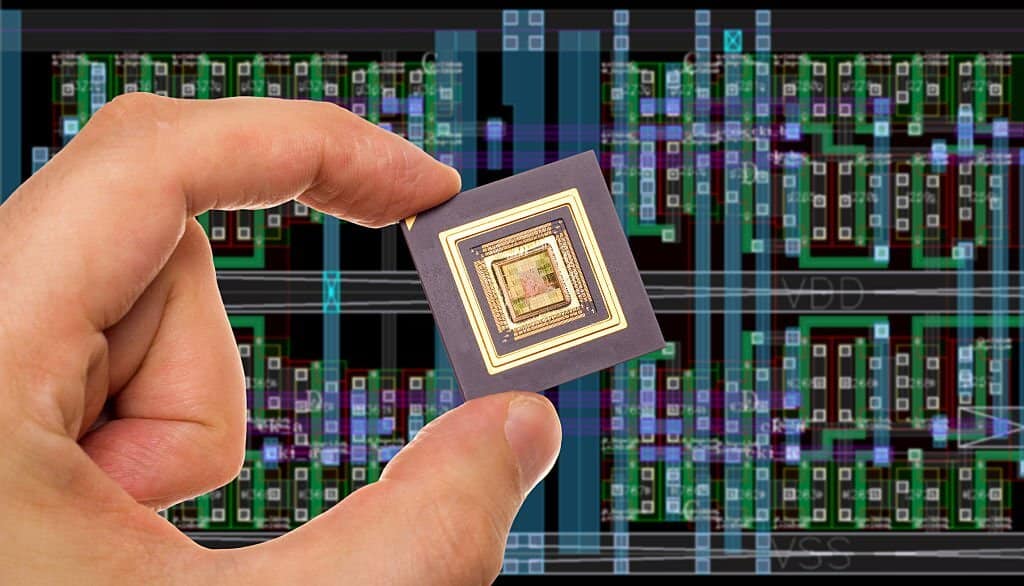

Ultimate Yield Analytics Platform

yieldWerx enhances reliability, streamlines testing processes, and accelerates time-to-market across entire fast-paced consumer electronics sector, where product life cycles are typically only two years.

Elevate Your Manufacturing Cycle

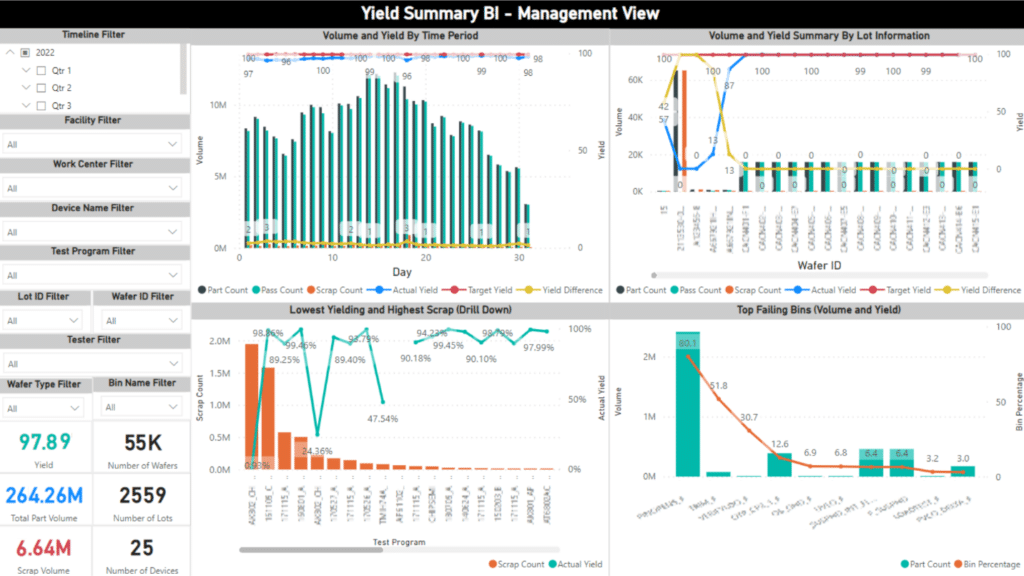

Quick Issue Identification:

Quickly address yield issues during new product introductions and re-spins of silicon designs.

Data-Driven Decision Making:

Utilize split lot data to evaluate silicon over a process range and detect yield surprises early in manufacturing.

Optimized Supply Chain:

Accurate yield numbers facilitate efficient planning for wafer starts and packaging orders, ensuring smooth supply chain operations.

Facilitating the Electronics Sector

Bulk Data Management:

Analyze high volume of data from different sources efficiently and seamlessly through yieldWerx.

Improving Test Time:

Analyze testing procedures and processes to identify and eliminate redundancies, thereby reducing associated test times and ultimately saving costs

Yield Pattern Visualization:

Quickly stack and analyze hundreds of wafers simultaneously and quickly to reveal hidden actionable insights

Streamline Site Operations:

Optimize yield across multiple testing sites with comprehensive site and tester-based analysis tools.

Customized Integrations

Modular:

Tailored solutions that evolve with sector needs and are easily scalable on either On-Prem, Cloud or Hybrid infrastructure.

Craft Custom Solutions:

Provide end-to-end personalized yield management solutions catering specifically to the needs of the electronics industry.

