Multi Variant Part Average Test (MVPAT) for Refined Semiconductor Chip Manufacturing Analysis

The Multi Variant Part Average Test (MVPAT) is an innovative chip manufacturing analysis approach focusing on advanced quality control through multivariate testing and data-driven manufacturing, particularly for automotive electronics.

MVPAT integrates statistical process control, outlier detection, and data analysis to identify and mitigate variances in semiconductor fabrication processes.

By employing a combination of manufacturing analytics, part performance analysis, and test grouping, MVPAT provides actionable insights into the production line, contributing to production efficiency, quality, and yield optimization.

Why is MVPAT the Key to Advanced Quality Control?

MVPAT is a central and important advancement in semiconductor manufacturing, primarily due to its integration of multivariate testing and data analysis into quality control processes. This approach significantly enhances the ability to detect defects with precision levels that traditional single-variable tests cannot match.

Unmatched Defect Detection

MVPAT analyzes multiple variables and multiple devices on a single chip simultaneously, offering a detailed perspective on potential defects that surpass the capabilities of traditional quality control techniques.

This approach allows for a deeper understanding of the complex interactions between various manufacturing processes, leading to more effective identification and resolution of quality issues.

Optimizing Manufacturing Efficiency

Through precise defect detection and process analysis, MVPAT pinpoints specific areas where improvements are needed. This targeted approach reduces waste, optimizes production workflows, and reassures that resources are utilized more effectively.

MVPAT helps manufacturers achieve a more productive operation by focusing on critical factors influencing production quality.

Improved Yield Optimization

Implementing MVPAT in manufacturing directly contributes to yield optimization. Providing actionable insights based on past performance analysis and test grouping enables manufacturers to adjust their processes in real-time, significantly improving the yield of high-quality semiconductor chips.

This not only improves the reliability of the products but also contributes positively to the manufacturer’s bottom line by reducing the costs associated with defects and rework.

Reliable Quality Assurance

The advanced quality control techniques employed by MVPAT make sure that every semiconductor part adheres to the highest quality standards before it reaches the market.

By adopting MVPAT, semiconductor manufacturers can dramatically transform their production lines. This transformation is characterized by refined efficiency, advanced defect identification, enhanced yield from data-driven adjustments, and integrated quality assurance.

Integrating MVPAT For Optimizing Your Existing Chip QC Processes

Adopting MVPAT to improve existing semiconductor QC processes introduces an approach to identifying and correcting production issues. This method uplifts the precision of defect detection by utilizing statistical process control and multivariate analysis, targeting areas for process refinement.

The shift towards data-driven manufacturing under MVPAT boosts yield optimization and solidifies manufacturing efficiency, setting a new standard for quality control and assurance in the industry.

Evaluating Existing Quality Controls

Begin by conducting an in-depth review of your current quality control measures. Identifying these processes’ strengths and potential gaps is important for successfully integrating the Multi Variant Part Average Test (MVPAT).

It’s particularly important to assess the adequacy of your data collection techniques, as MVPAT relies heavily on a broad spectrum of high-quality manufacturing data for its advanced analysis.

Training on Multivariate Analysis Principles

Educating your quality control and engineering teams on the fundamentals of multivariate analysis and statistical process control is essential. Workshops or seminars that detail the methodology behind MVPAT, its reliance on outlier detection, and the significance of examining multiple variables concurrently will lay the groundwork for successful integration.

This education phase should underscore MVPAT’s ability to augment existing quality control frameworks by offering deeper, actionable insights into manufacturing processes.

Upgrading Data Collection Methods

To harness the full potential of MVPAT, you should refine or expand your data collection methods. This step could entail incorporating advanced sensor technology, enhancing data logging capabilities, or revising existing data collection protocols.

Deploying MVPAT Analytical Tools

Select and implement analytical software that supports MVPAT, making sure these tools can process extensive datasets and conduct complex statistical analyses. Compatibility with your current technological setup and accessibility for key staff are vital factors to consider during this phase.

Conducting Test Groupings and Performance Analyses

With MVPAT, tests or production stages are analyzed by grouping them and evaluating part performance within these groups. This approach aims to identify patterns or anomalies that suggest underlying process issues or emerging quality concerns.

Translating Insights into Action

Transform the insights gained from MVPAT analysis into tangible improvements within your quality control processes. This may involve adjustments to machinery, modifications to material specifications, or updates to production protocols. The objective is to apply data-driven decisions to enhance manufacturing efficiency and the quality of the end product.

Establishing Continuous Improvement Mechanisms

Create a system for ongoing evaluation and refinement of your production processes using insights derived from MVPAT. This continual review helps identify further improvement opportunities, guaranteeing that Part Average Testing remains a central component of your quality control strategy.

