How to Choose Your Analytics Path in Semiconductors: Cloud vs. On-Premises

Choosing the right data analytics path in the semiconductor industry is critical in terms of on-premises data centers and cloud computing. On the one hand, “on-prem” setups housed within an organization’s facilities offer unparalleled control and direct IT infrastructure management. This includes everything from hardware to data security, aligning closely with specific organizational needs and regulatory requirements.

On the other hand, cloud computing, characterized by its cost-efficiency and scalability, stands as a compelling alternative, especially for organizations looking to minimize upfront investments and adapt quickly to changing needs. The debate between on-prem and cloud computing is more than a choice of technologies—it’s a strategic decision impacting how semiconductor companies handle data, security, compliance, and scalability.

Let’s talk about how you can choose your analytics path in semiconductors.

Navigating Analytics in Semiconductor Manufacturing

In the semiconductor industry, optimal yield management is crucial for Fabs and OSATs striving for peak efficiency. Data management and computing approaches are continuously evolving. Industry leaders like Intel and GlobalFoundries are actively exploring and adopting various data management solutions, from traditional on-premises warehouses to cloud-based systems.

yieldWerxTM provides promising cloud analytics specializing in yield optimization software and offers a compelling solution. Start improving your processes today.

As data volume escalates, the choice between cloud and on-premises computing becomes crucialsignificant. Cloud computing, with its scalable and flexible infrastructure, is increasingly favored for its ability to handle vast datasets and complex analytics efficiently, crucial for timely defect identification and yield enhancement. On-premises solutions, while offering control and security, may not match the cloud’s agility and cost-effectiveness.

Cloud-Based Analytics in the Semiconductor Industry

Cloud-based analytics present a transformative approach, offering a robust solution to the cloud vs. on-premises debate. This shift is instrumental for semiconductor yield analysis and operational efficiency, allowing remote computing resources to manage and analyze data.

The scalability and adaptability of cloud solutions empower Fabs and OSATs to efficiently meet fluctuating data demands and computational requirements, all while minimizing capital expenditure. However, navigating the challenges of data security and consistent internet connectivity is crucial, considering the high stakes of data sensitivity and the necessity for continuous operations in the semiconductor industry.

Despite these hurdles, embracing cloud-based analytics for yield optimization and management could mark a strategic, forward-thinking move in the industry. Cloud services have made significant strides in security and compliance, addressing many concerns that semiconductor companies may have about data protection and regulatory compliance.

Advantages of Cloud-Based Solutions:

Scalability and Flexibility:

In the fast-paced semiconductor industry, Fabs and OSATs benefit immensely from the scalable nature of cloud-based solutions. These systems adeptly tune resource allocation to meet the shifting demands of yield data analysis, providing essential flexibility for entities amid rapid expansion or varying operational needs.

Cost Efficiency:

Cloud services are a game-changer when it comes to the financial viability of semiconductor operations, particularly for Fabs and OSATs. By eliminating the need for substantial upfront investments in hardware, the pay-as-you-go cloud computing model translates into significant cost savings, offering a lifeline to nascent firms and startups aiming to maximize resource efficiency.

Access to Advanced Technologies:

The cloud is a gateway to advanced analytics and superior computing capabilities for semiconductor companies. It democratizes access to cutting-edge tools necessary for comprehensive yield optimization and performance enhancement, allowing Fabs and OSATs to stay competitive and innovative without the burden of heavy internal IT investments.

Remote Accessibility

Test engineers using cloud-based systems can monitor and manage production from any device. They won’t be restricted to their work PC and won’t have to download large datasets to perform routine analysis. Instead, they can interact with the database directly using a command-line or graphical user interface on the move.

Exploring On-premises Analytics

The on-premises approach ensures stringent security and accurate control over proprietary information, aligning with the industry’s stringent standards for data handling. On-premises solutions empower companies to manage their yield data with heightened security, an indispensable factor for those dealing with confidential and proprietary semiconductor information.

However, this heightened control and security come at a cost, including significant initial investment in infrastructure and continuous expenditure in maintenance and skilled personnel. While on-premises systems offer unrivaled data control and security, they also necessitate substantial hardware investment and a team of experienced professionals, marking a significant consideration for Fabs and OSATs dedicated to optimizing and managing semiconductor yields.

Enhanced Data Security and Control via On-premises Computing

Data Security and Yield Confidentiality:

On-prem analytics offers unrivaled data security, a significant advantage for Fabs and OSATs in the semiconductor industry, where safeguarding yield data and intellectual property is crucial. Keeping sensitive yield data on-prem minimizes the risk of external breaches and unauthorized access, offering a fortified barrier against potential threats and ensuring a competitive edge in yield optimization.

Autonomy in Yield Data Management:

Maintaining an in-house data analytics infrastructure empowers semiconductor companies with full authority over their systems. This autonomy is essential for modifying analytics to meet the unique demands of yield optimization and management, allowing Fabs and OSATs to refine their systems for precise yield failure analysis and maximize operational efficacy.