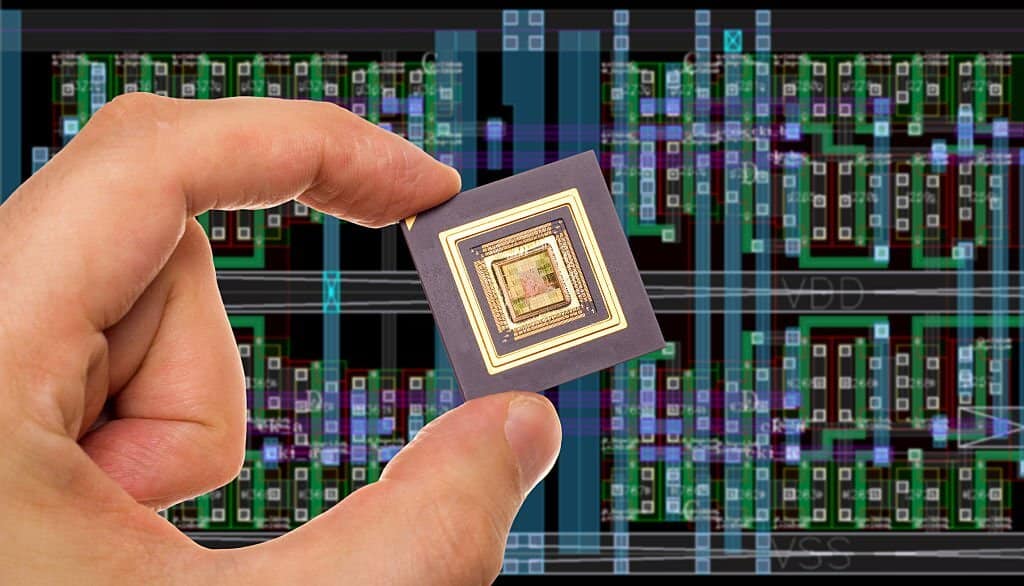

Ultimate Yield Analytics Platform

yieldWerx enhances reliability, streamlines testing processes, and accelerates time-to-market across entire fast-paced consumer electronics sector, where product life cycles are typically only two years.

Elevate Your Manufacturing Cycle

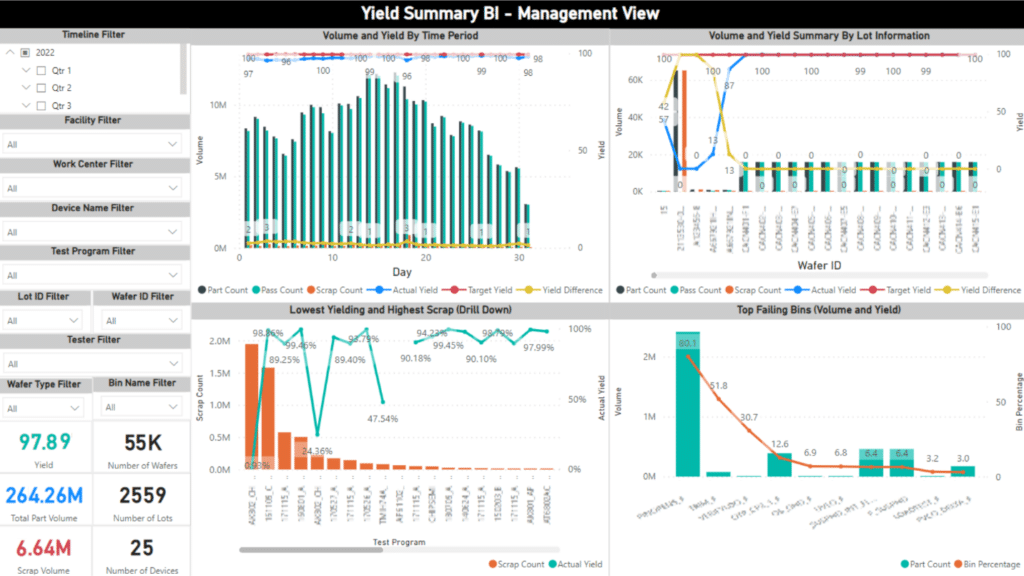

Quick Issue Identification:

Quickly address yield issues during new product introductions and re-spins of silicon designs.

Data-Driven Decision Making:

Utilize split lot data to evaluate silicon over a process range and detect yield surprises early in manufacturing.

Optimized Supply Chain:

Accurate yield numbers facilitate efficient planning for wafer starts and packaging orders, ensuring smooth supply chain operations.

Facilitating the Electronics Sector

Bulk Data Management:

Analyze high volume of data from different sources efficiently and seamlessly through yieldWerx.

Improving Test Time:

Analyze testing procedures and processes to identify and eliminate redundancies, thereby reducing associated test times and ultimately saving costs

Yield Pattern Visualization:

Quickly stack and analyze hundreds of wafers simultaneously and quickly to reveal hidden actionable insights

Streamline Site Operations:

Optimize yield across multiple testing sites with comprehensive site and tester-based analysis tools.

Customized Integrations

Modular:

Tailored solutions that evolve with sector needs and are easily scalable on either On-Prem, Cloud or Hybrid infrastructure.

Craft Custom Solutions:

Provide end-to-end personalized yield management solutions catering specifically to the needs of the electronics industry.

Why Choose yieldWerx

Self Service Capability for Report Creation

Experience flexibility and control in crafting reports to suit your unique semiconductor needs.

100+ Management/SCM/Planning Widgets

Access widgets to update your management, supply chain, and planning activities, improving productivity.

Engineering & Quality Control Widgets

Use specialized widgets for engineering and design, ensuring top-notch product development and quality control.

Scalable Data Solutions

Explore cloud-hosted solutions in partnership with renowned providers like Amazon Web Services and Microsoft Azure.

PAT, GDBN Outlier Detection

yieldWerx spearheads advanced PAT and GDBN techniques in outlier detection, elevating semiconductor testing to precision quality control

Part Average Test (PAT)

yieldWerx revolutionizes chip manufacturing with zero-defect PAT solutions, enhancing quality and reliability in high-stakes industries.