Why It is a Good Idea to Outsource Your Yield Management System

Typically, a yield management solution is born out of necessity. A well-established technology node needs it to stay competitive and profitable whereas a new product needs it to quickly diagnose…

Top Ways Your Yield Management System Should Work for You

Whether you are a design house that outsources the manufacturing and testing process or an IDM that ships a finished product. A high stable yield rate is arguably the single…

Advanced Characterization Management for Fast Qualification

In the Semiconductor Age, billions of products worldwide depend on the reliability of ICs. The competitiveness in the semiconductor industry is extremely hard. Therefore, as an example, manufacturers are constrained…

Adapting to the Automotive Benchmarks

In 2019, ICs automotive products represent more than 10 % of the worldwide semiconductor profits. The automotive semiconductor sector is expected to experience a compound annual growth rate of 18…

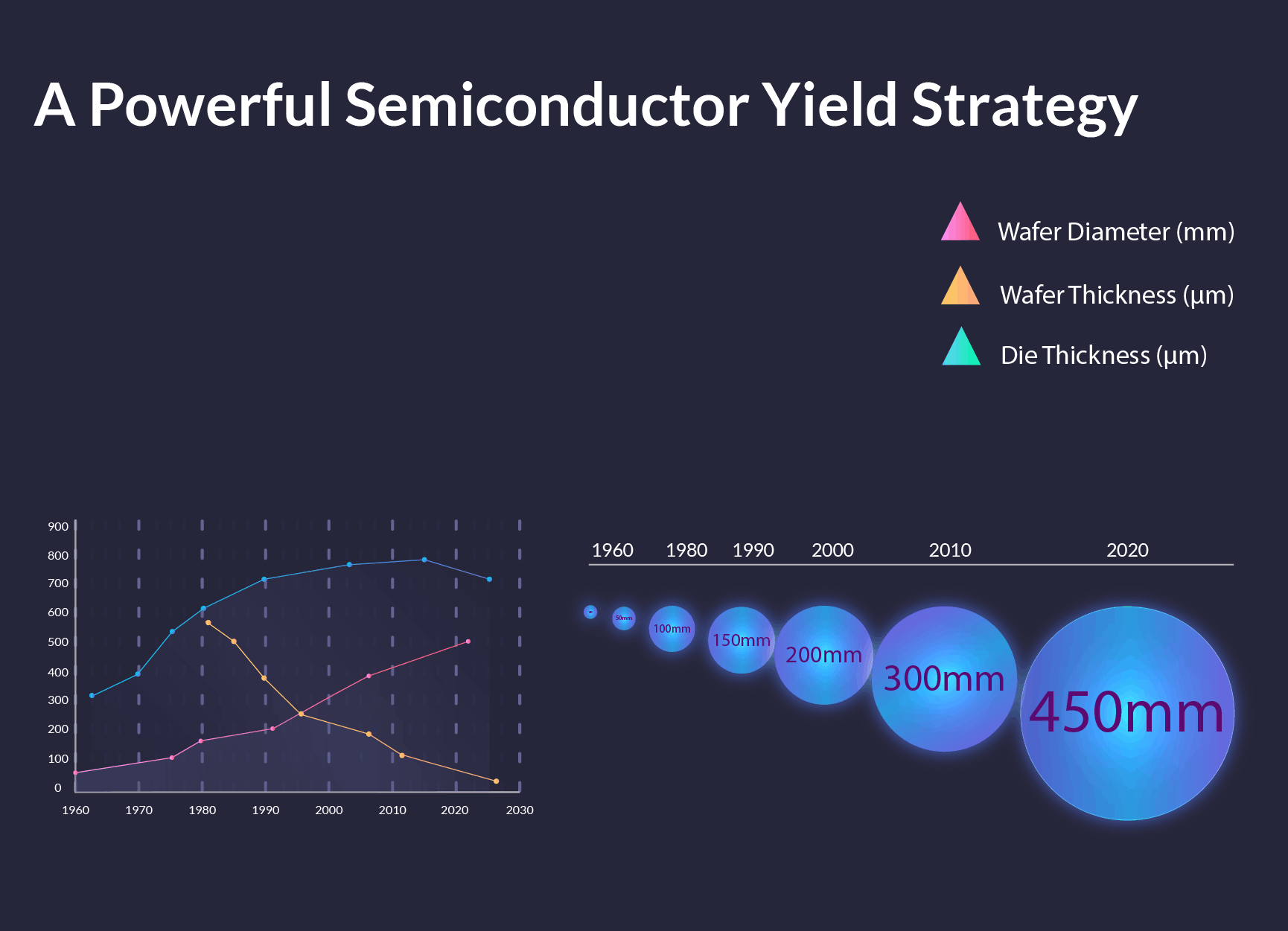

A Powerful Semiconductor Yield Strategy

Every decent semiconductor company has a system to track in real time the yield of the Fab’s products. Increasing the yield not only enhances directly the profit by using as…

