How to Implement STDF Data Analysis for Improved Results in Semiconductor Manufacturing

The Standard Test Data Format (STDF), a file format developed for semiconductor testing, is a key player in semiconductor manufacturing. It plays a vital role in recording and storing test data, which is essential for analyzing the performance and quality of semiconductor products.

Managing and analyzing vast volumes of STDF files to maintain data accuracy can be challenging. This calls for specialized STDF data analysis tools designed to handle and interpret this complex data effectively.

Addressing these challenges is vital to using the full potential of STDF to improve semiconductor manufacturing outcomes.

Decoding Standard Test Data Format (STDF)

The Standard Test Data Format (STDF) is a specialized file format for storing test data. This format is integral to documenting the intricate details of each test conducted on semiconductor devices. STDF plays an important role in guiding semiconductor product analysis and quality assessment by providing a structured way to record large amounts of test results.

STDF’s Role in Data Analysis

STDF’s significance extends beyond data storage; it is vital to data analysis in semiconductor testing. This process, known as STDF data analysis, is central to identifying product defects and guaranteeing quality. It involves a detailed examination of test data facilitated by specific STDF data analysis tools. These tools are adept at optimizing the unique structure of STDF files, making them indispensable for accurate and efficient data interpretation.

Historical Perspective of STDF

The historical progression of STDF reflects the advancement of semiconductor technology. Originating in the late 20th century, it solved the problems posed by the burgeoning data from increasing semiconductor tests.

As semiconductor devices and testing methods evolved, so did STDF. It has continuously adapted, incorporating advanced features for more effective data management and analysis. This evolution signifies the industry’s commitment to adapting tools and methods to maintain quality and efficiency in semiconductor manufacturing.

Common Challenges in STDF Data Analysis

Dealing with STDF files in semiconductor manufacturing is often a complex task. Professionals frequently encounter several issues that can impede the efficiency of data analysis.

One primary challenge is the size and complexity of STDF files, which can be massive due to the extensive data generated in semiconductor testing. This complexity not only makes it difficult to handle these files but also poses challenges in terms of data integrity and accessibility.

Another issue is the variability in the format itself. While STDF files are standardized, they can vary slightly depending on the testing procedures and equipment used, leading to inconsistencies that require careful examination during analysis.

Data Loss and Metadata Management Concerns

Data loss is a significant concern when working with STDF files. The loss of critical test data can lead to gaps in analysis, impacting the quality control process. Guaranteeing the integrity and completeness of data is a constant challenge in STDF data analysis.

Alongside this, managing metadata is equally challenging. Metadata in STDF files provides context to the test results, such as information about test conditions, equipment used, and test parameters.

Issues with Data Precision

Data precision is another area of concern in STDF data analysis. The accuracy of test data is paramount, as even minor errors can lead to incorrect conclusions about the quality and performance of semiconductor products.

It involves careful data handling, often requiring advanced tools and expertise. This is particularly challenging given the nature of STDF data, which includes a range of data types, from binary and text to floating-point numbers, each requiring careful consideration during analysis.

Optimal Strategies for STDF Data Analysis

In STDF data analysis, adopting optimal strategies is key to get meaningful insights from semiconductor test data. These strategies focus on efficient metadata management, discerning use of data records, and precision in handling complex data types.

Strategies for Metadata Management

Effective management of metadata in STDF data analysis is essential. A systematic approach to organizing and categorizing metadata helps its accurate retrieval and use. Implementing a methodical system for indexing metadata guarantees quick and precise access to relevant information.

Clear documentation of metadata fields, outlining their definitions and how they relate to test data, is also vital. This practice aids in understanding the data’s context and maintains uniformity in analysis across various datasets.

Detailed Review of Metadata Fields

A detailed review of metadata fields is essential in STDF data analysis. Regular audits of metadata ensure its accuracy and pertinence. Identifying and correcting discrepancies in metadata is necessary to avoid skewed analysis.

Additionally, comparing metadata with the actual test data frequently makes sure that the metadata accurately reflects test conditions and outcomes.

Advanced Tools for Managing and Analyzing STDF Data

Managing and analyzing STDF data requires sophisticated tools and techniques in semiconductor manufacturing. These tools address the complexities of managing and analyzing vast volumes of STDF data.

Features of Advanced STDF Data Management Tools

Modern STDF data management tools come equipped with a range of features customized to meet the specific needs of semiconductor manufacturing. Key capabilities include automated data loading, which allows handling large volumes of data from diverse sources.

