Synopsis:

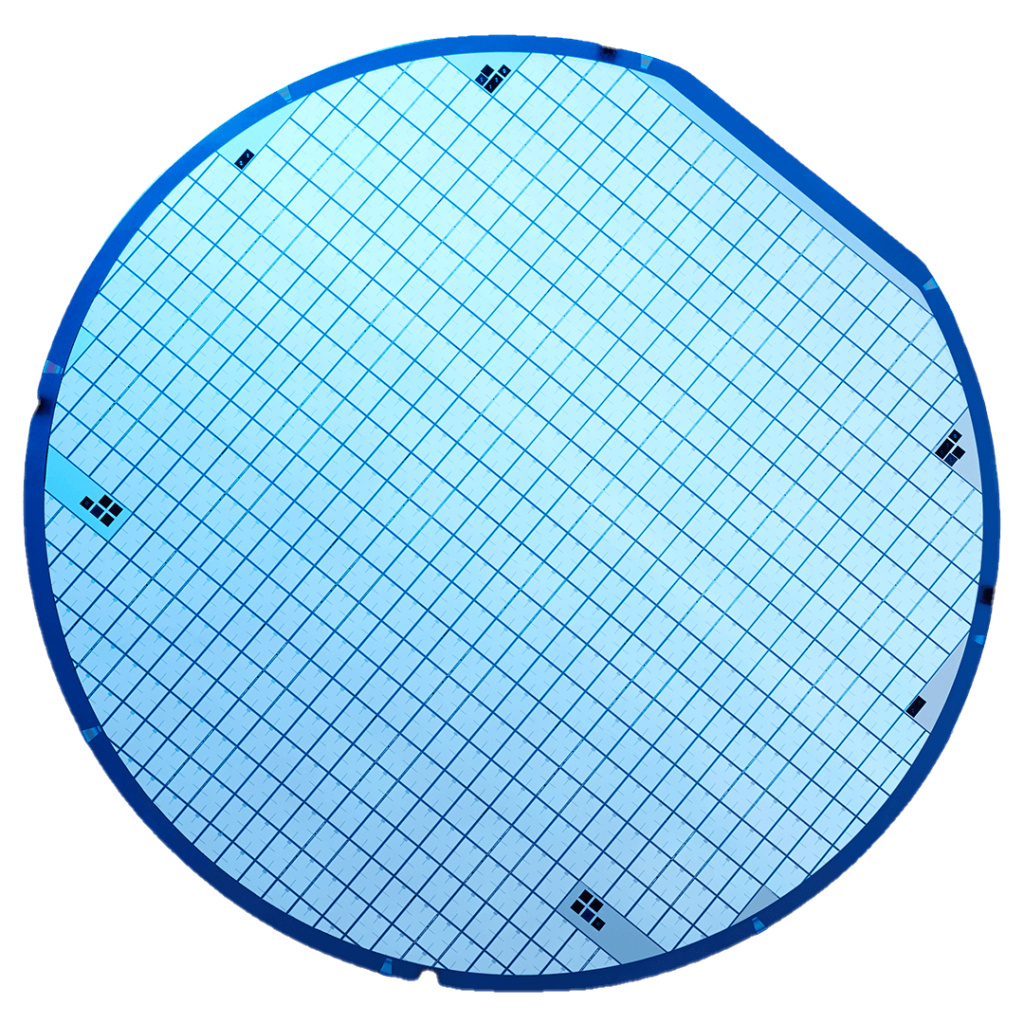

This module generates wafer maps that support automated optical inspection (AOI) and assembly steps in a variety of industry formats. It supports transferring these maps to the desired assembly site(s).

Description:

The transition between a wafer and a set of packaged units entails processing test data, inspection data, and manufacturing operational practices. Engineers and operators can use this module in conjunction with other yieldWerx modules to generate the required wafer map for inspection steps and assembly facilities. There exist a variety of formats for this data dictated by the equipment used to pick and place wafer die into the Lead-frames.

This module supports these formats and permits adding custom formats that may be needed to support legacy equipment. When integrated with your existing MES system “Lot End” signal initiates generating the assembly maps. Assembly map generation needs the flexibility to support a wide range of product situations and test data results. Also, engineers can modify test results with post-test analysis which changes a die from good to fail.

Engineering decisions could result in modifying the initial assembly map before transferring the wafers and their associated maps to the assembly facility. This includes results from AOI and for operation efficiency wafer test results can drive the AOI tool to only inspect good die. Engineers and operators can use this module to support such modifications. Several modification examples are provided to illustrate. Note these are not exhaustive in describing the capabilities of this module.

The wafer assembly map may simply indicate good die to be picked. Yet some wafers have mask reticles which contain four unique products which results in a more complex operation to be performed at the assembly site. For high reliability and quality requirements, e.g. automotive, engineers apply post-test decisions to identify outliers. This module can support such processing data from external sources that result in a modified map.

Your supply chain planners may dictate that three different OSATs will be used to support the packaging and final test of the product. Having automation capability to support this eliminates the need for manual intervention.

With performance binning data, the assembly map needs to indicate package type and even the customer to which packaged die will be shipped. In multi-chip package products engineers can have performance metrics with respect to die matching. This module supports these product performance scenarios.

New product introductions often require manual identification of units because design engineers value a partially functioning die during the silicon debug. During NPI engineers investigate performance in different package types and die selection may be blind or may be based upon a deliberate selection criterion.

Engineers, operators, and planners need a software tool to support communicating wafer map data for subsequent manufacturing steps- (wafer inspection, assembly, etc). Such a tool needs to combine wafer probe, post-test updates, and wafer inspection data to produce the final assembly map.

Engineering Roles Impacted:

- Product Engineer

- Characterization Engineer

- Supply Chain & Planning Owner/Manager

- Assembly Engineer, Process Engineer