Top Ways Your Yield Management System Should Work for You

Whether you are a design house that outsources the manufacturing and testing process or an IDM that ships a finished product. A high stable yield rate is arguably the single most important key to a profitable business line. Pinpointing factors that limit yield especially when struggling with large volumes of data, requires a custom and systematic approach to yield management. Resolving yield issues means getting your product to market faster, saving on product re-spins. It also helps the engineers focus on solving problems faster and more efficiently without adding more bodies and tools.

Gone are the days when engineers have to massage data out of excel files and scripts looking for the root causes of yield loss. Today, competition is such that stringent set of guidelines such as Part Average Testing (PAT) are being pushed for across all industries. Consistent product reliability and profitable margins cannot be achieved without an easy-to-use and dynamic yield management solution. With that, end-to-end yield management solution is a must have for not only product and design engineers. It is also equally important for operations, management and ultimately the end users as reliability is key to a sustainable business.

Here are the top 6 must-have features your yield management solution should offer:

- Ease of Use – should be up and running with minimal training for engineers and management combined.

- A single point of access to get all your data collected within minutes – ability to read in multiple data formats from multiple sources.

- Ability to do Full Genealogy Analytics

- Ability to create automated and meaningful reports within minutes so your engineers will spend time analyzing the results rather than putting together the data.

- A modular approach to analysis and licensing – so you don’t have to pay for features you don’t use

- Around the clock dedicated and experienced customer service

How yieldWerx Solution Works

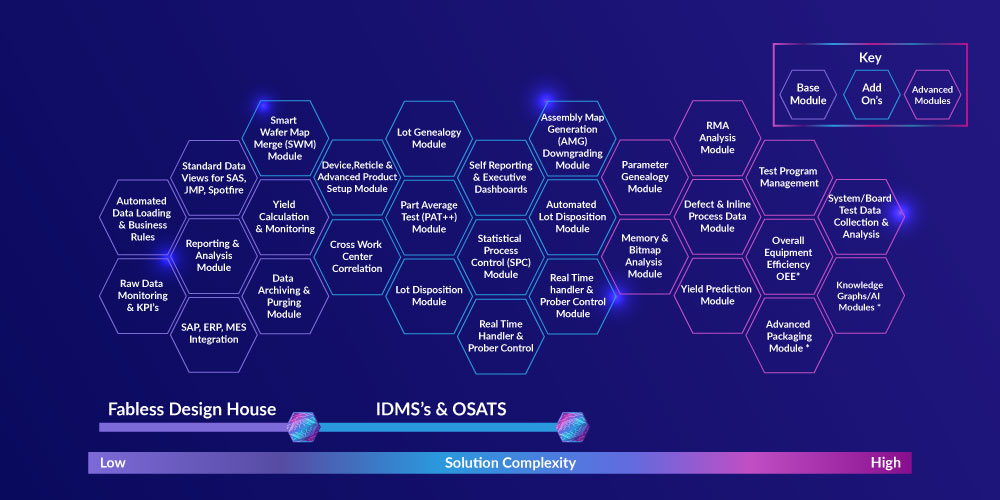

yieldWerx end-to-end yield management solution consists of modules to address all levels of yield management complexity. Moreover, yieldWerx targets customers range from fabless design houses to IDMs and OSATs. Our solution partners include test equipment manufacturers such as Teradyne, LTX-Credence, Chroma, HP, Advantest. We also cater foundries such as TSMC, Global Foundries, UMC, SMIC and ASMC.

Building on our yieldWerx Enterprise Modules, which can be applied to every customer are Add Ons and advanced modules that you can pick and choose to fit your process environment and needs.

