Distinguishing between parametric and non-parametric test analysis is essential for the functionality of semiconductor components. Testing methods are central to semiconductor chip testing and are critical in confirming these vital elements’ operational integrity and performance standards.

This guide will help you understand the comparative analysis of these testing strategies. It will focus on their implications for semiconductor testing to illuminate how they contribute to semiconductor products’ overall yield and dependability.

Basics of Statistical Analysis in Semiconductors

In semiconductor manufacturing, statistical analysis is critical for guaranteeing quality and efficiency. This analytical approach is also fundamental in semiconductor testing, where it validates the integrity and performance of semiconductor chips.

Through statistical analysis, engineers and technicians can accurately assess manufacturing processes, identify variations, and take corrective measures, thus maintaining data integrity and optimizing manufacturing yield.

Statistical analysis involves various aspects of semiconductor production, from process control to outlier detection. By utilizing rigorous data analysis methodologies, semiconductor industries can make informed decisions, reduce waste, and improve the reliability of their products. This contributes to cost efficiency and ensures the final products meet high standards.

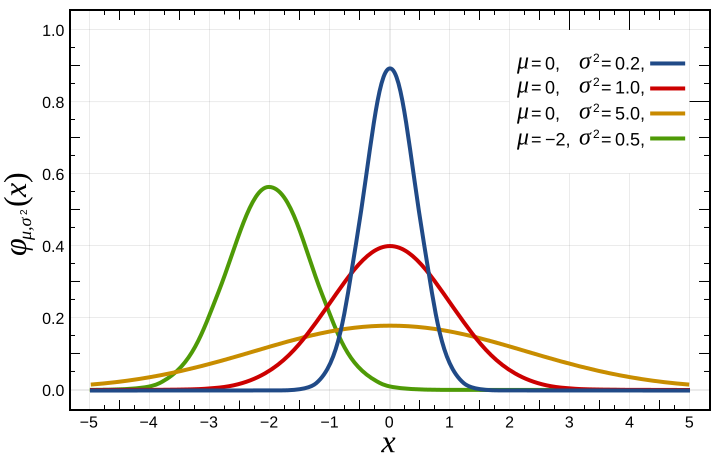

Within the spectrum of statistical analysis in semiconductor testing, two primary methodologies stand out: parametric testing and non-parametric testing. Parametric testing, or parametric statistics, involves statistical tests that assume a specific data distribution, typically a normal distribution.

Parametric Test Analysis

Parametric testing in semiconductor testing refers to a group of statistical tests that assume the underlying data follows a specific distribution, typically a normal distribution. These tests rely on parameters—such as mean and standard deviation—to make inferences about the data.

This approach is particularly useful when dealing with large datasets where the central limit theorem assures normal distribution. Parametric tests are integral in statistical analysis, offering precision in hypothesis testing and data analysis, which are essential for semiconductor characterization and process control.

Common Parametric Tests in Semiconductors

Several parametric tests are routinely employed in the semiconductor industry.

- The t-test, for instance, is used to compare means between two groups, while ANOVA (Analysis of Variance) is utilized to compare means across multiple groups.

- Another common parametric test is the regression analysis, which is used to model and analyze the relationship between variables, aiding in the design of experiments and statistical process control.

These tests are essential in evaluating semiconductor chip testing results, ensuring the consistency and reliability of the chips.

Advantages of Parametric Testing

The primary advantage of parametric testing lies in its efficiency and precision, especially when the assumptions about the data distribution are met.

These tests are more powerful than their non-parametric counterparts, capable of providing accurate estimates and more reliable results when conditions are satisfied. In semiconductor testing, parametric tests can effectively identify subtle differences and patterns in data, contributing to enhanced data integrity and manufacturing yield.

Limitations of Parametric Testing

However, the effectiveness of parametric testing is contingent on fulfilling its underlying assumptions. If these assumptions – such as data normality and homoscedasticity – are not met, the results of parametric tests can be misleading.

This limitation becomes significant in semiconductor chip testing when dealing with small sample sizes or non-normal data distributions. Additionally, the rigidity of assumptions in parametric tests can limit their applicability in certain semiconductor characterization scenarios, where data may not conform to standard distributions.

While parametric testing is a powerful tool in semiconductor testing, understanding its limitations is important for accurate interpretation of results and effective decision-making in semiconductor manufacturing and process control.