By methodically integrating MVPAT into your quality control practices, you can significantly improve your capacity for defect detection, process improvement, and manufacturing efficiency. MVPAT augments existing quality control measures with its advanced multivariate analysis and supports a data-driven approach to manufacturing excellence.

Industry-Specific Examples of MVPAT’s Impact

By employing multivariate testing, part performance analysis, and test grouping, MVPAT offers actionable insights that lead to superior quality assurance and control, setting a new standard for quality engineers. Let’s see how:

1. Quality Monitoring in Semiconductor Manufacturing

MVPAT’s capability for real-time quality monitoring has dramatically changed semiconductor manufacturing. By integrating manufacturing analytics, companies can continuously monitor the production line, adjusting parameters in real-time to guarantee the highest quality of chips.

This approach minimizes defects and significantly reduces the need for post-production quality checks, exemplifying advanced quality control and data-driven manufacturing.

2. Predictive Maintenance in Automotive Component Production

Machine Learning (ML) with MVPAT has revolutionized predictive maintenance in the automotive component manufacturing sector. By analyzing data points and trends from the production equipment, manufacturers can predict potential failures before they occur.

This proactive maintenance strategy minimizes downtime and guarantees a smooth production flow, demonstrating the substantial benefits of machine learning in enhancing PAT for manufacturing efficiency.

3. Simulation and Design Optimization in Aerospace Manufacturing

In aerospace manufacturing, MVPAT, enhanced with Artificial Intelligence (AI), has facilitated simulation and design optimization breakthroughs. By using AI to simulate various manufacturing scenarios, companies can optimize production methods for efficiency and quality before producing physical prototypes.

This innovative approach promotes significant advancements in manufacturing processes, allowing for the creation of more reliable and higher-quality aerospace components.

4. Supply Chain Management in Electronics Manufacturing

Robotic Process Automation (RPA) combined with MVPAT has provided tangible improvements in supply chain management within the electronics manufacturing industry. Automating back-office tasks and supply chain operations has led to more efficient, error-free processes.

This integration showcases the practical benefits of RPA in manufacturing, automating operations and allowing manufacturers to respond more quickly to market demands.

How yieldWerx’s MVPAT Can Help Improve Manufacturing Analysis

yieldWerx offers a tool for MVPAT that aims to optimize manufacturing analysis. It covers everything from real-time issue tracking and advanced outlier detection to deep root cause analysis and utilizing big data for a manufacturing overview.

It helps minimize defects and supports advancing manufacturing quality and operational efficiency, proving indispensable for manufacturers aiming for excellence.

Immediate Tracking of Production Anomalies

yieldWerx’s MVPAT technology marks a significant advancement in manufacturing by offering the capability to monitor production processes immediately.

This feature is vital for identifying and following up on issues, guaranteeing that production maintains high efficiency with reduced interruptions.

