Zero Defect Certification with yieldWerx's Part Average Testing Solutions

Ensure automotive certification with device integrity using our Part Average Testing Module.

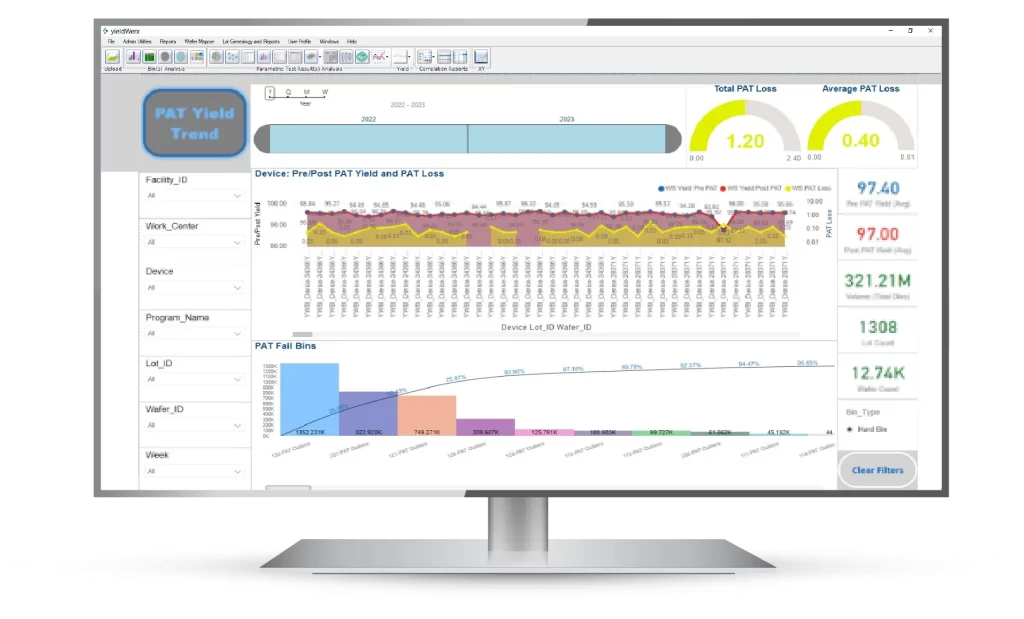

Balancing Quality and Yield with Part Average Testing Insights

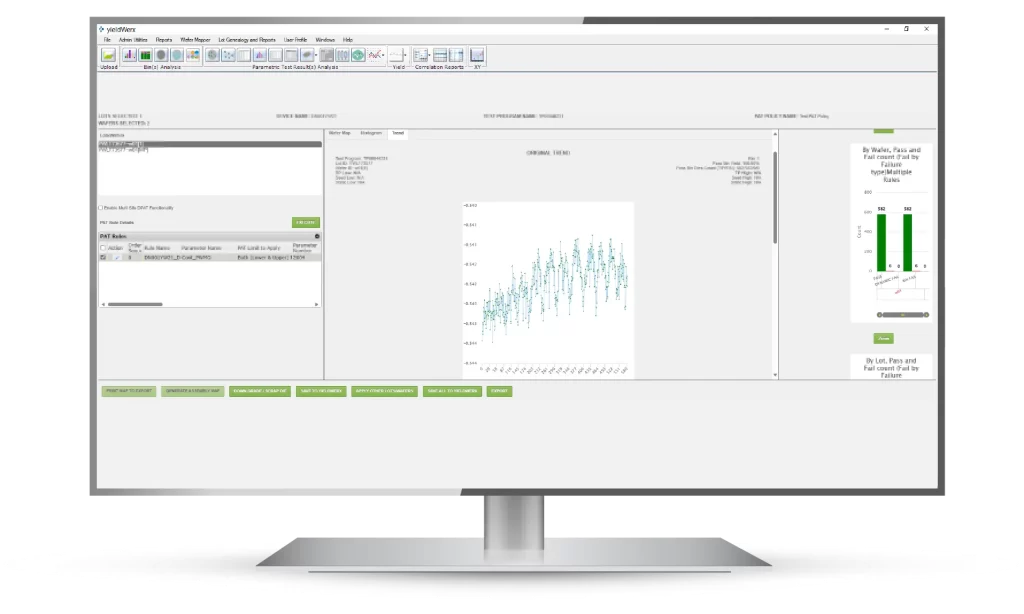

yieldWerx's Part Average Testing combines Static and Dynamic PAT Limits to ensure optimal quality with minimized yield loss, enhancing efficiency and satisfaction with real-time alerts and customizable rules.

