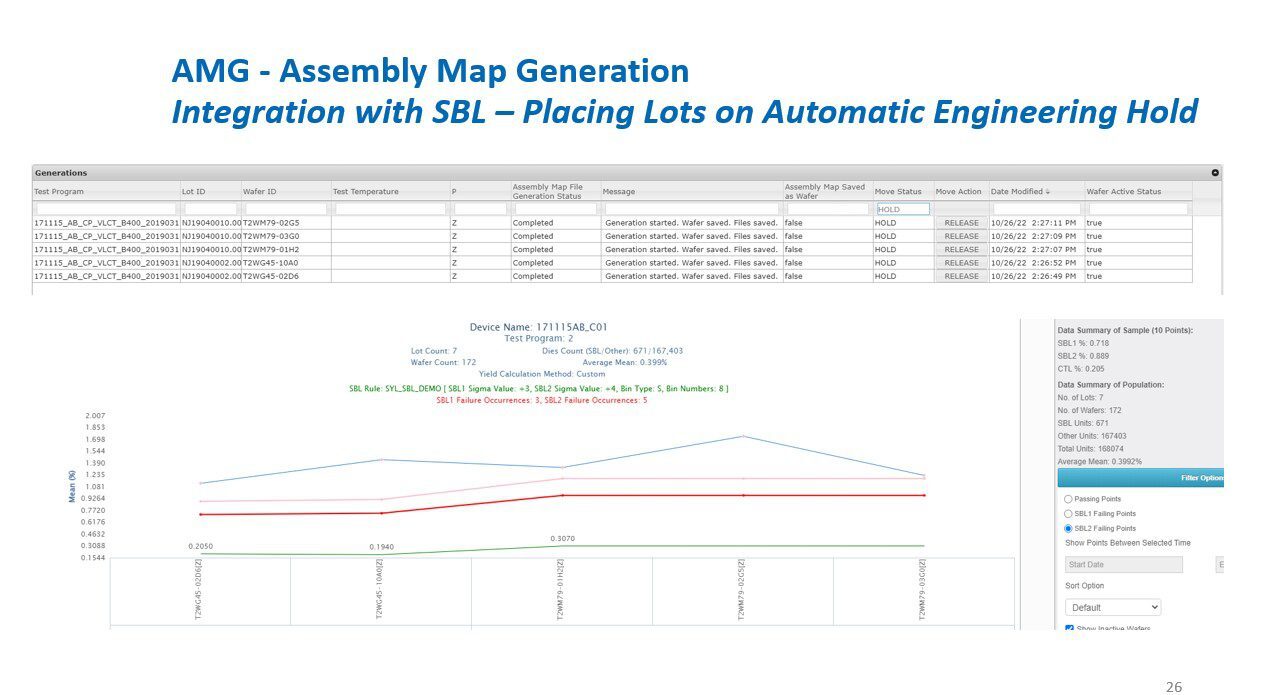

Fabless customers can use yieldWerx to manage data flow bidirectionally from foundries, OSATs, and supply chain partners much more efficiently, as close to real-time as possible. This enables them to make near real-time decisions that go beyond just test data and yield analysis.

