9 Benefits of Using a Yield Management System

Fabless companies often struggle with the big amount of data produced about their products manufacturing and testing results. In order to properly analyze this data, the companies are faced with two options:

- Hire dedicated engineers to organize and process this amount of data.

- Use a Yield Management System (YMS).

In fact, the usage of a good YMS solution comes really in handy for fabless startups and is much more advantageous than hiring dedicated engineers. Here are nine main benefits that yieldWerx YMS solution has to offer.

1) Real-time tracking of production issues

With the aid of real-time big data analytics, a variety of implemented algorithms are used to detect things out of order in the production process that are likely to cause problems, once you tell the YMS a set of rules upon which it should send you an alert to prevent escapes. On the other hand, a production engineer is likely to spend much time analyzing the data himself after the production problems have occurred.

2) Performing Outlier Detection Methods

One of the main usages of a YMS solution is to perform a variety of outlier detection algorithms such as Part Average Testing (PAT), Good Die in Bad Neighborhood (GDBN), Statistical Bin Limits (SBL)… etc. These tests are used to identify ICs that, though passed semiconductor manufacturing tests, are likely to cause reliability issues such as infant mortality. These ICs are considered “outliers” and get disposed of if they fail outlier detection algorithms.

3) Root causes analysis

A good YMS system is capable of giving engineers insights towards the root causes of chip failures so as to be able to eliminate them in the future and recover the lost yield. For example, yieldWerx offers Lot Genealogy module that stores all the history and related information for all chips. This module is bundled with Cross Work Center Correlation module, and the usage of the two modules enables to identify potential correlations between chip failures and potentially causing parameters.

4) Big Data & Format Flexibility

A dedicated engineer is likely to spend a lot of time organizing huge and continuous amounts of data in sheets and databases. Meanwhile, yieldWerx YMS system is able to automatically accept data input in any format (CSV, TST, STDF, WAT… etc.) in a daily basis, which saves engineering time and effort.

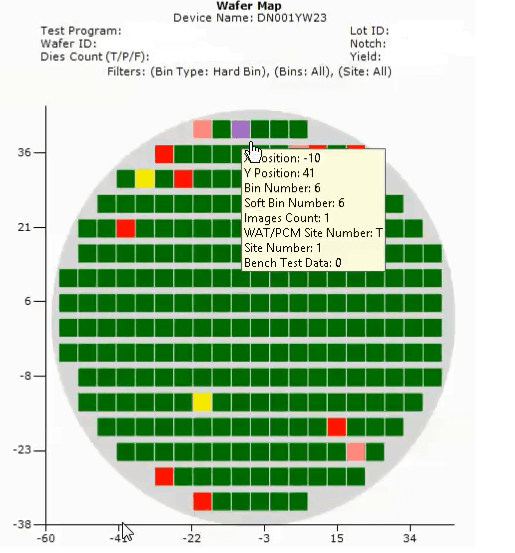

5) Wafer Maps Generation

One of the main goals of YMS solutions is to help with data visualization. Thus, yieldWerx YMS solution generates wafer maps for semiconductor test results showing dies bin numbers, WAT/PCM site number, bench test data or final test data. It also offers an advanced module for memory and bitmap analysis.

Fig. 1: A wafer map generated by yieldWerx YMS solution

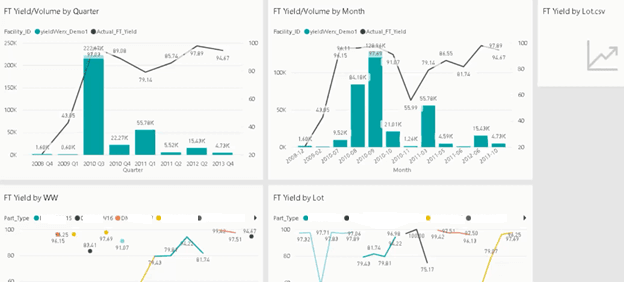

6) Automated generation of reports

It takes a dedicated engineer much time and effort to analyze the tests data and produce performance reports. With increasing complexity and size of production, this situation is just getting worse. Meanwhile, yieldWerx YMS solution is capable of organizing the output data automatically and generate the required reports including numbers, charts and graphs. With the help of cloud servers, yield reports could be sent directly to your inbox in a daily manner, which not only saves effort but also provide information in a timely, organized and consistent manner. The YMS solution also provides very useful information about the production performance parameters, the yield, the cost, the profit… etc., with time.

Fig. 2: Yield charts generated by yieldWerx YMS solution in online dasboards.

7) Calculating Overall Equipment Efficiency (OEE) Metric

The goal of YMS solutions in not only related to the production of chips, but it is also concerned with the overall productivity. OEE calculation gives insights towards the shipped products quality, the performance of existing equipment – how quick production is taking – and the availability percentage of the equipment.

8) It makes the fabless companies in control

Using the many sophisticatedly-designed user-friendly available tools and capabilities of yieldWerx YMS, the fabless companies’ engineers can use it themselves to do the analysis and be in very close supervision of the production process and its results analyses. This, in turn, enhances understanding of the production process and its potential issues, which accelerates the necessary measures to be taken to resolve them.

9) Financial Efficiency

The usage of a YMS solution is not only performance efficient; it is also financially efficient! In fact, a YMS solution costs one third the salary of a dedicated production engineer. This way, the YMS solution enables the company engineers to have much more time to add real value to the design and the production process itself.

Take a 15 days freetrial or schedule a demo to uncover the potential of your data when processed by yieldWerx.

Recent Posts

- The Complete Guide to Wafer Defect Detection Using Knowledge Graphs in 2025

- AI-Powered PAT: A New Era of Smarter Manufacturing

- KLARF File Format: Enhancing Semiconductor Yield Analysis with yieldWerx

- The 2022 CHIPS Act May Be Repealed: What Does This Mean for You?

- End-to-end Semiconductor Data Analytics and Traceability Solutions For Multi-Chip Packages