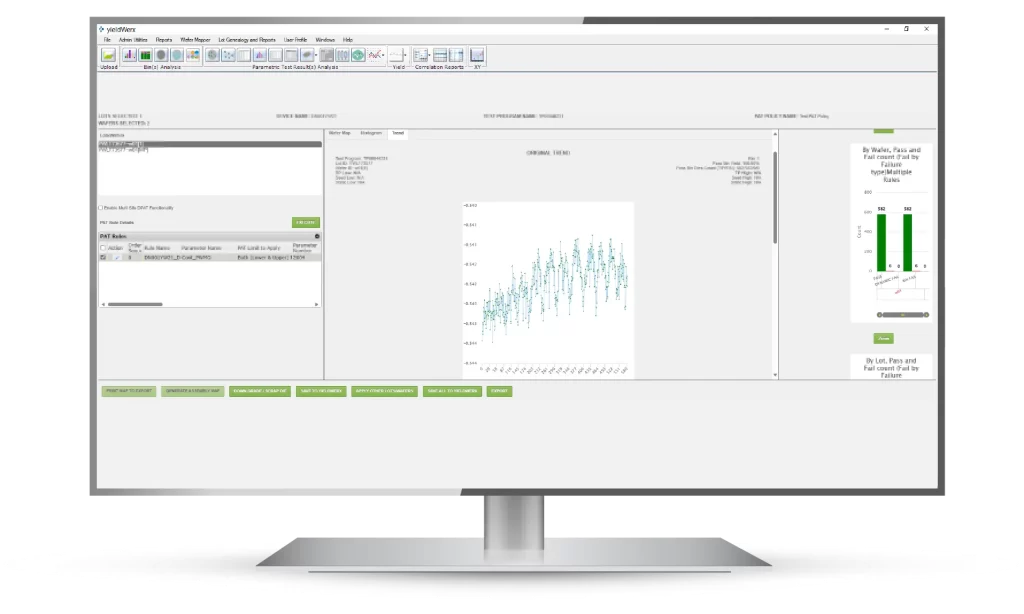

Strategic Semiconductor Testing with Dynamic PAT and Static PAT

For DPAT

yieldWerx's Dynamic PAT ensures top-quality semiconductors using real-time recalibration to minimize field failures.

