Real Time and Predictive Analytics for Fabless Companies

Optimizing every stage of the manufacturing process for Fabless companies by enabling data-driven decision-making.

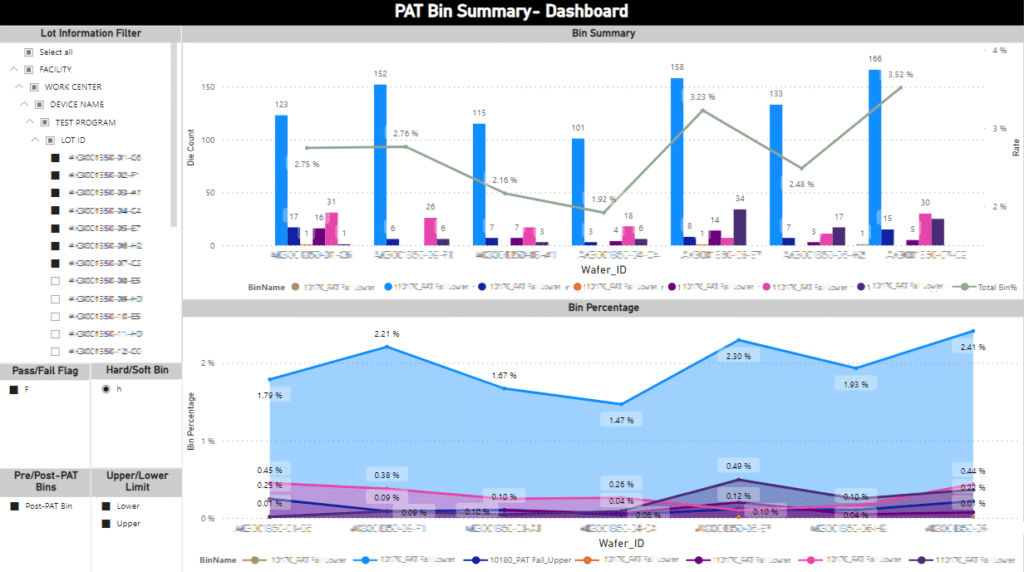

Advanced Visualizations and Analytics

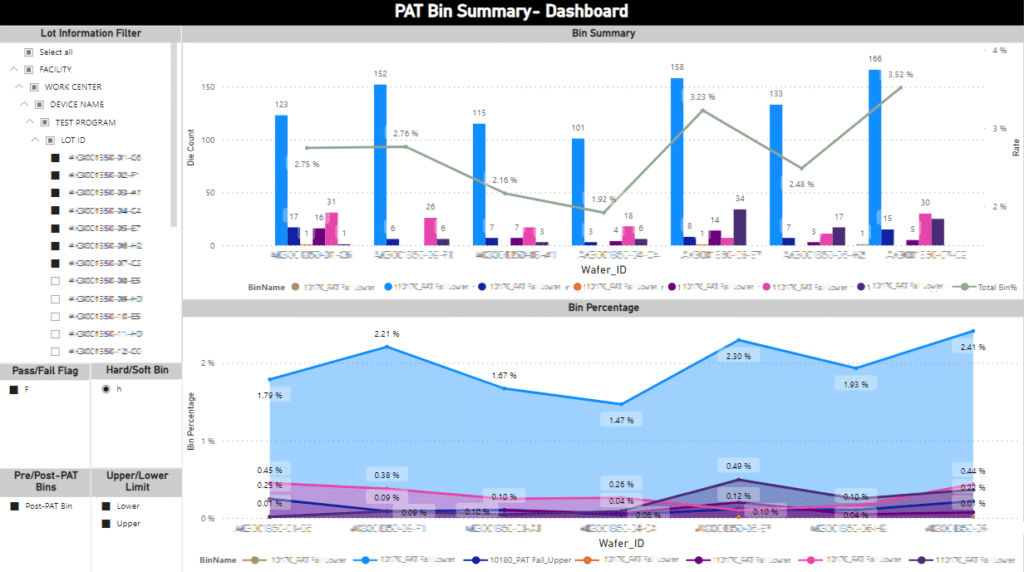

Streamlined Analytics and Reporting:

Monitor yield data and production metrics and create detailed reports to guide strategic decisions.