Non-Parametric Test Analysis

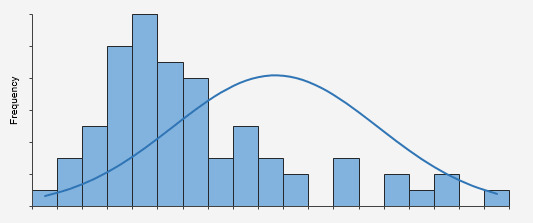

Non-parametric testing, a key component in semiconductor testing, is distinct from its parametric counterpart. Unlike parametric tests, non-parametric tests do not rely on assumptions about the underlying data’s distribution.

This feature makes them highly adaptable and suitable for various data types, especially when dealing with ordinal data or when the sample size is too small to estimate parameters reliably.

In semiconductor chip testing, non-parametric tests are valuable tools for statistical analysis and data analysis when the data does not meet the stringent assumptions required for parametric testing.

Standard Non-Parametric Tests in Semiconductors

In the semiconductor industry, several non-parametric tests are commonly used.

- The Mann-Whitney U test, for example, is employed to compare two independent samples, while the Kruskal-Wallis test is used to compare more than two independent samples.

- Other notable non-parametric tests include Spearman’s rank correlation test and the Wilcoxon signed-rank test, which are used in semiconductor characterization to analyze ordinal or non-normally distributed interval data.

These tests are important for hypothesis testing, where data normality cannot be assumed.

Advantages of Non-Parametric Testing

The primary advantage of non-parametric testing in semiconductor testing lies in its flexibility. These tests can be applied to a wider range of data types and distributions, making them particularly useful for outlier detection and process control when parametric tests are unsuitable.

Non-parametric tests are less affected by outliers and can provide a more accurate picture of the underlying data characteristics. This flexibility is especially beneficial in semiconductor chip testing, where diverse data types and distributions are common.

Limitations of Non-Parametric Testing

However, non-parametric tests have their limitations. One of the main drawbacks is that they generally have less statistical power than parametric tests, particularly when dealing with large sample sizes and when the data follows a normal distribution. This means non-parametric tests might not detect subtle differences that parametric tests could identify.

When to Use Parametric vs Non-Parametric Tests

Several factors influence the choice between parametric and non-parametric tests in semiconductor testing. Parametric tests are preferred when the data follows a normal distribution and other assumptions, like homogeneity of variances, are met.

These conditions are often fulfilled in controlled manufacturing environments with tightly regulated process variables. When these conditions are present, parametric testing suits hypothesis testing and statistical inference, offering more power and precision.

In contrast, non-parametric tests are the go-to choice in scenarios where the data does not meet these assumptions. This includes situations with small sample sizes, ordinal data, or when the data distribution is unknown or non-normal.

Non-parametric tests are also beneficial for outlier detection. Their robustness against outliers can provide a more accurate analysis of semiconductor characterization.

Case Study: Parametric Testing in High-Volume Semiconductor Manufacturing

A real-world case study exemplifying parametric tests in semiconductor technology involves implementing in-line electrical tests, measurement, and analysis to reduce wafer loss and costs. This approach, undertaken by Imec Semiconductor Technology and Systems Group, reduced fab cycle time by 3X using dedicated parallel SMU channels.

The method significantly improved system capabilities by implementing flexible test and measurement routines, showcasing the effectiveness of parametric tests in enhancing semiconductor process flow and reducing test time

Impact on Semiconductor Quality and Reliability

Implementing parametric and non-parametric testing plays a vital role in quality assurance. Manufacturers can precisely assess semiconductor chips against specific parameters essential for maintaining data integrity and consistent manufacturing yield using parametric testing.

On the other hand, non-parametric testing is key in scenarios where the assumptions necessary for parametric tests do not apply. This includes cases with small sample sizes, different data distributions, or when ordinal data is involved.

Predicting Reliability

Predicting the reliability of semiconductor chips is a complex task that requires detailed analysis and testing. Parametric and non-parametric testing methodologies contribute significantly to this predictive process. It provides a framework for predicting lifespan and performance based on established parameters and statistical models.

