Understanding the Significance of STDF Data in Semiconductor Testing

Accurate and efficient test data management is crucial in the semiconductor industry for maintaining high yields and ensuring product quality. Among the various formats used to store test data, the Standard Test Data Format (STDF) has emerged as the most widely adopted format. But what makes STDF so indispensable?

What is STDF?

STDF, short for Standard Test Data Format, is a binary format specifically designed to store test data from Automated Test Equipment (ATE). This format is versatile, supporting a wide range of test types, including parametric, functional, and high-frequency testing. Unlike the familiar spreadsheets and tables, STDF organizes data in a more compact and structured manner, which might seem unfamiliar at first glance but offers significant advantages in data handling and storage.

Why Engineers Prefer STDF

One of the primary reasons engineers favor STDF is its consistency. Adopting a standard format like STDF stores all test data uniformly, making it easier to share and analyze across different platforms and teams.

While STDF is a binary format, there is also an ASCII version known as ATDF. Although ATDF is readable in any text viewer, STDF’s binary format is faster for ATE computers to write, which is crucial as test time directly impacts product costs. This speed advantage often makes STDF the preferred choice in testing environments.

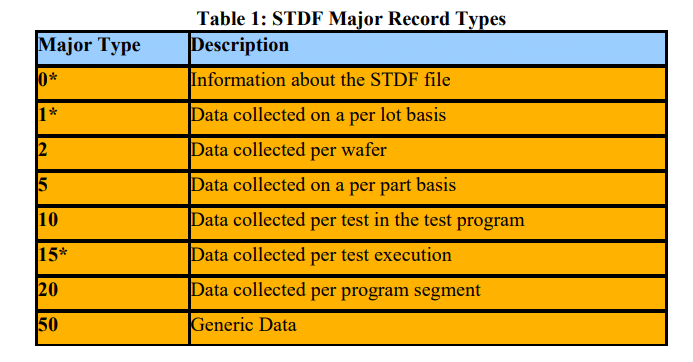

Key STDF Record Types

STDF is organized into defined record types, each specified in the format’s documentation regarding the type of data it contains, its size limit, and the data type of each field. Some of the essential record types include:

- File Attributes Record (FAR)

- Version Update Record (VUR)

- Master Information Record (MIR)

- Master Results Record (MRR)

- Part Count Record (PCR)

- Hardware Bin Record (HBR)

- Software Bin Record (SBR)

- Pin Map Record (PMR)

- Wafer Information Record (WIR)

- Wafer Results Record (WRR)

- Wafer Configuration Record (WCR)

- Pattern Sequence Record (PSR)

- Part Information Record (PIR)

- Part Results Record (PRR)

- Parametric Test Record (PTR)

- Multiple-Result Parametric Record (MPR)

- Functional Test Record (FTR)

These records ensure that test data is stored consistently and efficiently, facilitating smoother data analysis and management processes.

The Challenges of STDF

While STDF remains popular due to its established history and widespread adoption, it has limitations. As chip designs have become more complex, STDF files have increased in size, leading to challenges in storage and processing. Additionally, the rigid structure of STDF can make it less adaptable to new testing methodologies and data types. The format’s limited ability to capture comprehensive metadata further constrains the scope of analysis that can be performed.

For example, the test description field in STDF is restricted to just 255 characters, requiring engineers to be creative in naming conventions to fully capture test conditions and relevant information.

Converting STDF Data for Usable Analysis

Despite its advantages for ATE, STDF is not inherently user-friendly for data analysis. Therefore, it often needs to be converted into a more accessible format. While open-source libraries in Python, R, or C++ exist for this purpose, they can be challenging to handle without proper expertise.

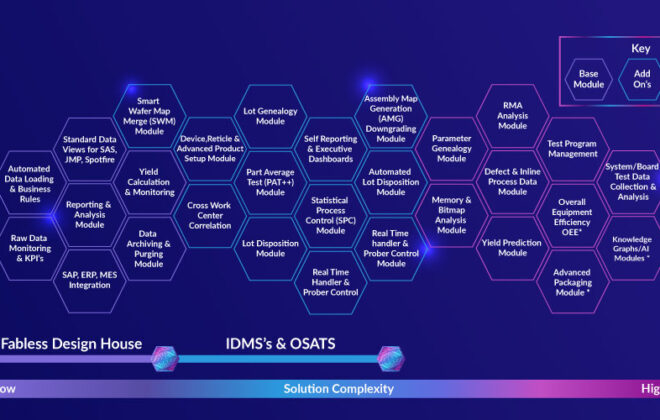

Simplifying STDF Data Analysis with yieldWerx

At yieldWerx, we understand the complexities involved in STDF data analysis, so our solutions are designed to make this process as simple and efficient as possible. Our platform enables real-time upload, viewing, and modification of STDF files, providing key insights and enabling quick adjustments to improve yields.

Key Features of yieldWerx for STDF Data Handling:

- Data Manipulation: Effortlessly customize and modify STDF data, allowing you to tailor insights to your specific needs.

- Data Loading Engine: Experience fast data handling and multi-location management with our advanced loading engine.

- Conversion Capabilities: Convert STDF files into Excel, database, text, or XML formats, facilitating swift decision-making.

- Compatibility and Data Handling: Seamlessly integrate raw data from all major ATEs, fabs, and test houses, ensuring compatibility with STDF, ATDF, and other formats.

- Ease of Data Import: Quickly import data into yieldWerx enterprise, enabling informed decision-making through smooth data importation.

- One-click STDF Data Precision: Gain instant insights with real-time analysis of STDF data precision, supporting both manual uploads and scheduled processes with just one click.

By leveraging yieldWerx, companies can overcome the challenges associated with STDF data, streamlining their test engineering processes and enhancing overall efficiency Learn more.

In conclusion, while STDF remains a cornerstone format in semiconductor testing, it requires the right tools and expertise to unlock its full potential. yieldWerx stands ready to help you harness the power of your STDF data, ensuring you stay ahead in the competitive semiconductor landscape.

List of References:

Recent Posts

- The Complete Guide to Wafer Defect Detection Using Knowledge Graphs in 2025

- AI-Powered PAT: A New Era of Smarter Manufacturing

- KLARF File Format: Enhancing Semiconductor Yield Analysis with yieldWerx

- The 2022 CHIPS Act May Be Repealed: What Does This Mean for You?

- End-to-end Semiconductor Data Analytics and Traceability Solutions For Multi-Chip Packages