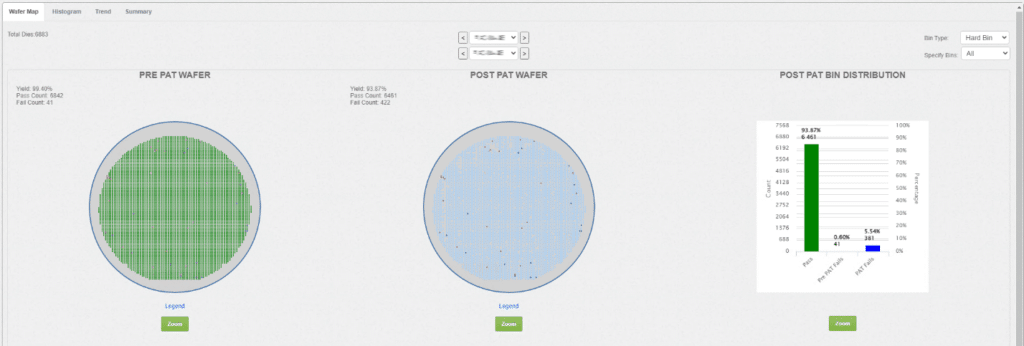

Advanced PAT and SPC:

Take advantage of our PAT module with static, dynamic, multivariant and non-Gaussian analysis options. Enhance production through real time parametric SPC control charts and alert system.

Automated Data Management:

Expediate data processing through automative workflows from over 100 different data sources. Streamline operations by merging PAT and SPC modules with MES systems directly.

Early Fault Detection:

Employ advanced statistical methods to predict and mitigate potential issues before they impact production and pinpoint areas for optimization and improvement.

Boosting Production Efficiency: Enhancing Yield and Speed

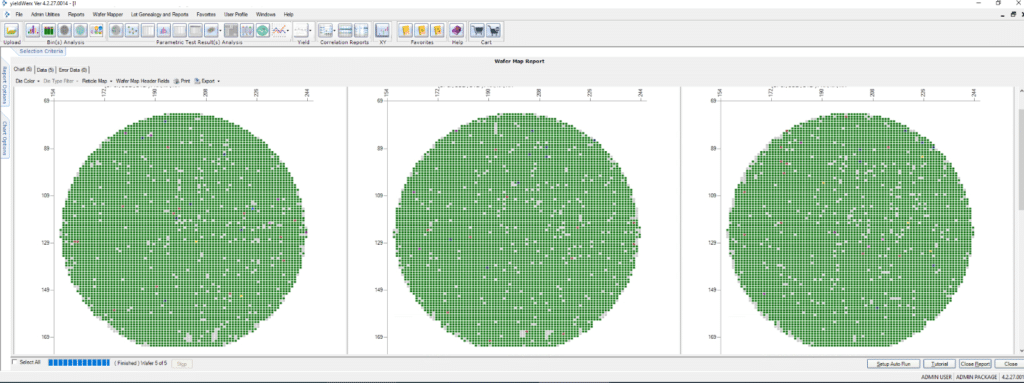

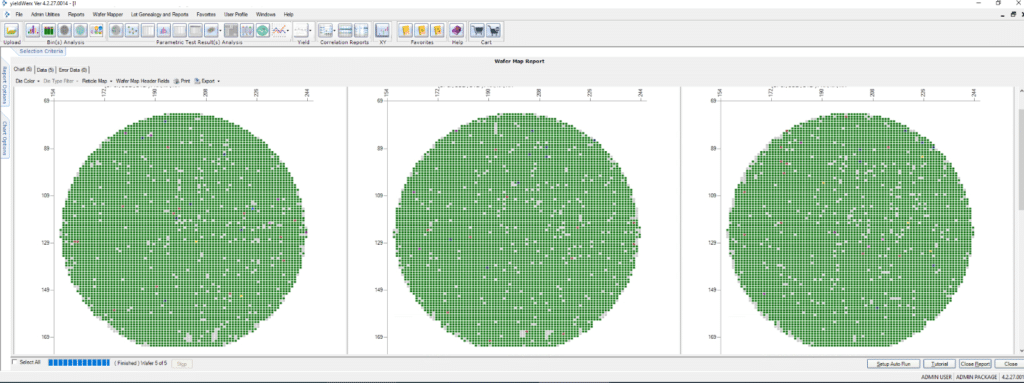

Improved Yield Optimization:

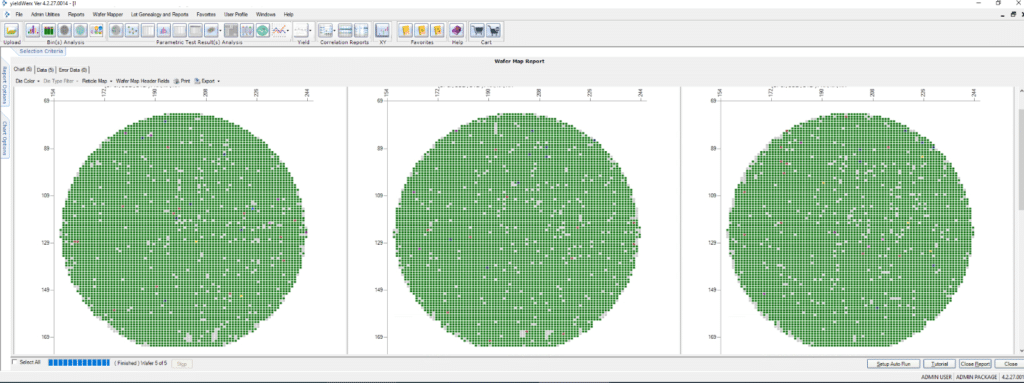

Identifying yield limiters and optimizing processes to enhance overall yield and product quality.

Faster Root Cause Analysis:

Quickly pinpointing the root causes of yield issues and defects to minimize production downtimes and improve product reliability.

Improved Testing Efficiency:

Optimizing testing processes, eliminating redundancy, and managing variations between test sites leading to reduced test times and costs

Reach Production Faster:

Quickly transition from design and testing to full-scale production with efficient yield management and real-time monitoring. Identifying yield limiters and optimizing processes to enhance overall yield and product quality.

Scalable Solution

Modular:

Tailored solutions that evolve with sector needs and are easily scalable on either On-Prem, Cloud or Hybrid infrastructure.

Custom Development:

Get extensive modeling and real-time analytics specific to the company’s requirements through our experienced team.

Real Time and Predictive Analytics for Fabless Companies

Optimizing every stage of the manufacturing process for Fabless companies by enabling data-driven decision-making.

Advanced Visualizations and Analytics

Streamlined Analytics and Reporting:

Monitor yield data and production metrics and create detailed reports to guide strategic decisions.

Advanced PAT and SPC:

Take advantage of our PAT module with static, dynamic, multivariant and non-Gaussian analysis options. Enhance production through real time parametric SPC control charts and alert system.

Automated Data Management:

Expediate data processing through automative workflows from over 100 different data sources. Streamline operations by merging PAT and SPC modules with MES systems directly.

Early Fault Detection:

Employ advanced statistical methods to predict and mitigate potential issues before they impact production and pinpoint areas for optimization and improvement.

Boosting Production Efficiency: Enhancing Yield and Speed

Improved Yield Optimization:

Identifying yield limiters and optimizing processes to enhance overall yield and product quality.

Faster Root Cause Analysis:

Quickly pinpointing the root causes of yield issues and defects to minimize production downtimes and improve product reliability.

Improved Testing Efficiency:

Optimizing testing processes, eliminating redundancy, and managing variations between test sites leading to reduced test times and costs

Reach Production Faster:

Quickly transition from design and testing to full-scale production with efficient yield management and real-time monitoring. Identifying yield limiters and optimizing processes to enhance overall yield and product quality.

Scalable Solution

Modular:

Tailored solutions that evolve with sector needs and are easily scalable on either On-Prem, Cloud or Hybrid infrastructure.

Custom Development:

Get extensive modeling and real-time analytics specific to the company’s requirements through our experienced team.

Why Choose yieldWerx

Self Service Capability for Report Creation

Experience flexibility and control in crafting reports to suit your unique semiconductor needs.

100+ Management/SCM/Planning Widgets

Access widgets to update your management, supply chain, and planning activities, improving productivity.

Engineering & Quality Control Widgets

Use specialized widgets for engineering and design, ensuring top-notch product development and quality control.

Scalable Data Solutions

Explore cloud-hosted solutions in partnership with renowned providers like Amazon Web Services and Microsoft Azure.

PAT, GDBN Outlier Detection

yieldWerx spearheads advanced PAT and GDBN techniques in outlier detection, elevating semiconductor testing to precision quality control

Part Average Test (PAT)

yieldWerx revolutionizes chip manufacturing with zero-defect PAT solutions, enhancing quality and reliability in high-stakes industries.