yieldWerx lets you create and save wafer maps that can be downloaded to your probers through its SmartProbeTM tool. It gives you production control over your prober test cells and collects and monitors your probing data in real-time to detect and address issues quickly.

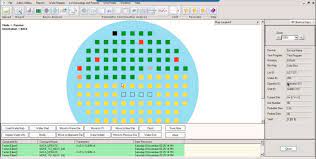

Wafer Map Layout

With this wafer mapping software tool, you can create new or edit your existing wafer maps. Optimize your probe card layout and probe route. The wafer map definition file can then be downloaded to your prober to be used in conjunction with the Wafer Probe Test Cell Controller. With the help of this wafer map software, we can define you.

- Probe Card Layout

- Non-testable Die

- Edge Die

- Reference Die

- Plug Bars

- Test Structures

- Alignment Die

- Center Die

- Define Custom Zones

Smart Probe is a fully functional Wafer Probe Test Cell Controller with advanced multi-step wafer probe support. Many rules can be defined to ensure you’re testing only the die you want. The system can handle mapping and probing of devices which require the front and back of the wafer to be probed. It also collects; displays and analyses test binning data. The data is saved to the database in real-time so there is no data loss in the event of test equipment failure. Smart probe enables engineers to partially probe, unload and start probing where you left off on another tester which in turn can also help in wafer probe testing.

yieldWerx provides a powerful wafer mapping system that lets the user to collect, load, read and create wafer maps in real-time from the customer’s semiconductor test data. The supreme visualization offered by yieldWerx wafer mapping tool lets the user to analyze and understand the health of the wafers quickly in real-time. This graphical mapping of semiconductor wafers helps the engineers to slice and dice the wafer and analyze the data and identify issues that can affect the quality negatively.

The robust architecture of yieldWerx Enterprise application allows the user to create wafer maps from a set of different formats. Some of our customers are creating wafer map using excel files containing their test data from various nodes of their fragmented global supply chain. Our other customers have successfully analyzed the same where they were storing the test data for wafer mapping in ‘csv’ based file. This capability of yieldWerx that allows the support of a wide range of data formats is perceived very high by the customers as it helps their engineers to save time on loading data and work on high value activities like root cause analysis. This extra engineering hours spent on the failure analysis and yield analysis directly impacts the bottom line of the company.