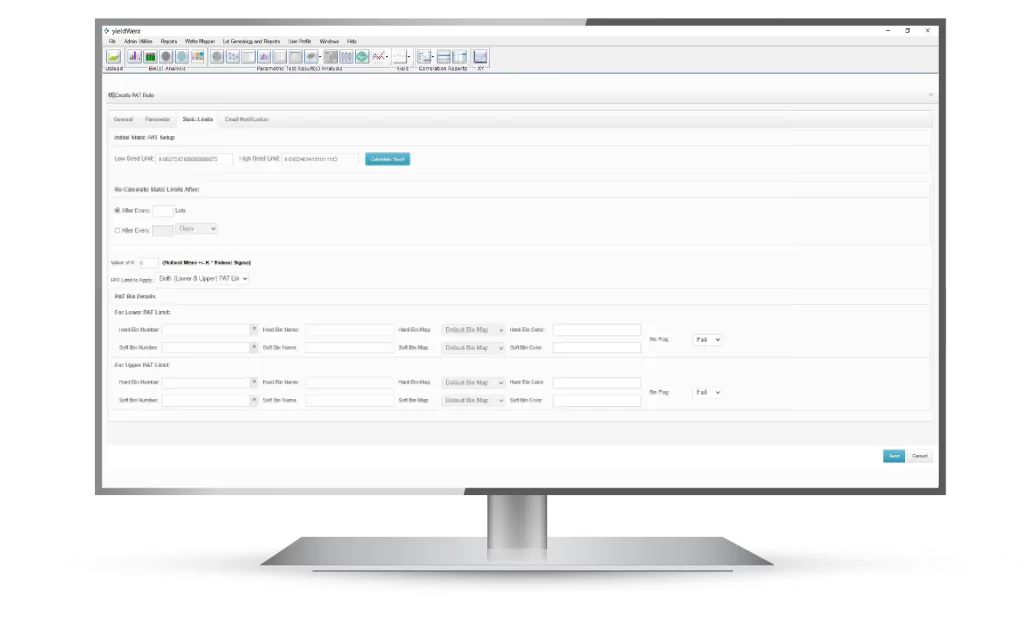

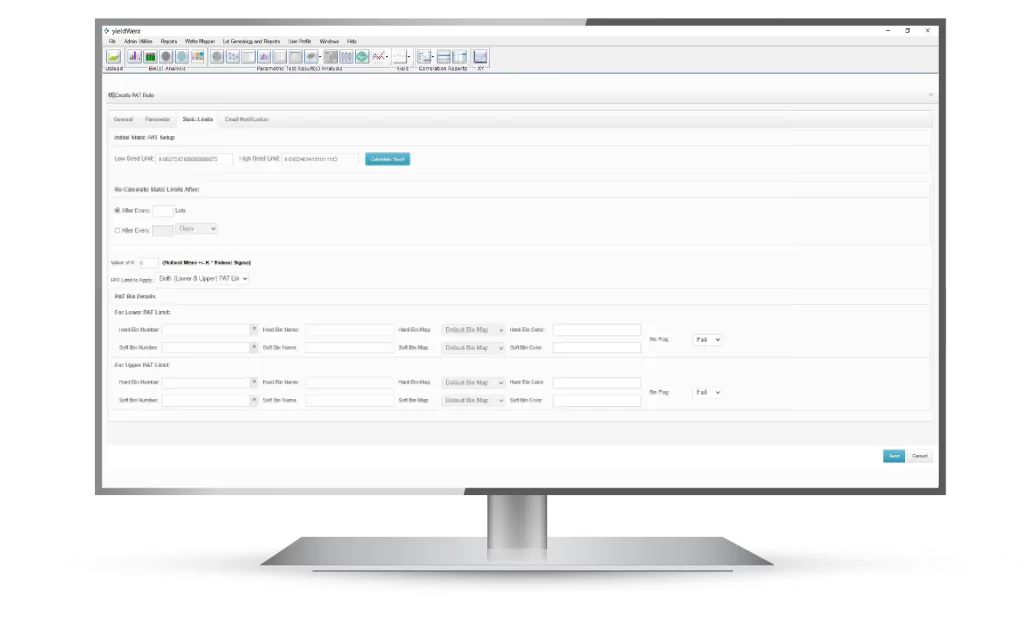

For SPAT

yieldWerx's Static PAT uses historical data to set test limits, cutting return rates and boosting reliability.

Key Features of Part Average Testing

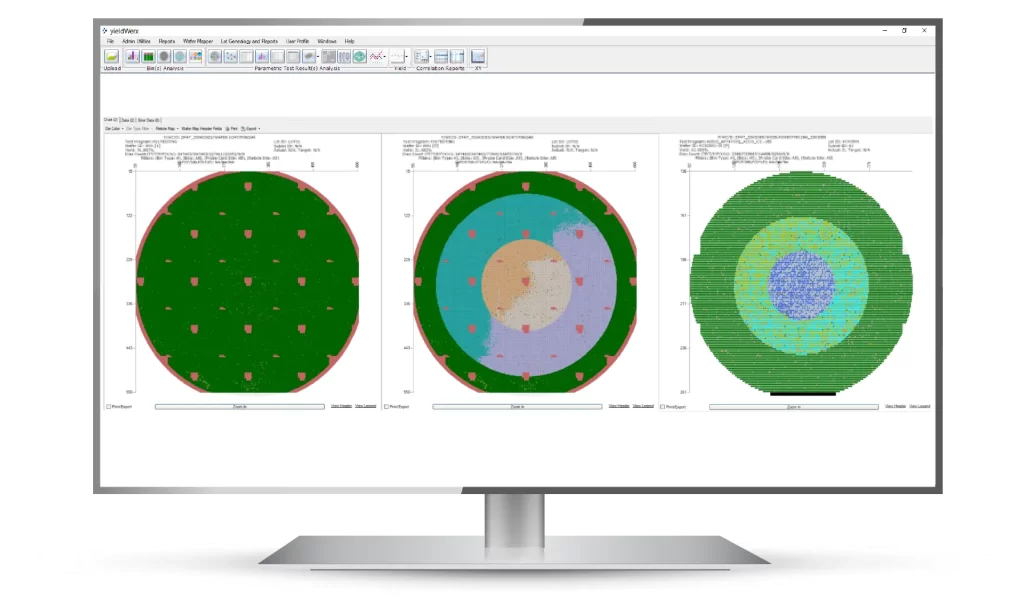

Analyze and Adapt

Analysis of Wafer Sort/Final Test Data sets real-time PAT limits, adapting to dynamic conditions.

