Synopsis:

This module issues alerts to place lots on hold for lot disposition or direct lots to specific test programs. Alerts are based upon user-defined rules. Lot Commonality report capability is also provided.

Description:

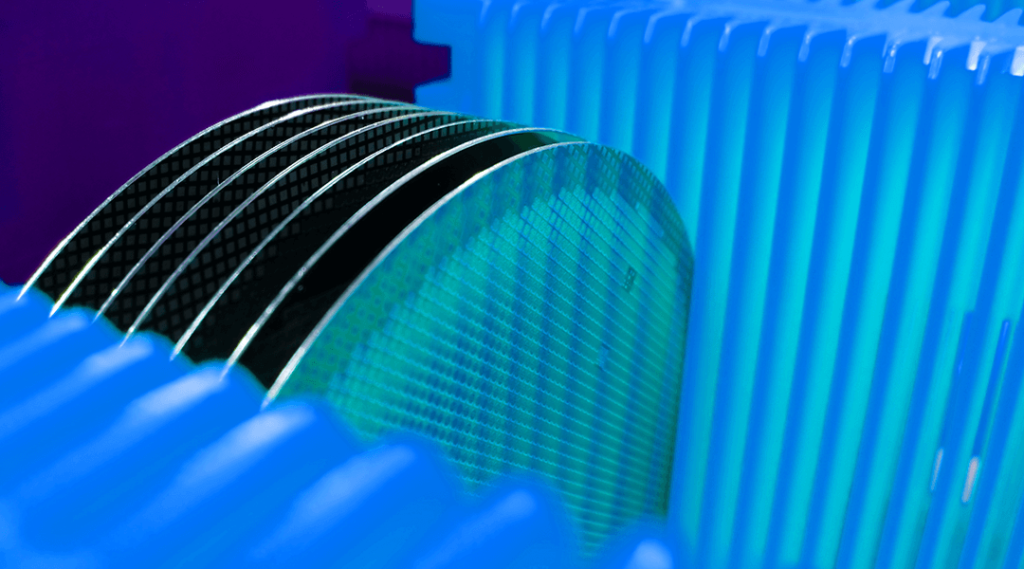

Identification of wafer or assembly lots that could be potentially bad remains a daily activity in any test manufacturing facility. The Real-Time Lot Control & Disposition module connects statistical control limits (bin limits, yield limits) with a facility’s MES automation software. Once alerted the engineer/operator assesses the available lot data to make one of the following decisions: scrap, retest, downgrade, release the lot for the next manufacturing step.

This module requires the user to document their reasoning behind their decision; this enables feedback in your facility’s operations.

Also, the user can execute a Lot Commonality report to identify other lots/wafers that may have similar manufacturing history. The report can inform if these lots/wafers have also been flagged for lot disposition.

The user will also be able to tag lots as Good, Bad, and Ugly with usages as follows:

- Good Lots -- to be used in correlation and commonality analysis.

- Bad lots – to be excluded (optionally) from calculating any historical trend and limits calculations.

- Ugly lots—to be excluded from any type of automated reports and analysis.

The reports supported by this module will flag which lots/wafers fall into which category on the outputs and the user can also filter them out on initial data selection.

Where applied:

Wafer and Final Test