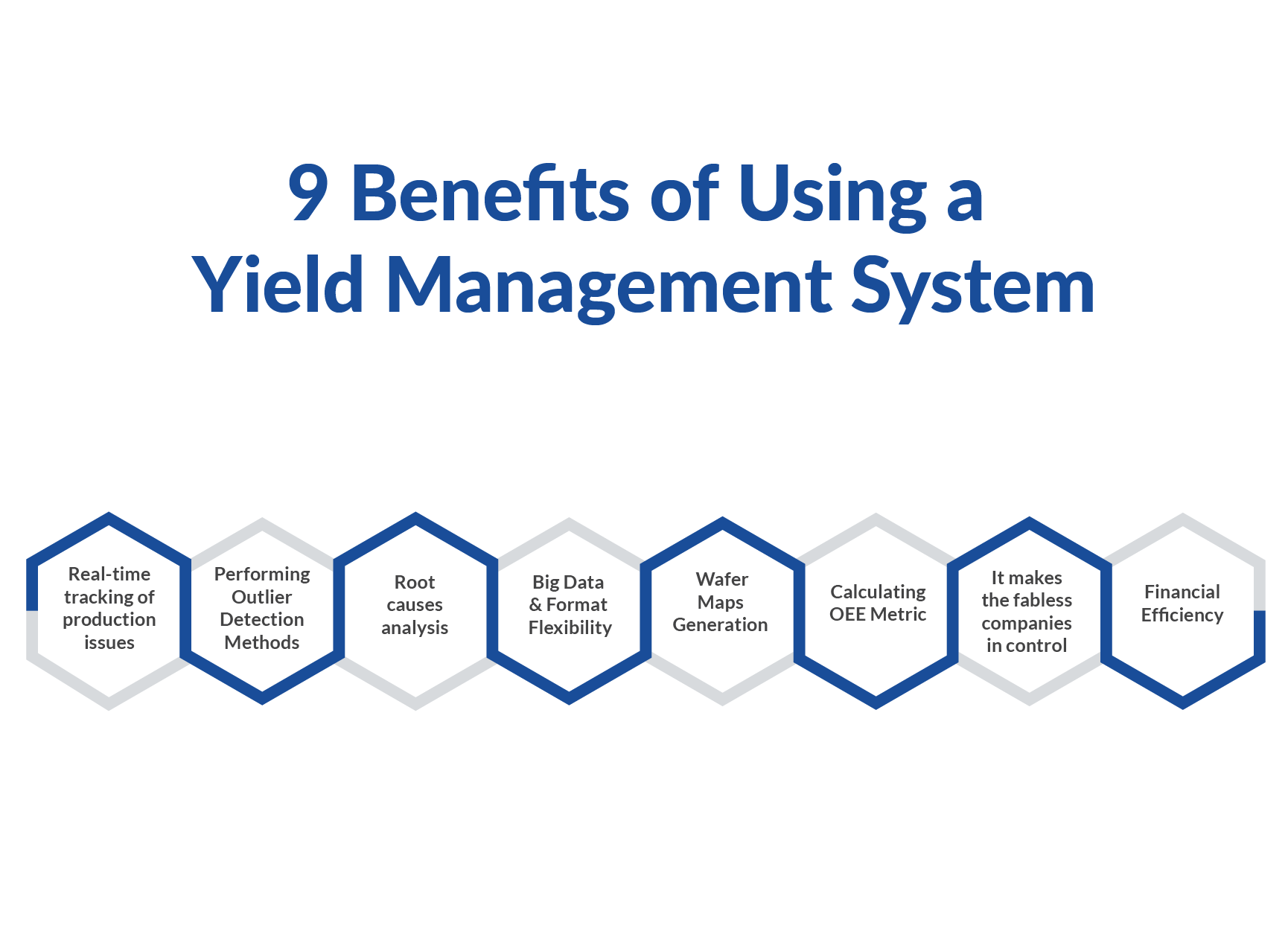

9 Benefits of Using a Yield Management System

Fabless companies often struggle with the big amount of data produced about their products manufacturing and testing results. In order to properly analyze this data, the companies are faced with…

Big Data Takes Over the Semiconductor Production

Processing the data from sensors or test equipments in a production line is a powerful strategy to analyse in real time the health of your products. It gives a clear advantage to your company in

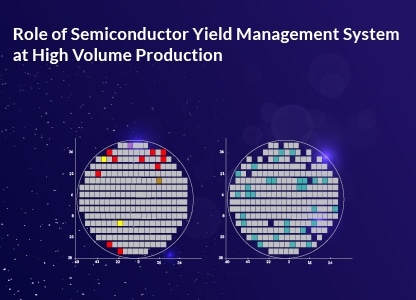

Role of Semiconductor Yield Management System at High Volume Production

Semiconductor wafer fabrication plant is one of the most capital intensive unit with a production cycle of more than 6 weeks. Typically, a modern state of the art process fabrication…

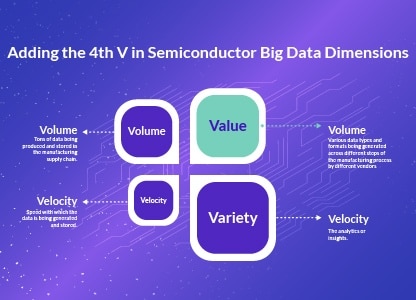

Adding the 4th V in Semiconductor Big Data Dimensions

The semiconductor manufacturing industry has witnessed drastic changes over the time and these changes have made semiconductor manufacturing one of the most complex and highly advanced industry where each product…

Ensuring Quality and Reliability in Global Supply Chains

With the ever increasing rise of competition in the industry, the semiconductor manufacturing is moving towards highly specialized, advanced and complex processing of wafers. The supply chain is getting more…

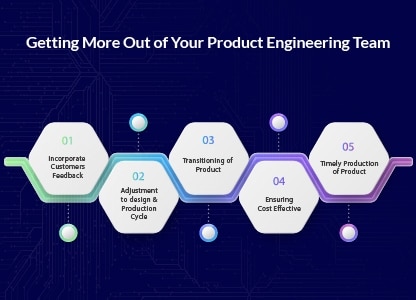

Getting More out of your Product Engineering Team

Semiconductor wafer manufacturing is a long and complex process comprising of several process steps. Normally it takes somewhere between five weeks to several months to manufacture a fully functional IC…

PAT, GDBN Outlier Detection Moving Beyond Automotive

Semiconductor testing is a walk on the tightrope because of the latent defects that emerge in chips later in their life when they are part of an end-product. That’s why…