These tools also provide functionalities for thorough data analysis, including the ability to read, view, modify, and convert STDF files into various formats. This flexibility is important in addressing the diverse analytical requirements of semiconductor manufacturing.

Improving Productivity with Efficient Data Analysis

Advanced STDF data analysis tools are about managing data and boosting productivity through efficient data analysis. These tools can significantly speed up data queries and analysis by utilizing unique test number indexing and efficient storage utilization. This efficiency is key in a high-stakes industry where timely and accurate data analysis can directly impact production quality and operational efficiency.

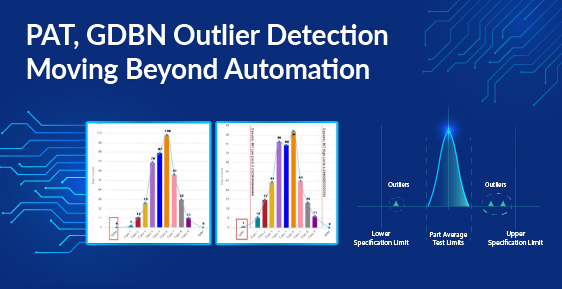

The Role of Advanced Tools in Yield Management

In yield management, using advanced STDF data analysis tools is indispensable. These tools aid in identifying yield limiters and facilitate manufacturing process enhancements. By providing comprehensive insights into test data, manufacturers can make informed decisions, leading to improved yields and reduced manufacturing costs.

They facilitate efficient data processing, offer flexibility in data handling, and support various data formats essential for semiconductor manufacturing. yieldWerx™ is the leading platform known for its capabilities in handling diverse data formats like STDF, ATDF, CSV, and more.

Capabilities of yieldWerx in STDF Data Analysis and Management

yieldWerx comes with a powerful data-loading engine and the ability to process complex data from multiple sources simultaneously. This feature is handy for semiconductor companies with large and varied datasets.

The tool’s functionalities extend to modifying, reading, viewing, and converting STDF files into several formats, such as Excel, database, text, and XML. These capabilities make yieldWerx an integral part of the decision-making process in semiconductor manufacturing. It offers advanced data analysis features and real-time alert systems, aiding companies in maintaining product quality while fostering innovation.

The tool’s ability to perform statistical analysis on STDF files and generate insightful reports is valuable for engineers who monitor operations and identify key issues.

Advanced tools like yieldWerx are reshaping the approach to STDF data management in semiconductor manufacturing. They are important for processing large volumes of data, providing comprehensive data analysis capabilities, and supporting decision-making processes. Integrating such tools is essential for maintaining competitiveness and operational efficiency in the semiconductor industry.

Conclusion

The historical perspective of STDF mirrors the advancement in semiconductor technologies. Its inception and subsequent evolution reflect the industry’s response to the growing demand for more efficient data-handling methods. Implementing advanced platforms like yieldWerx in semiconductor manufacturing and testing is not just a matter of data management convenience; it is a strategic move toward operational efficiency and quality assurance.

Frequently Asked Questions (FAQs)

1. What is STDF, and why is it important in semiconductor manufacturing?

STDF (Standard Test Data Format) is a file format used extensively in semiconductor manufacturing to store test data. This format is important because it records detailed results of tests conducted on semiconductor devices.

2. What are the common challenges associated with STDF data analysis?

The primary challenges in analyzing STDF data include managing its large volume and complexity. Guaranteeing data accuracy and integrity is also a significant task, as errors can lead to incorrect conclusions about product quality.

3. How can yieldWerx improve the STDF data analysis process?

yieldWerx improves the STDF data analysis process by providing a comprehensive solution that automates several critical tasks. This includes automated data loading, real-time anomaly detection, and external data source integration.

4. What are the key features of yieldWerx that support STDF data analysis?

yieldWerx offers several features that support efficient STDF data analysis. These include automated assembly map generation, smart wafer merge, and various advanced modules like defect data management and inspect image management.

5. How does yieldWerx guarantee accurate and efficient data analysis?

yieldWerx ensures accuracy and efficiency in data analysis through its multi-tier architecture, which separates user interface, application processing, and data management functions.

Recent Posts

- 5 Strategic Shifts to Capture Shares in the $1 Trillion Global Chip Market

- Chiplets: The Building Blocks of Sustainability

- The Complete Guide to Wafer Defect Detection Using Knowledge Graphs in 2025

- AI-Powered PAT: A New Era of Smarter Manufacturing

- KLARF File Format: Enhancing Semiconductor Yield Analysis with yieldWerx