Outlier Detection

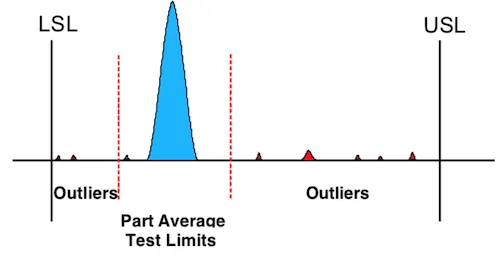

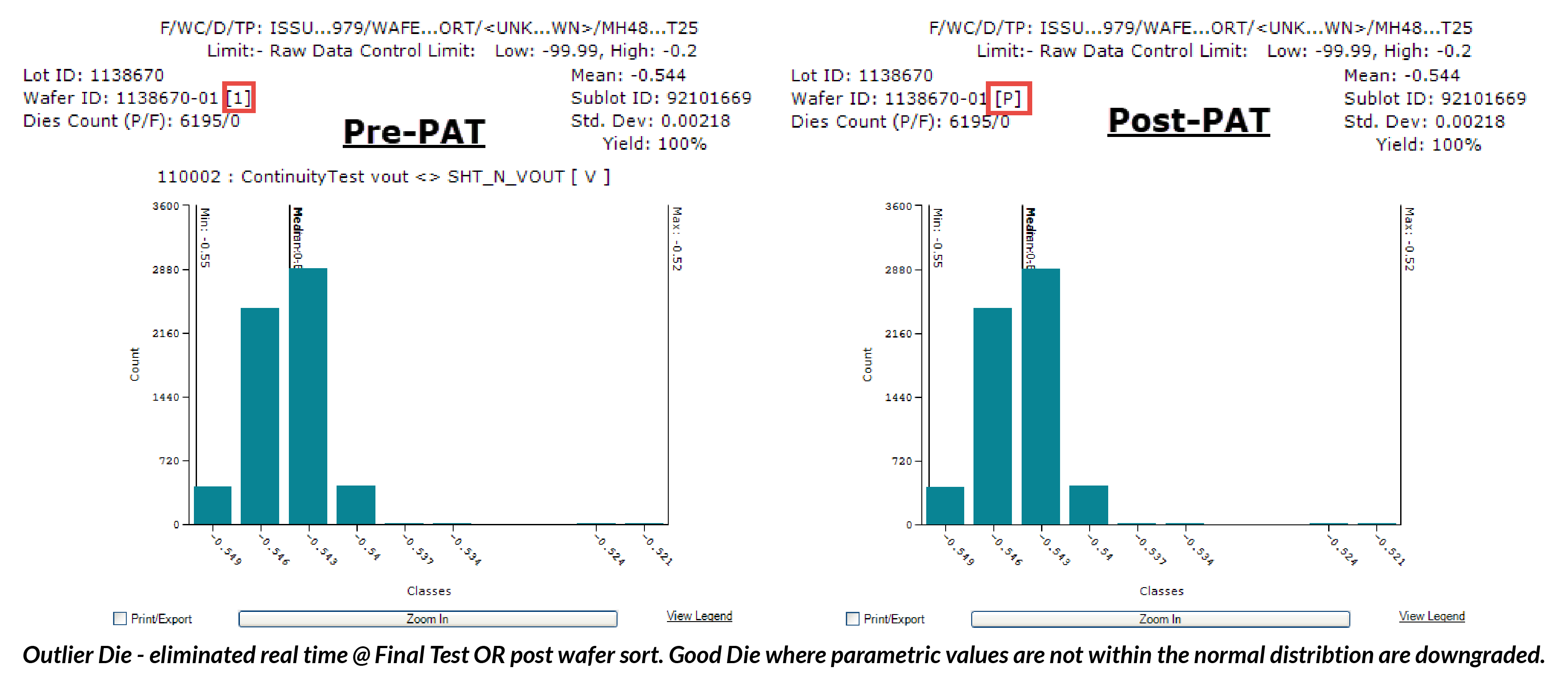

yieldWerx provides outlier detection, an effective system for detecting unusual patterns within the manufacturing workflow that might negatively impact yield.

This method is essential for keeping production quality consistent, signaling deviations from expected patterns that could compromise yield stability.

In-depth Analysis of Root Causes

A fundamental aspect of yieldWerx’s MVPAT is its in-depth analysis of root causes behind production problems.

Identifying the fundamental reasons for issues allows for crafting specific remedies that tackle the source of problems, leading to more lasting and impactful improvements in manufacturing processes.

Utilizing Big Data for Analysis

The MVPAT system capitalizes on big data analytics and supports various data formats, enabling exhaustive analysis of manufacturing information from diverse sources.

This adaptability guarantees that all available data, irrespective of its original format, can be effectively used to derive meaningful and actionable insights.

Minimizing Production Defects

Integrating analysis techniques and real-time process monitoring makes it feasible to address factors leading to defects.

Conclusion

Utilizing Multi Variant Part Average Test (MVPAT) in semiconductor manufacturing improves quality control and process efficiency. MVPAT’s real-time anomaly monitoring, advanced outlier identification, and detailed cause analysis redefine production optimization and defect management.

For further exploration into MVPAT’s transformative impact, yieldWerx provides in-depth insights into enhancing semiconductor manufacturing processes.

Frequently Asked Questions (FAQs)

1. How does MVPAT differ from other statistical process control (SPC) methods?

MVPAT focuses on the multivariate analysis of process parameters to detect shifts, unlike traditional SPC methods that monitor individual variables.

2. What data is required to implement MVPAT effectively?

To implement MVPAT effectively, engineers need comprehensive process and quality data across multiple variables, highlighting correlations and interactions between them.

3. What software tools are available for performing MVPAT analysis?

YieldWerx provides a comprehensive software suite specifically designed for MVPAT analysis in the semiconductor industry, offering powerful analytics and visualization tools.

4. How can MVPAT be integrated with existing quality management systems?

YieldWerx offers integration capabilities that allow MVPAT analysis to feed directly into existing quality management systems, ensuring seamless process optimization and quality control.

5. What are the limitations or challenges associated with using MVPAT?

The main limitations of MVPAT involve its complexity in setup and interpretation, requiring skilled personnel for effective use, and the potential for overlooking nuances in large data sets.

Recent Posts

- A Guide to Implementing Yield Management Software in the Semiconductor Industry

- Best Practices for Sensing Failures in Automotive ICs

- Why is Semiconductor Wafer Inspection Important?

- Multi Variant Part Average Test (MVPAT) for Refined Semiconductor Chip Manufacturing Analysis

- Wafer Map Calculators: Things You Should Know