Understanding the Significance of STDF Data in Semiconductor Testing

Accurate and efficient test data management is crucial in the semiconductor industry for maintaining high yields and ensuring product quality. Among the various formats used to store test data, the…

Overcoming Semiconductor Yield Management Challenges Using AI and ML

The semiconductor industry has come a long way from the days of simply sorting “good units” from “bad units.” Today, yield analysis dives deep into data science, uncovering many factors…

A Guide to Implementing Yield Management Software in the Semiconductor Industry

Optimizing yield is essential for operational efficiency and financial success. Yield management software significantly addresses these challenges, utilizing data analytics and machine learning to improve defect detection and process control….

Best Practices for Sensing Failures in Automotive ICs

The integration of semiconductor integrated circuits (ICs) in automotive systems has significantly advanced vehicle functionality and performance. These ICs are vital for a broad range of operations, from engine management…

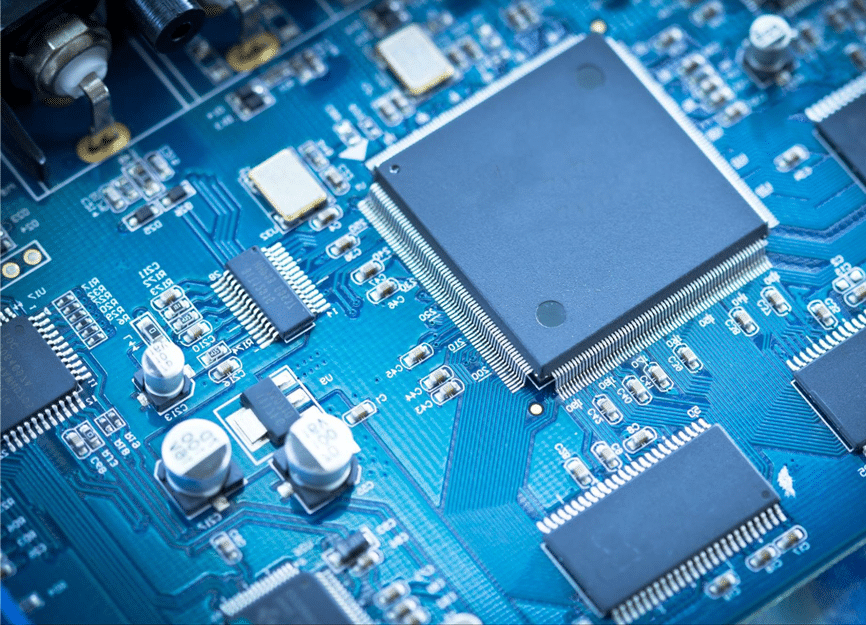

Why is Semiconductor Wafer Inspection Important?

Wafer inspection is one of the most remarkable steps in the production of semiconductor devices, as it verifies the accuracy and functionality of the wafers, which serve as the basis…

Multi Variant Part Average Test (MVPAT) for Refined Semiconductor Chip Manufacturing Analysis

The Multi Variant Part Average Test (MVPAT) is an innovative chip manufacturing analysis approach focusing on advanced quality control through multivariate testing and data-driven manufacturing, particularly for automotive electronics. MVPAT…

Wafer Map Calculators: Things You Should Know

Wafer map calculators are important for semiconductor manufacturing, playing a key role in optimizing production outcomes and improving yield. These calculators facilitate the gross die per wafer calculation, yield improvement,…

Understanding the Differences: Parametric vs Non-Parametric Test Analysis in Semiconductors

Distinguishing between parametric and non-parametric test analysis is essential for the functionality of semiconductor components. Testing methods are central to semiconductor chip testing and are critical in confirming these vital…

7 Ways Memory Technologies Benefit from Advanced Yield Management

Memory technologies such as DRAM and NAND Flash are critical components in digital devices, shaping the functionality and performance of everything from smartphones to servers. Manufacturing these technologies is highly…

A Comprehensive Guide to Boosting Gross Die Yield on Wafers in Semiconductor Manufacturing

Gross die yield, a critical metric in semiconductor manufacturing, reflects the proportion of functional chips produced from a wafer. It’s a key indicator of manufacturing efficiency, influencing the cost and…

Understanding GDBN in Semiconductor Manufacturing: A Comprehensive Guide

The concept of GDBN (Good Die in a Bad Neighborhood) is one of the critical aspects of semiconductor manufacturing. This term specifically refers to the occurrence where functional semiconductor dies…

Wafer Testing and Analysis: Ensuring Quality and Precision

Wafer testing is a key step in semiconductor manufacturing, verifying the high standards expected in today’s technology. This process checks the quality and performance of wafers, the thin slices of…