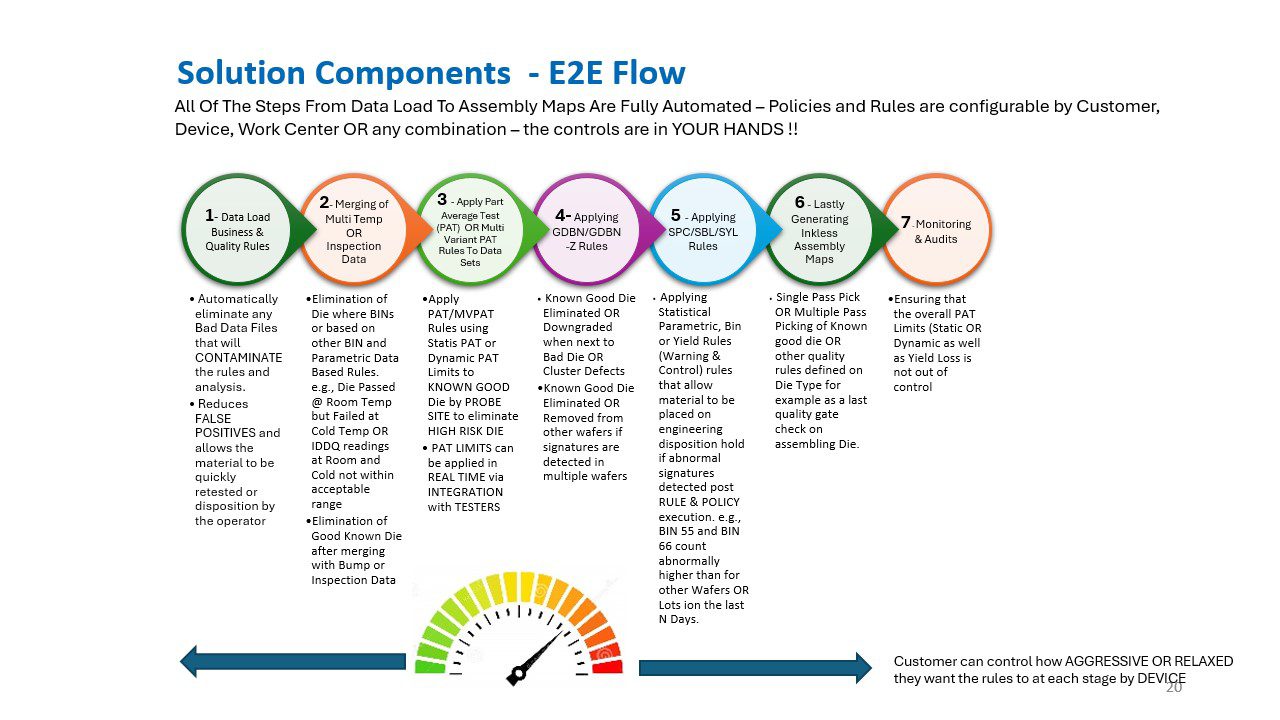

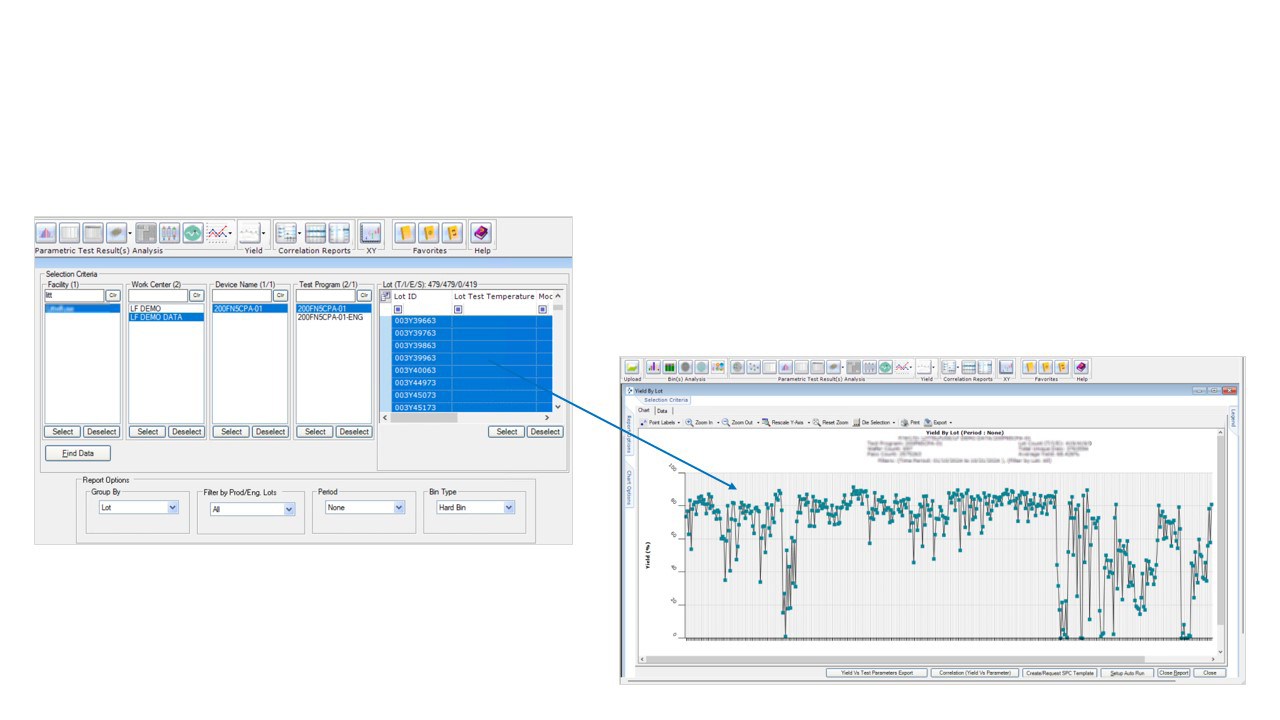

Customers can access fully interactive analytics and data quality health monitoring for quick feedback loops and timely interventions, using simple drag-and-drop functionality. The Statistical Process Control (SPC) and Fab-to-Assembly/Test correlation enable customers to receive early signals when process drifts start to occur, as well as to correlate low yield at CPOR FT and conduct Root Cause Analysis (RCA).