Compliance and Regulatory Mastery:

On-premises analytics makes navigating the complex landscape of industry regulations easier. For semiconductor companies, particularly Fabs and OSATs, managing yield data within their infrastructure simplifies adherence to stringent industry standards, mitigating legal and financial risks associated with non-compliance.

Guaranteed Performance and Dependability:

The consistent performance and reliability of on-premises analytics are invaluable in the semiconductor industry, where any downtime can translate into substantial losses. Fabs and OSATs can fine-tune their systems for peak efficiency, ensuring reliable and timely yield data processing. This steadfast performance is critical for real-time yield failure analysis, where swift and accurate data interpretation is paramount in averting costly production setbacks.

Key Factors to Consider When Choosing Between Cloud and On-premises Analytics

When deliberating between cloud vs. on-premises analytics in the semiconductor industry, several key factors need to be evaluated:

Data Security for Yield Optimization:

Navigating data security intricacies is critical, particularly for Fabs and OSATs engaged in yield optimization. On-premises setups offer robust control for managing sensitive data in semiconductor yield analysis. Despite this, with their extensive security investments and advanced protocols, cloud solutions present a compelling case, often providing a security infrastructure that’s challenging for on-premises systems to match.

Cost Implications in Yield Management:

Balancing costs is essential, especially in the capital-intensive semiconductor industry. Cloud services, with their pay-as-you-go model, reduce upfront expenses, offering an attractive proposition for yield management. Despite higher initial costs, on-premises solutions can provide more predictable financial planning, which is crucial for long-term yield analysis strategies.

Scalability and Flexibility in Yield Analysis:

Semiconductor yield management requires adaptable and scalable solutions. Cloud computing shines with its ability to swiftly adapt resources, an asset for the constantly evolving needs of yield analysis. Though on-premises systems offer stability and consistency, their rigidity can be a limitation compared to the dynamic scaling capabilities of cloud solutions.

Performance in Yield Optimization:

Performance evaluation is crucial, with the processing speed and efficiency directly impacting yield analysis outcomes. Cloud platforms like yieldWerx offer on-demand access to powerful computing resources like yield calculation flexibility and excel in efficiently managing large datasets and complex yield analysis tasks. On-premises systems, while reliable, may struggle to scale performance rapidly without extensive hardware investments.

Regulatory Compliance in Yield Management:

For Fabs and OSATs, adhering to industry regulations is paramount, especially in sensitive yield optimization processes. On-premises solutions provide direct oversight of compliance measures, offering peace of mind in regulatory adherence. However, leveraging cloud solutions necessitates thorough vetting of providers to ensure they meet the stringent regulatory standards essential in yield management.

How yieldWerx Bridges Cloud and On-Prem Solutions for Superior Semiconductor Analytics and Yield

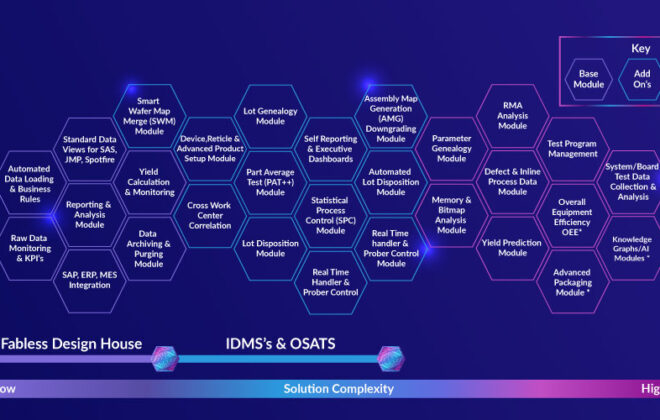

yieldWerx effectively addresses critical challenges in semiconductor failure analysis by providing innovative and adaptable solutions. This platform integrates cloud-based and on-prem tools, offering a versatile approach to managing vast quantities of manufacturing data. This method accurately identifies failure causes and supports strategic decision-making and process optimization, catering to the semiconductor sector’s unique needs of fabless companies, OSATs, and IDMs.

Moreover, yieldWerx excels in semiconductor failure analysis using advanced analytics and machine learning algorithms. These technologies dive deep into manufacturing data, uncovering patterns and pinpointing failure causes with unprecedented accuracy. This capability is vital for reducing downtime and improving yield rates, directly impacting the bottom line.

Conclusion

The semiconductor industry’s choice between cloud-based and on-premises analytics hinges on balancing scalability, cost, data security, and performance needs. Companies must align their analytics strategy with specific operational goals and industry requirements.

Staying in line with the latest trends in semiconductor analytics is essential. Let yieldWerx be your partner in semiconductor analytics.

Recent Posts

- A Guide to Implementing Yield Management Software in the Semiconductor Industry

- Best Practices for Sensing Failures in Automotive ICs

- Why is Semiconductor Wafer Inspection Important?

- Multi Variant Part Average Test (MVPAT) for Refined Semiconductor Chip Manufacturing Analysis

- Wafer Map Calculators: Things You Should Know