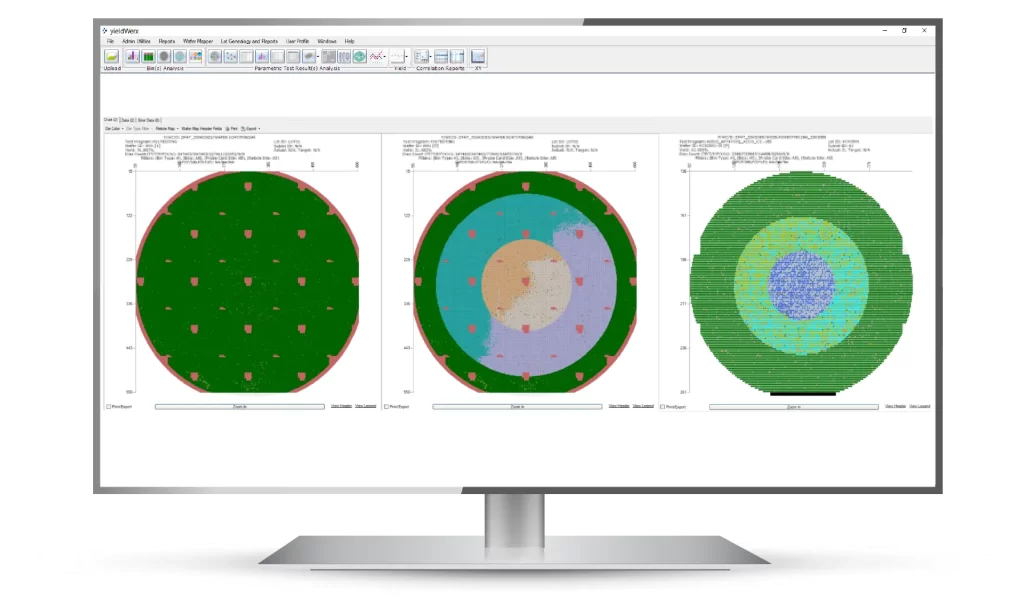

Optimize Outlier Detection

Utilize MVPAT with GDBN/Z-Axis for precise outlier detection and device reliability.

Enhance Testing Flexibility

Choose between Static or Dynamic PAT to optimize test limits for diverse production scenarios.

Customization, Integration, and Real-Time Insights with yieldWerx PAT

Customize with Precision

Set custom PAT rules and DPAT sample sizes for specific test needs and operational challenges.

Integrate for Efficiency:

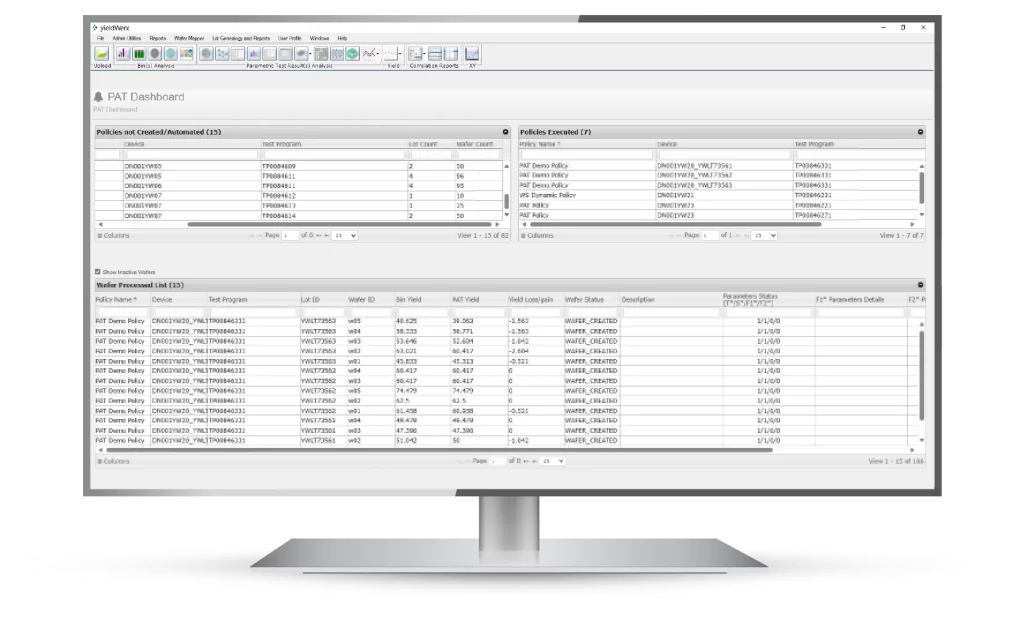

Use yieldWerx to integrate the PAT module with MES/Shop-floor control systems, and ATE systems.