Integrating Parametric and Non-Parametric Test Analysis with yieldWerx Solutions

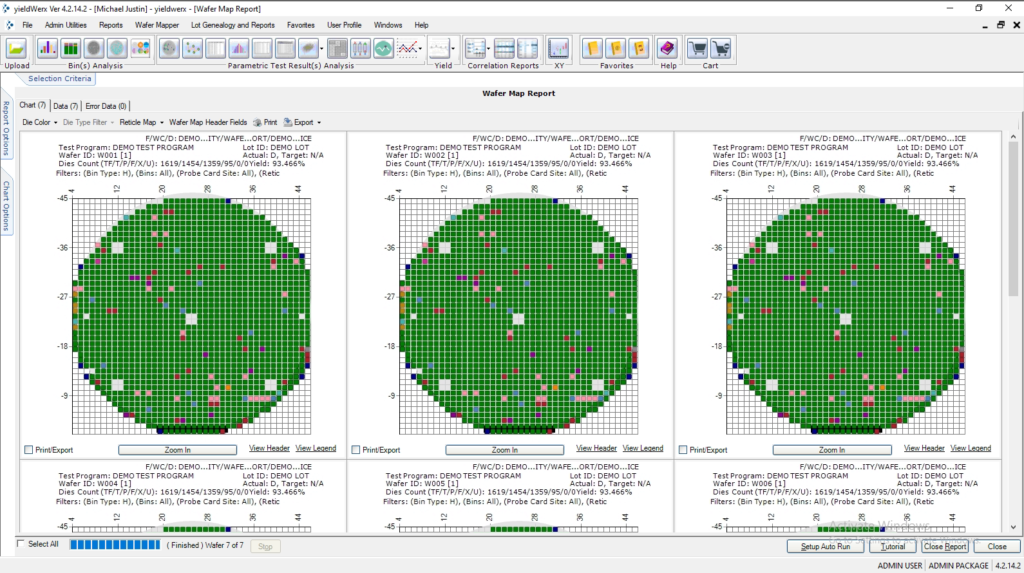

yieldWerx™ specializes in semiconductor test data analytics, which is critical in improving semiconductor production efficiency. Their services merge parametric and non-parametric test analysis to improve semiconductor product yield and quality.

Automated Testing and Yield Management Systems (YMS)

yieldWerx offers automated testing solutions critical for identifying defects in semiconductor chips. This is vital as semiconductors become more complex and demand increases in various industries, including automotive, medical, aerospace, and healthcare.

Live Data Analysis and Alerts

The system supports real-time monitoring and analysis, which is key for semiconductor manufacturing. Early detection of production issues can significantly affect product quality and yield.

Comprehensive Reporting and Analysis Module

yieldWerx’s Reporting & Analysis module enables semiconductor manufacturers to generate accurate real-time reports. It automates over 300 standard reports, providing detailed analysis of yield consistency, failure types, and correlations. The module also includes geospatial analysis and correlation analysis within wafer zones.

Support for Various Engineering Roles and Industries

yieldWerx caters to diverse engineering roles, including test equipment, product, quality, and yield enhancement engineers. The solutions apply to aerospace, defense, automotive, life sciences, consumer products, and fabless companies.

Custom Yield Management Solutions

yieldWerx provides flexible, end-to-end custom yield management solutions. These include automated data loading, raw data monitoring, standard access for external tools, and advanced features like inspection image and defect data management.

yieldWerx’s approach integrates advanced modules and techniques like Statistical Process Control (SPC), Part Average Test (PAT), and real-time anomaly detection, which are critical for modern semiconductor manufacturing and testing. Their solutions are designed to optimize manufacturing and testing processes, high-quality products, and comply with industry standards.

Conclusion

The exploration into parametric and non-parametric test analysis in semiconductors underscores their critical role in semiconductor components’ operational integrity and performance standards.

With solutions like those offered by yieldWerx, which combine both parametric and non-parametric test analyses, the industry is well-equipped to address these challenges, guaranteeing the continued advancement and reliability of semiconductor technologies.

Frequently Asked Questions (FAQs)

1. What distinguishes parametric testing from non-parametric testing in semiconductors?

Parametric testing assumes a specific data distribution, typically normal, while non-parametric testing does not rely on such assumptions.

2. Why is parametric testing crucial for semiconductor quality assurance?

Parametric testing offers precise analysis under known distribution assumptions, which is critical for consistent quality and performance in semiconductors.

3. How does non-parametric testing improve semiconductor chip testing?

Non-parametric testing offers flexibility for data without normal distribution, which is essential for varied and complex semiconductor testing scenarios.

4. What role do parametric and non-parametric tests play in predicting semiconductor reliability?

Both tests provide comprehensive data analysis, with parametric tests assessing under known conditions and non-parametric tests offering broader insights.