Process/Yield Analytics & Reporting - Over 300 ready-to-use reports, powerful BI

Automated Alerts and 24/7 health monitoring

SPC and Fab-to Assembly/Test correlations for early process drift detection and RCA

Access real-time metrics for yield, performance, analyze data, and generate Design of Experiments (DOEs) to address quality issues early, as well as impact material that is still in WIP.

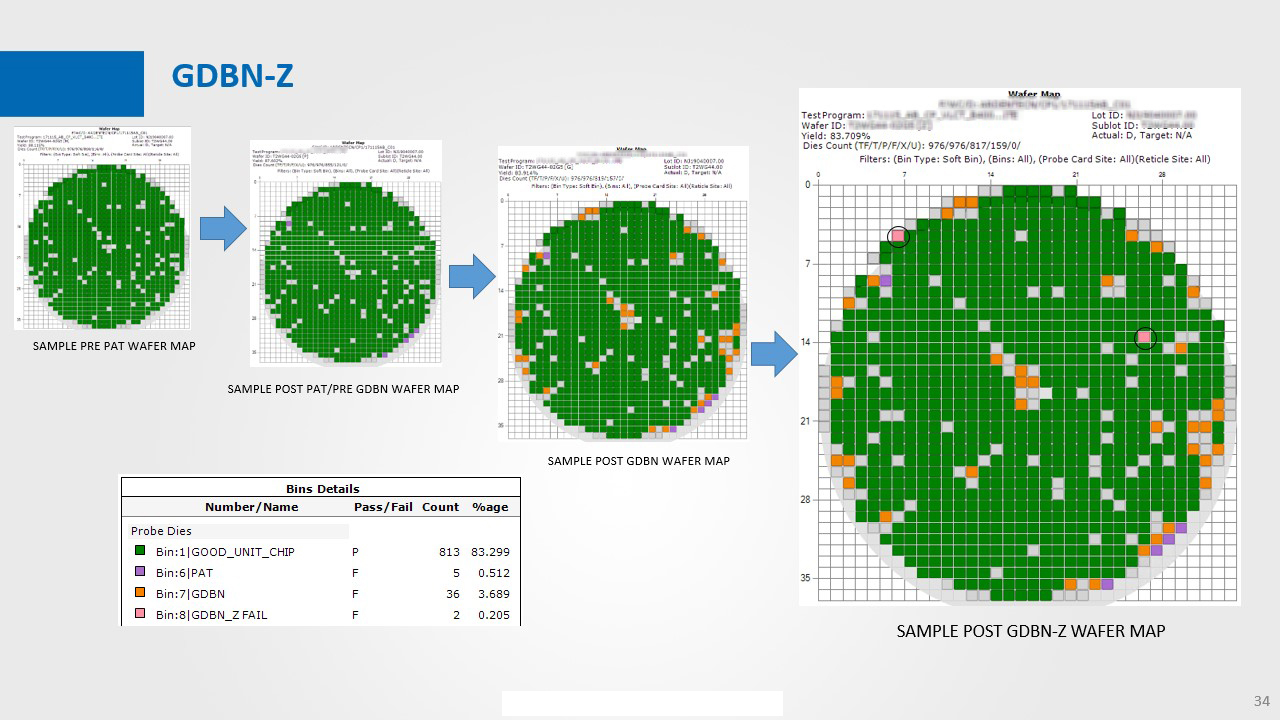

Quality Control & Risk Containment provides advanced PAT, SPC, and outlier detection

Custom Limits Manager for accurate what-if analysis allowing for flexible rebins without retests

Generates DOEs to address quality early while material is in work in process (WIP)

Fabless companies can access data with complete

transparency across the supply chain, from design to packaging and final tests, allowing for thorough and fast root cause traceability.

Automated Analysis & Dispositioning automates lights-out data ingestion, cleansing, and enrichment

3rd Party Integration allows bi-directional integration with MES, SAP, QMS, AMS and other applications

Robust and scalable data solution with cloud and

on-premise solutions

With yieldWerx’s AI-assisted predictive analytics, Fabless

companies can proactively identify process variations through pattern recognition and advanced statistical algorithms, detecting potential yield loss before manufacturing begins.

Yield Prediction enhances forecasting accuracy for escape prevention

AI Powered Commonality Analysis isolates systemic causes of yield loss

Our solution and lot genealogy capability allow robust data

comparison across multiple production facilities, enabling fabless companies to quickly and accurately track yield analytics and metrics across lots, product families, and multiple manufacturing sites.

Robust comparison across multiple production facilities

Lot Genealogy for bi-directional traceability from lot to wafer to die level

Automated Lot Disposition utilizes AI algorithms to predict commonality correlations

Discover the yieldWerx difference and revolutionize your semiconductor operations. Schedule a demo today!