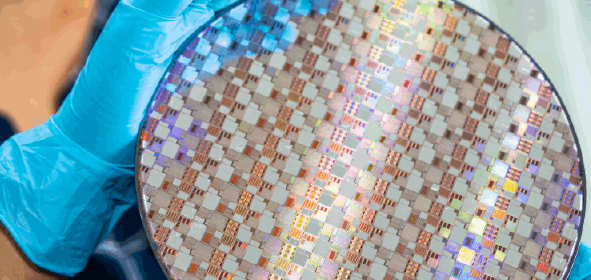

Wafer acceptance test (WAT) or commonly known as process control monitoring (PCM) data is the data that is collected at the last stage of wafer fabrication process. This data is taken directly from the various test structures placed on wafer’s predefined test sites. Usually, a set of multiple test structures is positioned for every reticule. Normally, a subset of various reticules with their pre-defined test structures are tested.

In most of the cases, this testing is treated as the wafer’s initial measurement of goodness or fit by the end customer of the product under testing. It becomes really difficult to evaluate and analyze the process control monitoring or wafer acceptance test data because of its limited availability but it is very important to analyze it as it helps the engineer forecast of issues and failure that may arise in the supply chain. These indications help in finding causes of failure that hampers yield and creates operational inefficiencies.

WAT Data Analysis with yieldWerx

yieldWerx’s powerful lot genealogy tool lets the users compare the test data throughout the manufacturing supply chain be it semiconductor wafer PCM data and its relationship with the semiconductor wafer sort test data or with the Semiconductor final test yield data. This comparison is made possible because of the data mapping and standardization methodology coded in the yieldWerx’s analytical suite. The user can view the genealogy tree of individual wafer or die and can evaluate its performance at the various nodes, thus by getting a view of the health of individual wafers and die with the help of few clicks.

The tool also allows the engineers to pinpoint equipment malfunction which may have caused false alarms of incorrect classification of good die as failing one. These capabilities of yieldWerx combined with the WAT/PCM data helps improve yield and removes operational inefficiencies from the system, making it worth the money for semiconductor companies.