Characterization Engineer (Design engineer for NPI)

For new product introduction (NPI) product engineers and design engineers verify IC design robustness when first silicon hits their respective test systems. They both need analysis tools to support the hurried environment which is fraught with the uncertainty of this question “Why is the design not working as expected? Is the test, design or manufacturing process at fault?”

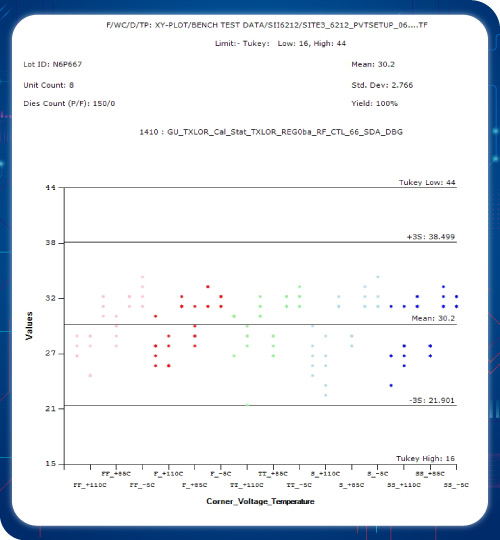

When looking at first silicon, design engineers use their knowledge of expected design performance to see if the measurements taken on their lab bench or the ATE match their simulation expectations. To do so with care they need to know where the handful of devices sit in the multi-variable process window. At first, they rely upon a bare bones test program to provide functional devices.

As product engineers add to the test program design engineers rely upon parametric measurements to understand their design’s true performance with respect to the on the manufacturing process.

In partnership with design engineers, product engineers verify chip design robustness and document the variance of important electrical measurements for a new IC or process through device characterization. Characterization analysis screens for process design interaction issues problems to ensure adequate yield to target specifications. Primarily performed on split lots, device characterization results are summarized in a characterization report that includes Cpk (process capability index), yield forecast data, and correlation analysis between operations (e.g., Probe vs. Final Test).

yieldWerx yield management software includes the distribution and correlation analytics needed to characterize devices and engineers efficiently generate the corresponding characterization reports.

Modules:

- Yield Calculation Flexibility

- Production Yield Reporting

- Standard Data Access for External Tool

- External Data Source Integration