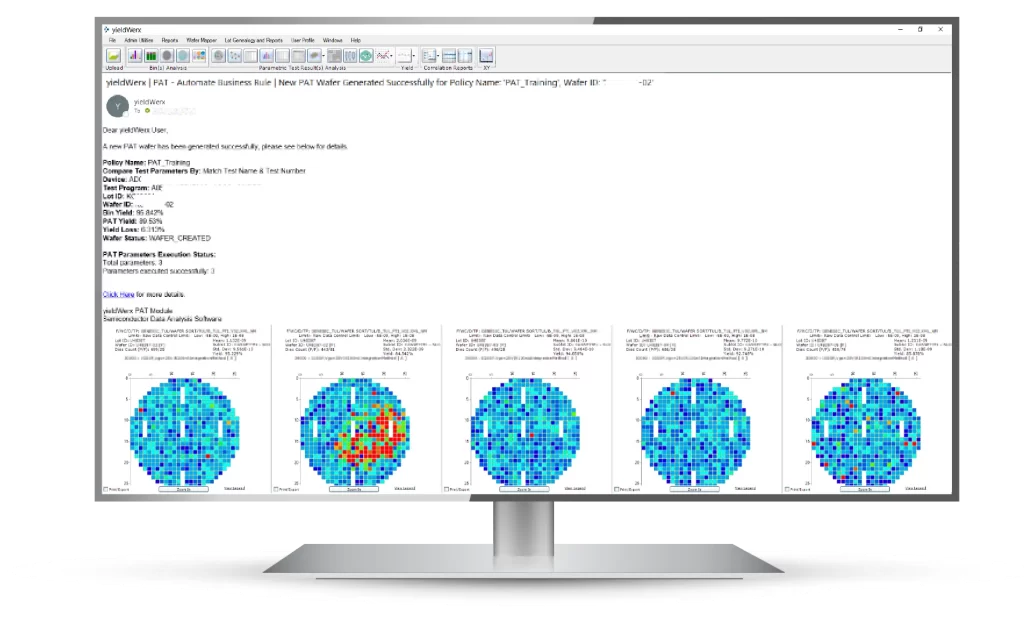

Stay Informed in Real-Time

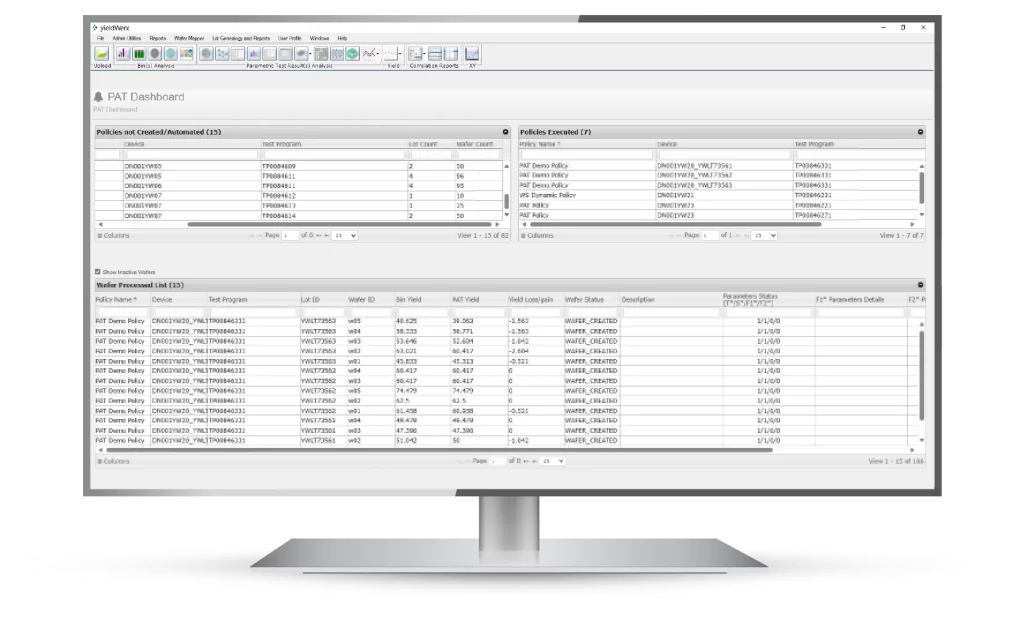

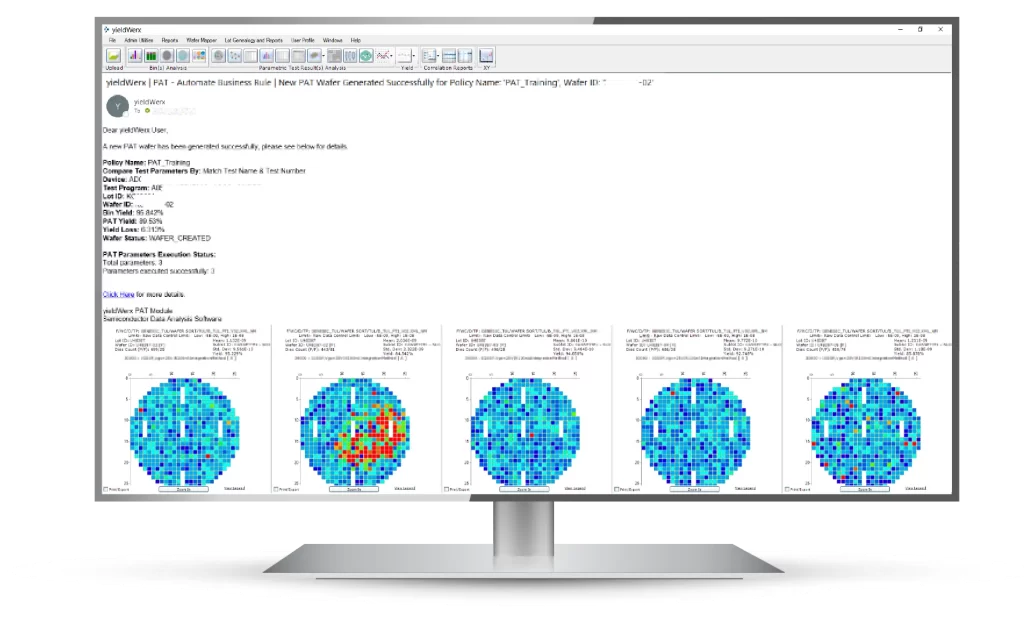

Receive instant alerts on testing anomalies for quick, informed quality control decision making.

Achieving Zero Defects in Semiconductors through yieldWerx’s Real-Time PAT

Assured Quality and Reliability

yieldWerx guarantees the shipment of high-quality, reliable devices, significantly reducing zero-defect concerns for customers.

