Role of Semiconductor Yield Management System at High Volume Production

Semiconductor wafer fabrication plant is one of the most capital intensive unit with a production cycle of more than 6 weeks. Typically, a modern state of the art process fabrication plant costs more than $3 billion these days. In order to justify this much of an investment and to have a positive bottom line it becomes inevitable for the production units to have consistently higher yields and throughput.

Semiconductor wafer fabrication plant is one of the most capital intensive unit with a production cycle of more than 6 weeks. Typically, a modern state of the art process fabrication plant costs more than $3 billion these days. In order to justify this much of an investment and to have a positive bottom line it becomes inevitable for the production units to have consistently higher yields and throughput.

The pressure is further fueled by the stiff competition in the industry and the stringent quality and reliability requirements from the customers. The widespread adoption of IOT devices in our daily lives fueled with the powerful mobile phone penetration has increased the production volumes on one hand while on the other end has made the semiconductor wafer fabrication process increasingly complex. With billions of parts being shipped by the semiconductor manufacturers of high dependencies, the customers are demanding defect per billion instead of defect per million quality standards.

In such a premise, it becomes necessary to have a fully functional yield management system (YMS) deployed at the heart of semiconductor wafer fabrication operations that not only manages issues affecting operations but also improves yield and helps in ramping product faster to market, giving a competitive edge of higher quality and reliability of products being shipped to end customers.

So how exactly does a yield management system help in managing yields at high volume production?

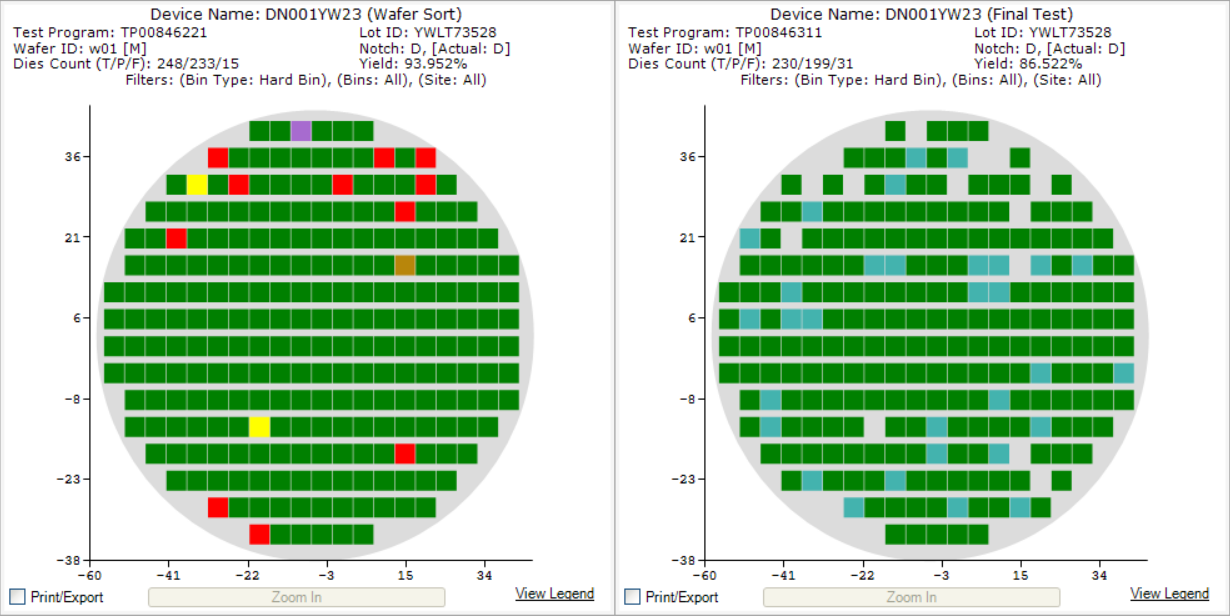

YMS starts with providing advanced real-time data management features that stores the data coming out of various nodes of the wafer fabrication process in a central database. The data is then analyzed by the powerful statistical tools of the YMS that generates different types of reports related to defect and yield management. This intuitive and visual representation of the test data provides a unified view of the heath of the operations throughout the supply chain making it easier to pin-point the issues affecting yield and monitor the operations. The users are able to set alarms that are generated when quality standards are violated and flags are raised. In most case, the yield management system is integrated with the manufacturing execution system (MES) which gives the capability to stop or hold the production lines automatically in case of outlier detection.

This early detection of low yielding wafers or equipment failures allows the engineers to resolve issues in a timely manner while maintaining the requisite quality and reliability standards. This steep yield ramp translates into a faster track to high batch yield that further translates into higher production cycles, increased equipment utilization and shipping products to market faster than the competitor thereby positively impacting the bottom-line and giving a competitive advantage to the semiconductor manufacturer.

One of our customers, Azoteq has reported yields to 98% at the final test stage of wafer fabrication process along with added advantage of quick decision making because of powerful data management capabilities of yieldWerx that has resulted in faster ramp-ups and lower test costs. If you are interested in increasing your production yield or to manage your operations at high yielding lots without compromising on quality and reliability, contact us today and schedule a demo. Our sales and technical team will get in touch with you to demonstrate the product offerings. You can schedule a live demo with them.

Recent Posts

- AI-Powered PAT: A New Era of Smarter Manufacturing

- KLARF File Format: Enhancing Semiconductor Yield Analysis with yieldWerx

- The 2022 CHIPS Act May Be Repealed: What Does This Mean for You?

- End-to-end Semiconductor Data Analytics and Traceability Solutions For Multi-Chip Packages

- Semiconductor Traceability Using Lot Genealogy For Multi-Chip Modules