Fig1: yieldWerx Modular Yield Management Solution

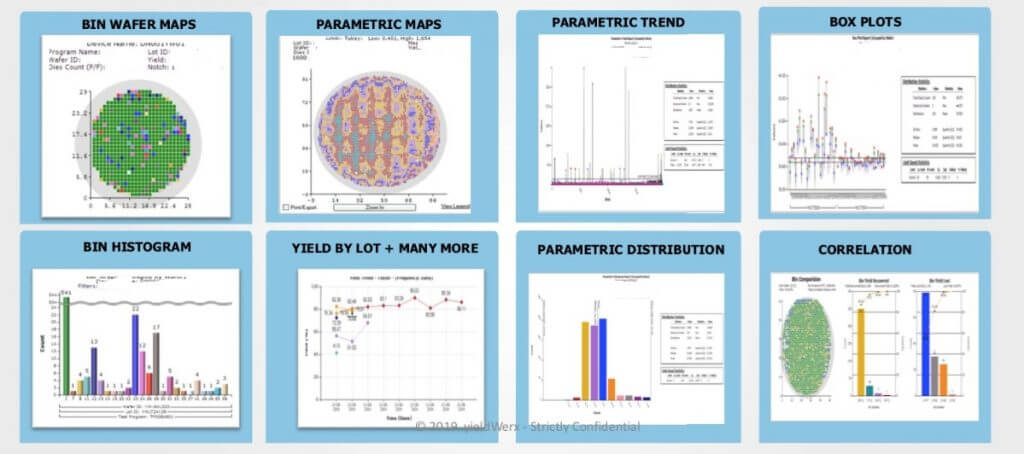

We capture data from hundreds of formats including STDF, ATDF, CSV and any other proprietary format. We also offer a comprehensive suite of over 100 reports ranging from Bin, Yield, Parametric, Characterization, Correlation and many more.

Fig2: yieldWerx Reporting & Analytics – The Basics

Here is how yieldWerx adds value to your yield management and stands out from the rest. Our advanced modules and analysis include:

- Lot Genealogy and Data Analysis Across Multiple Work Centers Enabled via Lot Genealogy. You can see our Case Study here to read about how yieldWerx’s powerful reporting and analysis capabilities helped one customer achieve their goal of yielding 98% at the final test stage.

- Statistical Process Control (SPC) with Real Time Alerts and Equipment Stop

- Ability to put equipment or lots/wafers on ‘HOLD’ for engineering disposition. So, see our Case Study to read about how yieldWerx SPC module helped fabless semiconductor company achieve early detection and warning of bad lots prior to shipment.

- Engineering Characterization

- Memory & Bitmap Analysis

- PAT with Static & Dynamic PAT, Good Die Bad Die Neighborhood Analysis (GDBN), Statistical Bin Limits (SBL)/ Statistical Yield Limits (SYL) functionality for multi-site testing

- Eliminate Outlier Die at Final Test or post wafer sort.

- Downgrade Good Die where parametric values are not within the normal distribution.

- Real Time Final Test Dynamic PAT

- Provide Real Time Dynamic Limits to the tester/test program.

- Factor in operational issues (Shift change, Test Program crashes, changing from single site to multiple sites and vice versa)

- Smart Probe Ability

- Have Skip Die, Next Die, Previous Die Controls

- Ability to probe the back and front of wafer – in either order or then only probe the die that passed from the first pass.

- Cloud-based subscription license for quick startup and easy, usage-based scalability with no hardware costs

A comprehensive and easy to use yield management system like yieldWerx will enhance equipment throughput. It will also optimize testing process and result in competitive advantage in the market and financial savings.

Sign up for a 15 days free trial or schedule a live demo today for a chance to test your data with yieldWerx yield management system.

Keep up-to-date with yieldWerx by following us on LinkedIn and Twitter.

Tags In

Recent Posts

- AI-Powered PAT: A New Era of Smarter Manufacturing

- KLARF File Format: Enhancing Semiconductor Yield Analysis with yieldWerx

- The 2022 CHIPS Act May Be Repealed: What Does This Mean for You?

- End-to-end Semiconductor Data Analytics and Traceability Solutions For Multi-Chip Packages

- Semiconductor Traceability Using Lot Genealogy For Multi-Chip Modules