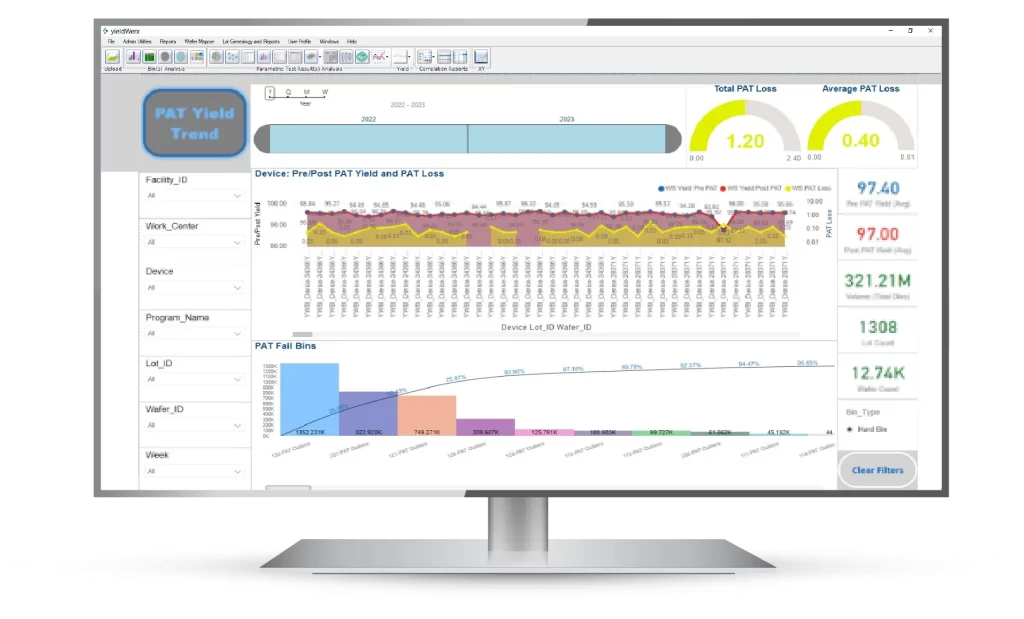

Operational Efficiency and Cost Savings

Implement early detection of potential failures, optimize process improvements, and reduce RMAs, fostering cost-effective operations.

Proactive Monitoring and Customization

Benefit from real-time monitoring, automatic alerts, and the ability to create custom rules in PAT for predictive and immediate responses to production anomalies.

Zero Defect Certification with yieldWerx's Part Average Testing Solutions

Ensure automotive certification with device integrity using our Part Average Testing Module.

Balancing Quality and Yield with Part Average Testing Insights

yieldWerx's Part Average Testing combines Static and Dynamic PAT Limits to ensure optimal quality with minimized yield loss, enhancing efficiency and satisfaction with real-time alerts and customizable rules.

Strategic Semiconductor Testing with Dynamic PAT and Static PAT

For DPAT

yieldWerx's Dynamic PAT ensures top-quality semiconductors using real-time recalibration to minimize field failures.

For SPAT

yieldWerx's Static PAT uses historical data to set test limits, cutting return rates and boosting reliability.

Key Features of Part Average Testing

Analyze and Adapt

Analysis of Wafer Sort/Final Test Data sets real-time PAT limits, adapting to dynamic conditions.

Optimize Outlier Detection

Utilize MVPAT with GDBN/Z-Axis for precise outlier detection and device reliability.

Enhance Testing Flexibility

Choose between Static or Dynamic PAT to optimize test limits for diverse production scenarios.

Customization, Integration, and Real-Time Insights with yieldWerx PAT

Customize with Precision

Set custom PAT rules and DPAT sample sizes for specific test needs and operational challenges.

Integrate for Efficiency:

Use yieldWerx to integrate the PAT module with MES/Shop-floor control systems, and ATE systems.

Stay Informed in Real-Time

Receive instant alerts on testing anomalies for quick, informed quality control decision making.

Achieving Zero Defects in Semiconductors through yieldWerx’s Real-Time PAT

Assured Quality and Reliability

yieldWerx guarantees the shipment of high-quality, reliable devices, significantly reducing zero-defect concerns for customers.

Operational Efficiency and Cost Savings

Implement early detection of potential failures, optimize process improvements, and reduce RMAs, fostering cost-effective operations.

Proactive Monitoring and Customization

Benefit from real-time monitoring, automatic alerts, and the ability to create custom rules in PAT for predictive and immediate responses to production anomalies.

Why Choose yieldWerx

Self Service Capability for Report Creation

Service Capability for Report Creation offers flexibility and control to customize reports for your semiconductor needs.

100+ Management/SCM/Planing Widgets

With 100+ Management/SCM/Planning Widgets, enhance management, supply chain, and planning for improved productivity.

Engineering & Quality Control Widgets

Engineering & Quality Control Widgets offer specialized tools for advanced product development and stringent quality control.

Scalable Data Solutions

Scalable Data Solutions partnered with giants like Amazon Web Services and Microsoft Azure for cloud-hosted solutions.

Product Engineer

Equip Product Engineers with streamlined test program management and improved design and manufacturing processes

Quality Engineer

Quality Engineers receive deviation alerts, and tools for effective problem identification and management throughout a product's lifecycle.

Yield Enhancement Engineer

Yield Enhancement Engineers leverage data analytics for actionable insights, facilitating cross-group communication to boost yield.

Ready to Redefine Yield Calculation?

Join the leaders in semiconductor manufacturing who trust yieldWerx and our die per wafer calculation module. Start your journey towards data-driven excellence today. Our team is ready to support you every step of the way.