Synopsis:

Ability to merge data from different data sources, and test conditions via user-definable rules and policies. Ability to perform what-if analysis. Can also create complex rules based on Bin, Bin & Parametric and define new Parameters generated Post Test.

Description:

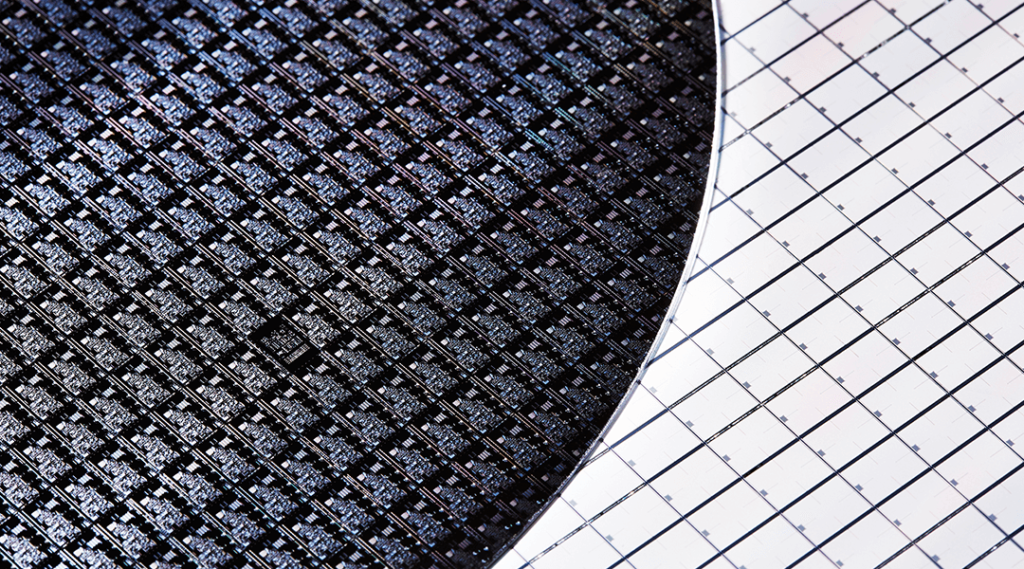

yieldWerx's Smart Wafer Merge module provides customers a sophisticated level of wafer-level yield management based on multiple sources of wafer-related data. Consequently, merging data from these multiple sources results in a final wafer map and associated test data set. With this data in hand, engineers can effortlessly develop rules and calculate virtual test values, upon which policies for decisions on die or wafer actions are made.

Prior to automating the rules, they can validate them based upon the historical data. Then it’s hands-off and onto the next quality and yield issue for them to decipher. With automation, if something changes, reports that monitor the results can be accessed by engineers.

For NPI and defense/aerospace devices, engineers run wafer tests through three distinct temps (cold, ambient, hot). Each temperature yields a unique wafer map for bins or an IDDQ measurement. Consequently, an engineer can combine the wafer maps to determine pass/fail die or downgrade parts based on a change of IDDQ values between the various temperatures. As a result, engineers can create a policy to fail a die if a series of rules are met. For instance, in the previous scenario, they could decide that even if the die is considered a Good bin the die could be marked fail based upon a calculated value of the three IDDQ measurements.

Where applied:

- Post Wafer test

Engineering Roles Impacted:

- Product Engineer

- Process Engineers

- Quality Engineer

- Characterization Engineer

Dependencies on other modules:

- External Data Source Integration

- Assembly Map Generation

- SPC

- Outlier Detection